A kind of preparation method of co-crystal maltitol and sorbitol and reaction kettle with temperature control system

A technology of maltitol and sorbitol, which is applied in the control field of sugar industry, can solve the problems of eutectic process temperature control and complex production equipment, maltitol is easy to absorb moisture, etc., achieve good social and economic benefits, simple preparation method, good mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of co-crystal maltitol and sorbitol, comprising the following steps:

[0047] (1) Melting sugar: Feed maltitol and sorbitol from the raw material feeding pipe according to the ratio of 1-5:1 in mass ratio, add them to the dissolving tank 2 in the kettle body 1, and then feed them from the raw material feeding pipe to the dissolving tank 2, add water, and pass heat medium into the jacket 4 to raise the temperature inside the kettle body 1 to 110-125 ° C, dissolve for 2-3 minutes, and obtain a mixed liquid of maltitol and sorbitol, turn over the seal of the bottom surface of the dissolution tank 2 2a Plate 8, open the filter hole, vacuum pump 10 to filter the mixed liquid, and set aside; wherein, the maltitol is crystalline maltitol or liquid maltitol with a purity of more than 95%, and the sorbitol is crystalline sorbitol or a liquid with a purity of 98%. The above liquid sorbitol;

[0048] (2) Vacuum sugar cooking: the mixed liquid in step (1) is f...

Embodiment 2

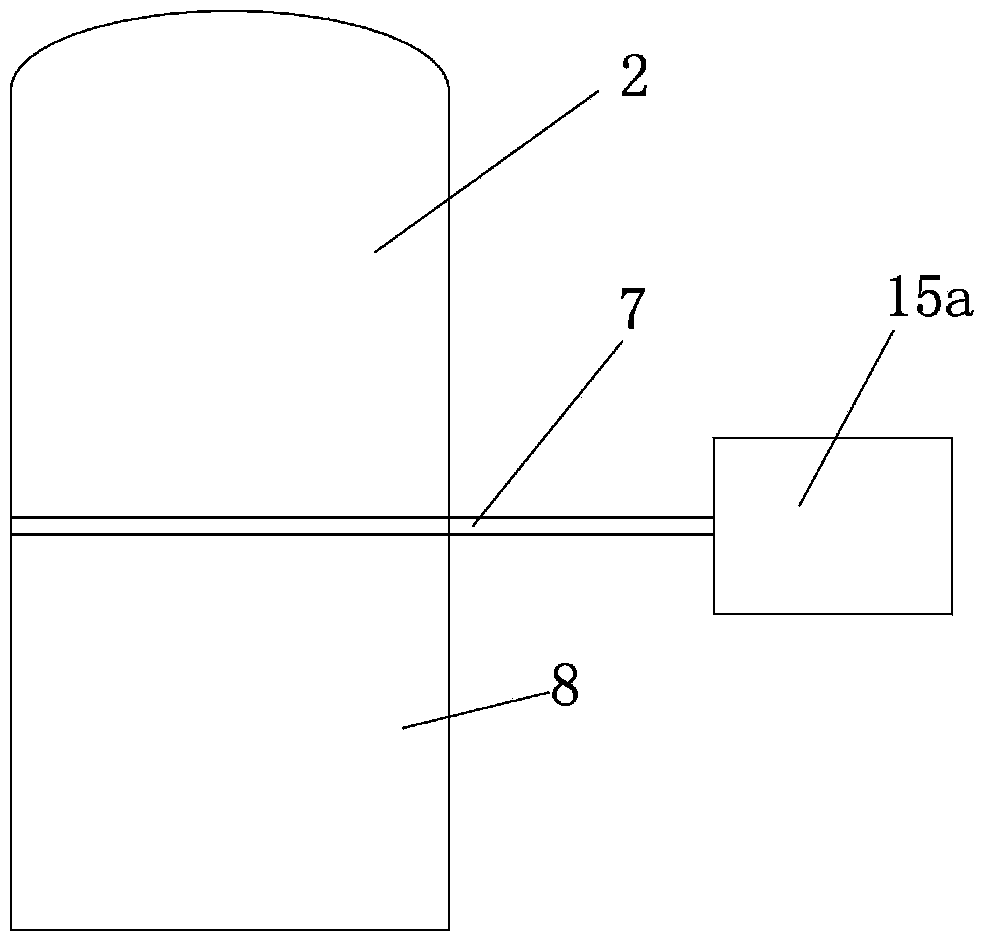

[0063] A kind of reactor with temperature control system, with reference to figure 1 , 2 , including the kettle body, the top of the kettle body 1 is provided with a dissolving tank 2, and the kettle body 1 is provided with a raw material feeding pipe communicating with the inner cavity of the dissolving tank 2, and there are 3 raw material feeding pipes, respectively It is the first feed pipe 3a for maltitol feed, the second feed pipe 3b for sorbitol feed and the third feed pipe 3c for adding water. The first flow sensor 17a of material flow, the bottom of described dissolving tank 2 cavity is provided with the first temperature sensor 14a that is used to detect solution temperature, and the bottom surface 2a of dissolving tank 2 has evenly distributed filter holes, dissolving tank 2 bottom surfaces The lower surface of 2a is covered with an overturned sealing plate 8, which is installed below the bottom surface 2a of the dissolution tank 2 through the rotating shaft 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com