Method for keeping tension of packaging bag in packaging bag machining technology

A processing technology and packaging bag technology, which is applied in the field of maintaining the tension of the packaging bag in the packaging bag processing process, can solve the problems of unmaintained surface tension, unqualified packaging products, loose feeding, etc., and achieves the effect of reducing restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

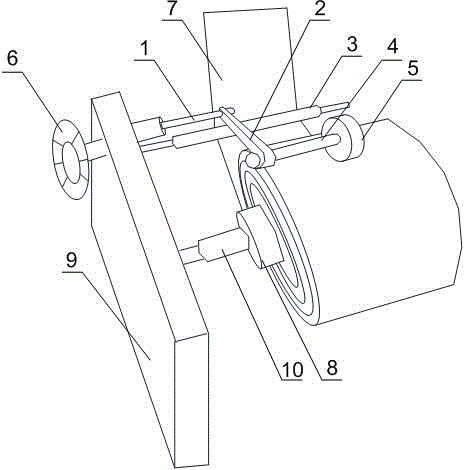

[0016] Such as figure 1 As shown, the present embodiment includes a guide roller 3 and a speed-limiting mechanism, and the guide roller 3 and the speed-limiting mechanism are respectively arranged on an external packaging machine 9, and the speed-limiting mechanism includes a support rod 1, a hand wheel 6, a connecting rod 2 and Press down device, one end of support bar 1 is hinged with the press down device by connecting rod 2, the other end of support bar 1 is screwed with handwheel 6, also includes the speed recorder 10 that is arranged on the cylinder of external packing machine 9. The guide roller 3 is separated from the cylinder 8 of the external packaging machine 9 by a certain distance, so that the packaging material 7 maintains a certain tension, and the speed limiting mechanism can control the rotational speed of the cylinder 8 of the external packaging machine 9, which acts as a speed limiter; The wheel 6 drives the support rod 1 to rotate, so that the pressing devi...

Embodiment 2

[0018] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the pressing device includes a roller 5 and a wheel handle 4 connected to each other, and the wheel handle 4 is connected to the support rod 1 through the connecting rod 2 . The set roller 5 can move together with the roller 8 of the external packaging machine 9, and the interaction force between the roller 5 and the roller 8 can be adjusted by adjusting the handwheel 6. The greater the frictional force between them, the greater the restriction on the speed at which the cylinder 8 rotates, and vice versa.

Embodiment 3

[0020] Such as figure 1 As shown, this embodiment is based on Embodiment 1 and Embodiment 2. As a preference, the roller 5 is a plastic roller. The texture of the roller 5 made of plastic is relatively soft, and when the relative force between the roller 5 and the roller 8 is relatively large, the roller 5 will not cause damage, imprints and other disturbances to the packaging material 7 .

[0021] Preferably, the connecting rod 2 is made of aluminum alloy. The connecting rod 2 is arranged between the pressing device and the support rod 1, and is used to connect and support the pressing device. The aluminum alloy material has strong hardness and light weight, which reduces the labor intensity when turning the handwheel 6. It also effectively avoids phenomena such as breakage and fracture of the connecting rod 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com