Circular arc rolling equipment for square pipes

An arc and equipment technology, applied in the field of square tube arc rolling equipment, can solve the problems of labor and material, easy cracking, etc., and achieve the effect of reducing manual operation and avoiding easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

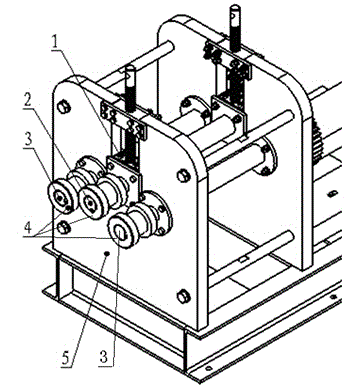

[0011] Combine below figure 1 The embodiment of the present invention is further described: a square tube arc rolling equipment includes: a sliding sleeve (1), an upper shaft (2), a lower shaft (3), and a pressure roller (4). The lower shaft (3) is fixed on the frame (5) by the bearing; the upper shaft (2) is installed on the sliding sleeve (1) through the bearing, and the sliding sleeve (1) controls the upper shaft (2) to move up and down; the upper shaft (2) 1. A pressure roller (4) is installed on the same-side shaft end of the lower shaft (3), and the outer surface of the pressure roller (4) is processed with a groove, which is suitable for the width of the square tube processed with an arc, and the square tube is controlled by the pressure roller In (4), it rotates with the rotation of the shaft, so as to realize the purpose of rolling the square tube into a circular arc.

[0012] The working principle of a square tube arc rolling equipment is: the groove width of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com