Enamel paint, preparation method thereof, and enamel product

A technology of enamel and coating, applied in the field of enamel, which can solve the problems of reducing the yield rate of enamel products, bursting, and enamel product explosion, etc., and achieves the effects of simple preparation process and construction process, improved coating performance, and increased bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

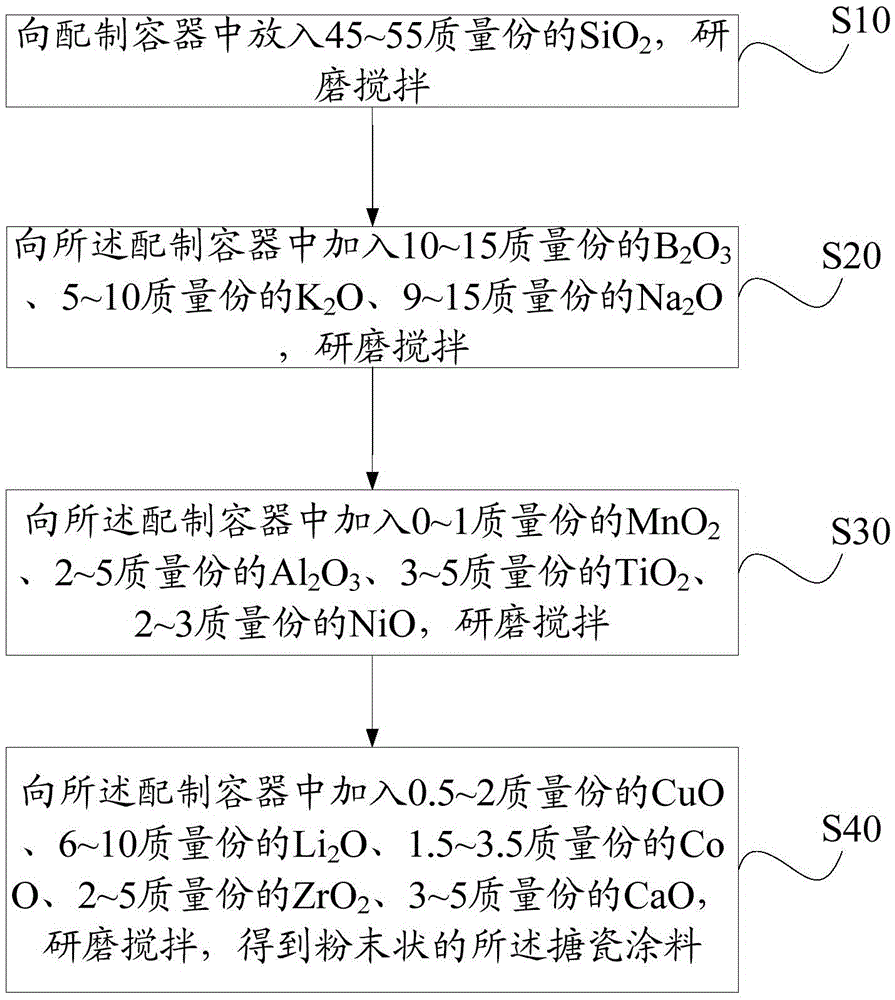

[0050] Such as figure 1 As shown, the preparation method of the enamel coating provided by the embodiment of the second aspect of the present invention is used to prepare the enamel coating of any one of the above-mentioned first aspect embodiments, comprising the following steps:

[0051] Step S10, put 45-55 parts by mass of SiO into the preparation container 2 , grinding and stirring;

[0052] Step S20, adding 10-15 parts by mass of B to the preparation container 2 o 3 , 5-10 parts by mass of K 2 O, 9 to 15 parts by mass of Na 2 O, grinding and stirring;

[0053] Step S30, adding 0-1 parts by mass of MnO into the preparation container 2 , 2 to 5 parts by mass of Al 2 o 3 , 3 to 5 parts by mass of TiO 2 , 2 to 3 parts by mass of NiO, ground and stirred;

[0054] Step S40, adding 0.5-2 parts by mass of CuO and 6-10 parts by mass of Li into the preparation container 2 O, 1.5-3.5 parts by mass of CoO, 2-5 parts by mass of ZrO 2 , 3 to 5 parts by mass of CaO, ground a...

Embodiment 1

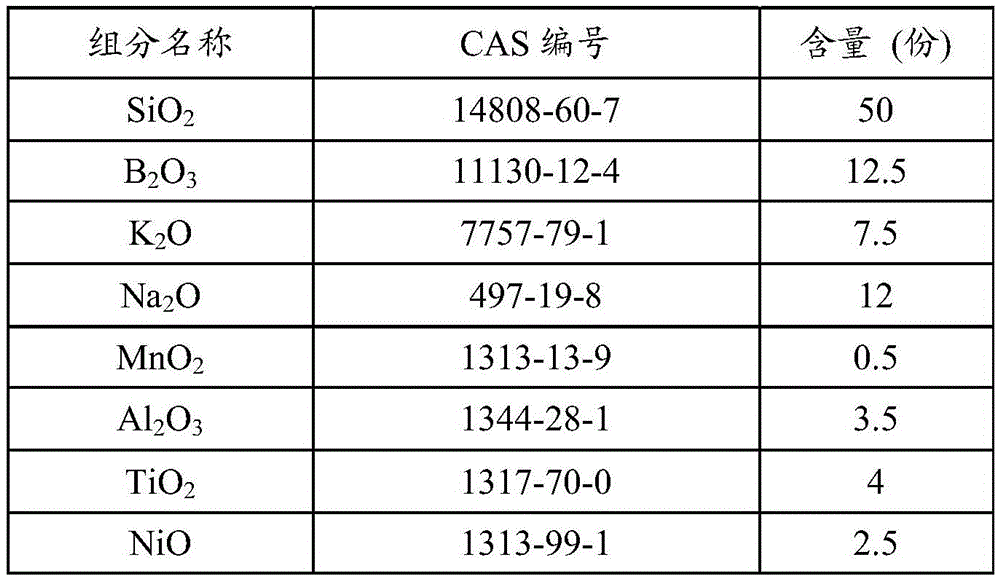

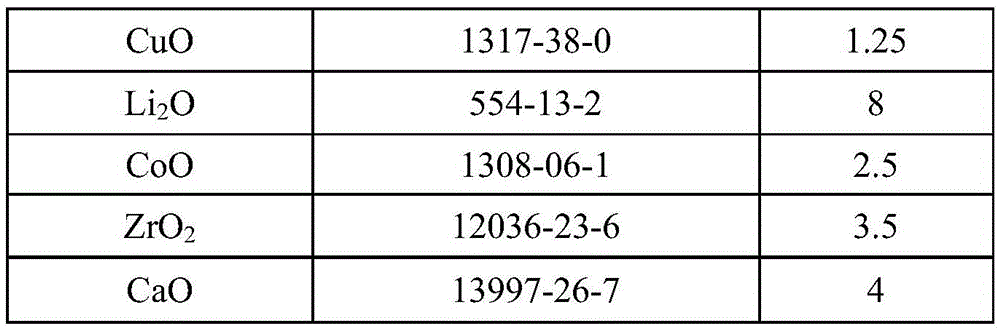

[0066] The components that the enamel coating in the present embodiment comprises and the mass parts of each component are:

[0067]

[0068]

Embodiment 2

[0070] The components that the enamel coating in the present embodiment comprises and the mass parts of each component are:

[0071] component name

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com