Road and bridge concrete pavement repairing agent and preparation method thereof

A technology for concrete pavement and repair agent, applied in the field of building construction, can solve problems such as pavement cracks and broken plates, structural damage, lack of construction experience, etc., achieve good rust resistance, outstanding wear resistance and frost resistance, good Effects of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

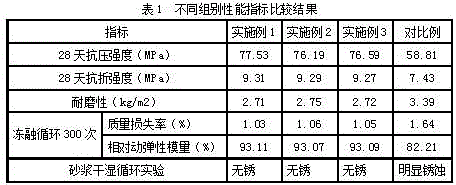

Examples

Embodiment 1

[0016] Embodiment 1: a, 16 kilograms of zinc oxide, 22 kilograms of kaolin of 4000 meshes, 24 kilograms of pyrophyllite of 325 meshes, length / diameter: 13 kilograms of the magnesium borate whiskers of 30~50 are added in the blender and mix uniformly, obtain mixed powder A;

[0017] b. 24 kg of MS-6070 ethylene-vinyl acetate copolymer redispersible latex powder from Shandong Gomez Chemical Co., Ltd., 2.5 kg of sodium palmitoyl glutamate, 3.2 kg of sodium tripolyphosphate, length: 6mm, Diameter: 5 kg of 13 μm polyacrylonitrile fiber, add it into the mixer and mix evenly to get mixed powder B;

[0018] c. Mix 60 kg of water with 4.5 kg of polycarboxylate superplasticizer powder and 2.2 kg of β-alanine from Suzhou Chenxiang Chemical Co., Ltd. to obtain mixture C;

[0019] d. Mix 110 kg of ordinary portland cement with mixed powder A and mixed powder B; then add mixture C and stir evenly.

Embodiment 2

[0020] Embodiment 2: a, 15 kilograms of zinc oxide, 21 kilograms of kaolin of 4000 meshes, 21 kilograms of pyrophyllite of 325 meshes, length / diameter: 12 kilograms of magnesium borate whiskers of 30~50 are added in the blender and mix evenly, obtain mixed powder A;

[0021] b. 21 kg of MS-6070 ethylene-vinyl acetate copolymer redispersible latex powder from Shandong Gomez Chemical Co., Ltd., 2 kg of sodium palmitoyl glutamate, 3 kg of sodium tripolyphosphate, length: 6mm, Diameter: 4 kg of 13 μm polyacrylonitrile fiber, add to the mixer and mix evenly to obtain mixed powder B;

[0022] c. Mix 50 kg of water with 4 kg of polycarboxylate superplasticizer powder of Suzhou Chenxiang Chemical Co., Ltd. and 2 kg of β-alanine to obtain mixture C;

[0023] d. Mix 100kg of ordinary portland cement with mixed powder A and mixed powder B; then add mixture C and stir evenly.

Embodiment 3

[0024] Embodiment 3: a, 20 kilograms of zinc oxide, 25 kilograms of kaolin of 4000 meshes, 25 kilograms of pyrophyllite of 325 meshes, length / diameter: 15 kilograms of magnesium borate whiskers of 30~50 are added in the blender and mix uniformly, obtain mixed powder A;

[0025] b. 25 kg of MS-6070 ethylene-vinyl acetate copolymer redispersible latex powder from Shandong Gomez Chemical Co., Ltd., 3 kg of sodium palmitoyl glutamate, 4 kg of sodium tripolyphosphate, length: 6 mm, Diameter: 6 kg of 13 μm polyacrylonitrile fiber, add to the mixer and mix evenly to obtain mixed powder B;

[0026] c. Mix 70 kilograms of water with 5 kilograms of polycarboxylate superplasticizer powder of Suzhou Chenxiang Chemical Co., Ltd. and 3 kilograms of β-alanine to obtain mixture C;

[0027] d. Mix 120kg of ordinary Portland cement with mixed powder A and mixed powder B; then add mixture C and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com