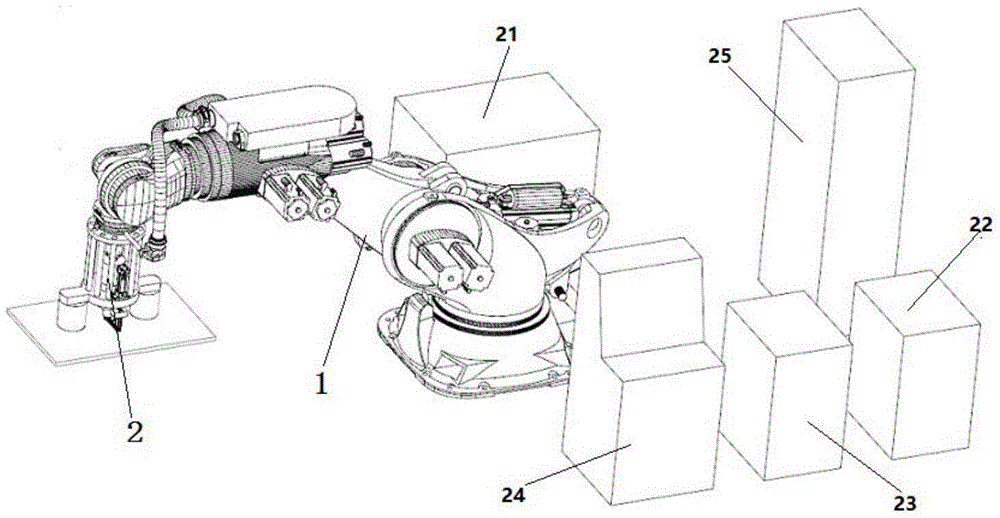

Compound robot heat source welding system by double methods of friction stud and friction stir

A friction stir and composite heat source technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as inability to complete, unable to meet intelligent, flexible manufacturing, and small application scope, saving equipment costs, The effect of improving welding efficiency and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

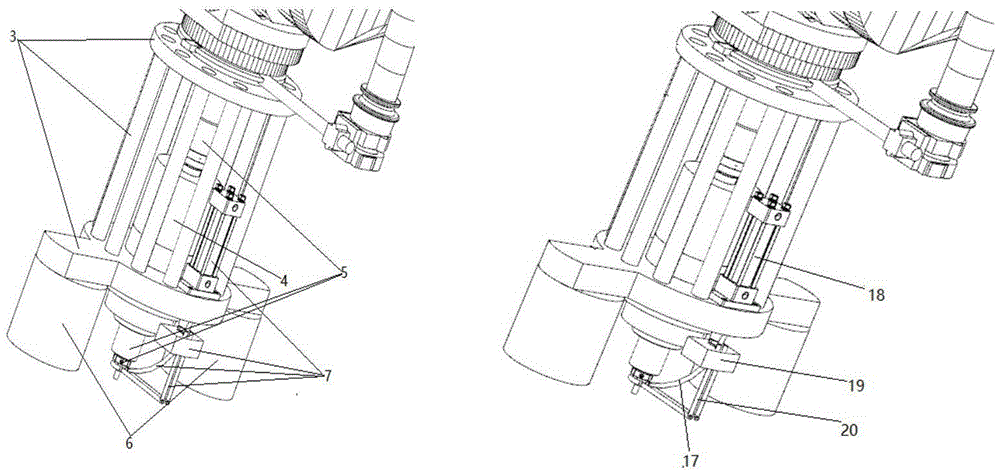

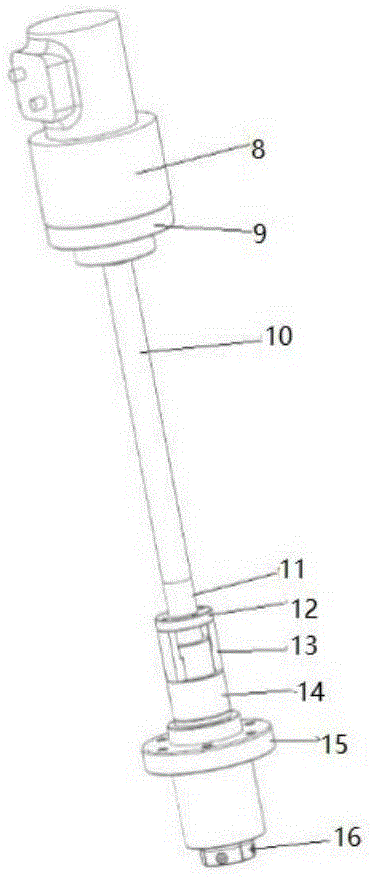

[0040] first step, such as image 3 As shown, the robot arm transports the collet 16 to the stud, and the preset program distributes signals to the hydraulic station 21 through the control cabinet 24 of the industrial computer, and the hydraulic station 21 controls the rotary cylinder 8 to pull the collet 16 upwards, thereby Automatically clamp the stud to complete the first step.

[0041] In the second step, the robot arm 1 drives the stud to move to the welding point. At this time, the induction coil 20 image 3 In the position shown, the industrial computer control cabinet 24 sends a signal to the hydraulic station 21 to control the hydraulic cylinder 18 of the induction coil 20 movement mechanism, thereby driving the induction coil 20 to move to the front end of the stud. Figure 4 Location.

[0042] In the third step, the induction coil 20 is energized to preheat the workpiece and the stud for a certain period of time, the spindle motor 4 is energized and rotates at a s...

Embodiment 2

[0045] In the first step, the welding head clamps the stirring needle, and drives the stirring needle and the induction coil 20 to move to the welding point. At this time, the induction coil 20 is Image 6 In the position shown, the workpiece is preheated for a certain period of time, and the protective gas is passed through the protective gas pipe 17 during the preheating process.

[0046] In the second step, the spindle motor 4 drives the stirring needle to rotate according to the set speed, and is pressed into the joint of the workpiece under the pressure of the mechanical arm 1. Figure 7 As shown, the friction stir welding is carried out along the butt joint, while the induction coil 20 preheats the unwelded butt joint, specifically as Figure 8 shown.

[0047] The third step, such as Figure 9 The shown friction stir welding is completed, the stirring needle leaves the weld, the induction coil 20 and the shielding gas of the shielding gas pipe 17 are closed, and the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Center hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com