Adhesive device for rail fastener detection video equipment bracket

A technology for video equipment and track fasteners, applied in railway auxiliary equipment, vehicle parts, transportation and packaging, etc., can solve the problems of α-cyanoacrylate adhesive falling off, not much injection, low tolerance requirements, etc., to achieve α - Balanced dose of cyanoacrylate adhesive, enlarged area and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment, content of the invention will be further described:

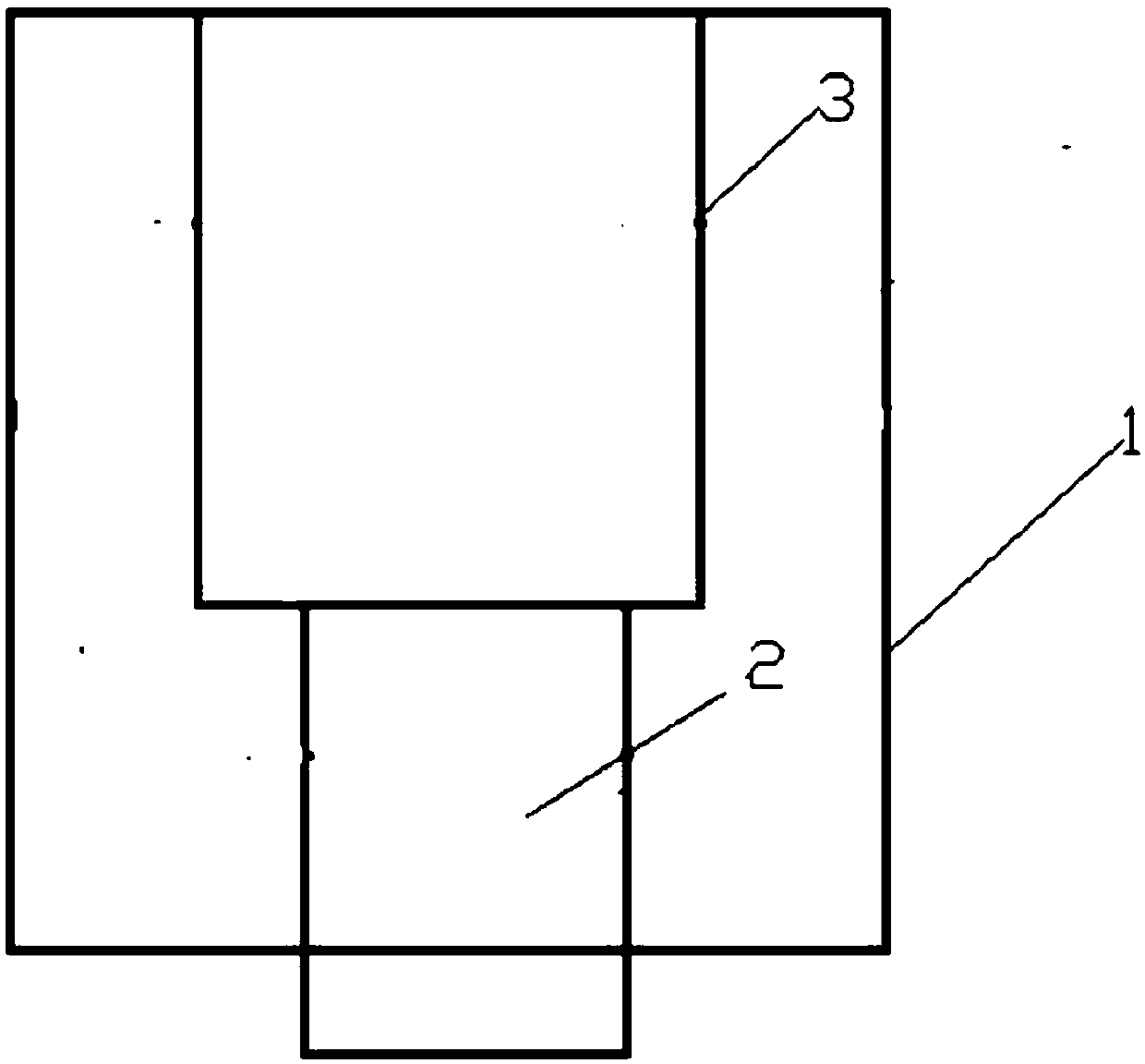

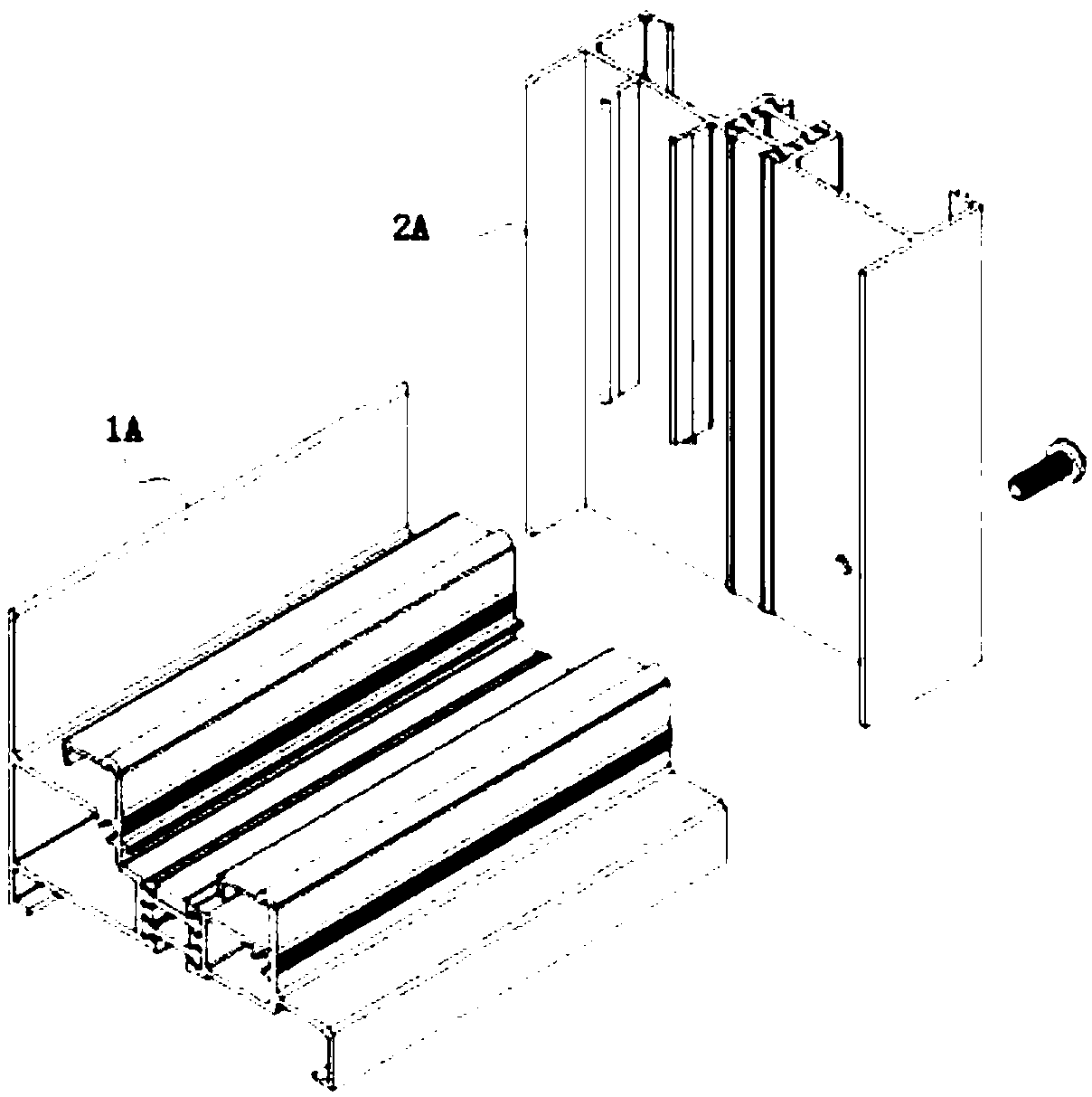

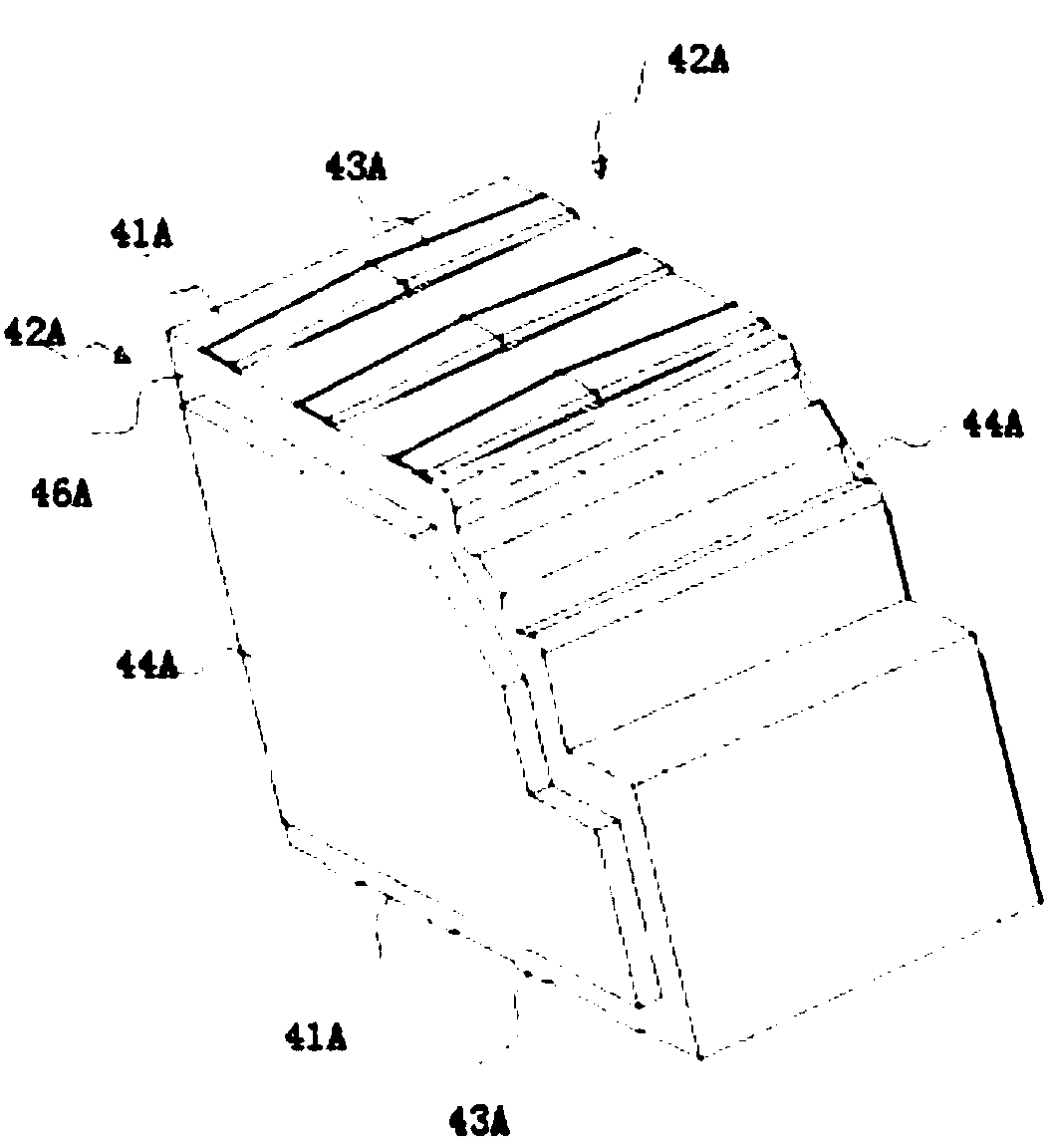

[0013] refer to Figure 1-Figure 3 As shown, the bonding device for the rail fastener detection video equipment support includes the car body 1 of the rail car, and a bracket 3 for erecting a video acquisition device 2 is arranged inside the car body 1 of the rail car, and the video acquisition The equipment 2 also protrudes from the bottom of the car body 1 of the rail car, and the support 3 is a cuboid frame structure, and the cuboid frame is formed by connecting a horizontal plate and a vertical plate from top to bottom, and the horizontal plate It is connected with the longitudinal plates through adhesives, and there are grooves on the outer walls of the transverse plate 1A and the longitudinal plate 2A. The adhesives are sheet-like structures, and the shape of the adhesives matches the grooves. , so that it can be put into the groove, the bonding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com