Processing method of Moringa Oleifera leaf tea

A processing method and technology of moringa leaves, applied in the field of new tea processing, can solve problems such as affecting the quality and taste of moringa leaf tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

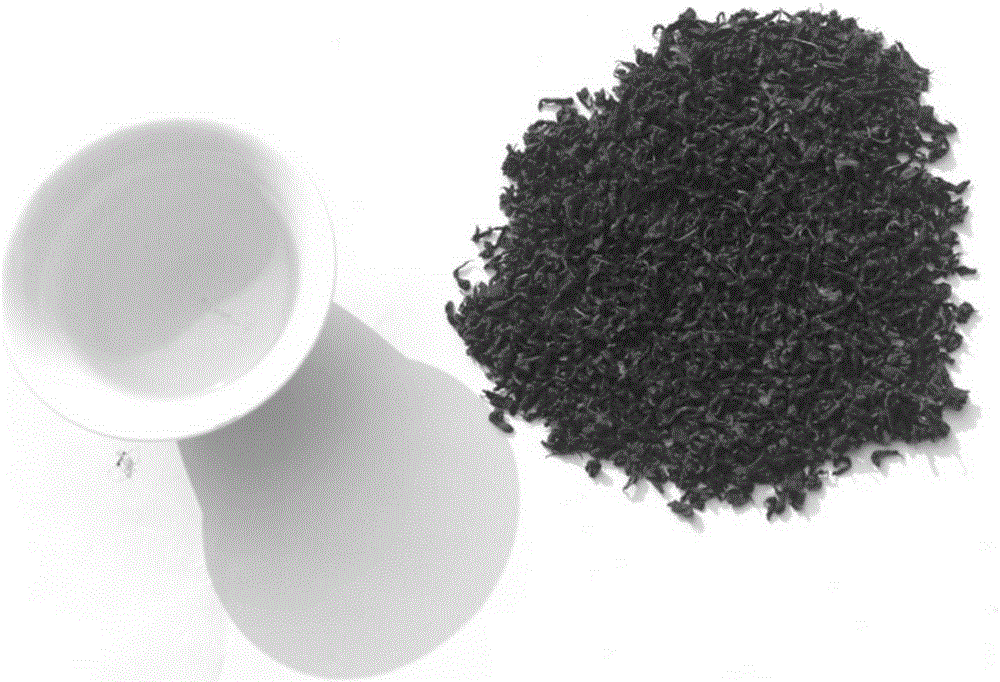

Image

Examples

Embodiment 1

[0021] A processing method of spring Moringa leaf tea, which sequentially comprises the steps of umami picking, withering, greening, greening, rolling, drying, aroma enhancement, and storage.

[0022] The step of picking fresh leaves includes picking fresh and mature leaves of Moringa oleifera without petioles and small petioles, and also does not contain Moringa oleifera flowers and moringa stalks;

[0023] The described withering step includes spreading the picked fresh leaves on a cool, dry and ventilated concrete floor or on a withering trough, the thickness of which is about 3cm, turning over 3-4 times during the period, and the spreading time is 3 Hour;

[0024] The step of greening includes: putting the withered fresh leaves into a green shaker, shaking the green leaves for the first time for 6 minutes, until the green taste is slightly apparent, taking them out and cooling them for 5 hours, touching the fresh leaves with hands When the green leaves are soft, shake the...

Embodiment 2

[0032] A method for processing summer moringa leaf tea, which sequentially includes the steps of umami picking, withering, greening, greening, rolling, drying, aroma enhancement, and storage.

[0033] The step of picking fresh leaves includes picking fresh and mature leaves of Moringa oleifera without petioles and small petioles, and also does not contain Moringa oleifera flowers and moringa stalks;

[0034] The step of withering includes spreading the picked fresh leaves on a cool, dry and ventilated concrete floor or on a withering trough, the thickness of which is about 5cm, turning over 5 times during the period, and the spreading time is 2 hours;

[0035] The described step of greening includes: putting the withered fresh leaves into a green shaker, and shaking the green leaves for the first time for 10 minutes, until the green taste is slightly apparent, taking them out and cooling them for 1 hour, touching the fresh leaves by hand When the green leaves are soft, shake t...

Embodiment 3

[0043] The invention discloses a method for processing moringa leaf tea in autumn, which sequentially includes the steps of umami picking, withering, greening, greening, rolling, drying, aroma enhancement, and storage.

[0044] The step of picking fresh leaves includes picking fresh and mature leaves of Moringa oleifera without petioles and small petioles, and also does not contain Moringa oleifera flowers and moringa stalks;

[0045] The withering step includes spreading the picked fresh leaves on a cool, dry and ventilated concrete floor or on a withering trough, the thickness of which is about 4cm, turning over 5 times during the period, and the spreading time is 2 hours;

[0046]The described step of greening includes: putting the withered fresh leaves into a green shaker, and shaking the green leaves for the first time for 5 minutes, until the green taste is slightly apparent, taking them out and cooling them for 1.5 hours, touching the fresh leaves by hand When the green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com