Medical instrument disinfectant and preparation method

A technology for medical devices and disinfectants, applied in the directions of disinfectants, biocides, bactericides, etc., can solve the problems of unsatisfactory disinfection effect, high content of chemical components, long disinfection time, etc. Long, good disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

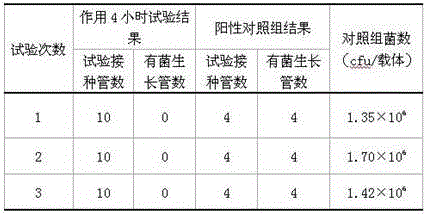

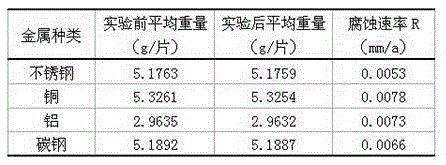

Examples

Embodiment 1

[0040] Example 1 Disinfectant for medical equipment, prepared from the following components in parts by weight (850g / part): 1 part of dibromohydantoin; 1.6 parts of paraformaldehyde; 8 parts; 6 parts of Eucalyptus glabra; 4 parts of Echinacea; 2.2 parts of ethylene oxide; 2 parts of Gemini quaternary ammonium salt; 0.5 part of trisodium phosphate chloride.

[0041] The preparation method of medical device disinfectant is:

[0042] (1) Mix Echeveria chinensis and Huanliangcao, add green tea water with 1.6 times the amount of the raw material and soak for 40 minutes, take it out, fry it with a slow fire, grind it into a fine powder together with disinfectant, pine and eucalyptus, and pass 35-mesh sieve to get mixed fine powder for later use;

[0043] (2) Soak the mixed fine powder obtained in step (1) in 70% ethanol at 50°C for 1 hour, wherein the amount of ethanol is 8 times the amount of the mixed fine powder, and then placed in an ultrasonic vibration extractor, Extract at ...

Embodiment 2

[0046] Example 2 Disinfectant for medical instruments, prepared from the following components by weight (650g / part): 2 parts of dibromohydantoin; 3.8 parts of paraformaldehyde; 12 parts; 8 parts of eucalyptus leaves; 7 parts of Echeveria chinensis; 3.8 parts of ethylene oxide; 3 parts of Gemini quaternary ammonium salt; 1.5 parts of trisodium phosphate chloride.

[0047] The preparation method of medical device disinfectant is:

[0048] (1) Mix Echeveria chinensis and Huanliangcao, add green tea water with 3.0 times the amount of the raw material and soak for 70 minutes, take it out, fry it with a slow fire, grind it into fine powder together with disinfectant, pine and eucalyptus, and pass 65-mesh sieve, mixed with fine powder for later use;

[0049] (2) Soak the mixed fine powder obtained in step (1) in 90% ethanol at 50°C for 4 hours, wherein the amount of ethanol is 16 times that of the mixed fine powder, and then placed in an ultrasonic vibration extractor, Extract at 4...

Embodiment 3

[0052] Example 3 Disinfectant for medical instruments, prepared from the following components by weight (800g / part): 1.3 parts of dibromohydantoin; 2.0 parts of paraformaldehyde; 9 parts; 6.5 parts of Eucalyptus glabra; 5 parts of Echeveria chinensis; 2.6 parts of ethylene oxide; 2.3 parts of Gemini quaternary ammonium salt; 0.8 part of trisodium phosphate chloride.

[0053] The preparation method of medical device disinfectant is:

[0054] (1) Mix Echeveria chinensis and Huanliangcao, add green tea water with 2.0 times the amount of the raw material and soak for 50 minutes, take it out, fry it with a slow fire, grind it into a fine powder together with disinfectant, pine and eucalyptus, and pass 45 mesh sieve, mixed fine powder for later use;

[0055] (2) Soak the mixed fine powder obtained in step (1) in 75% ethanol at 50°C for 1.5 hours, wherein the amount of ethanol is 10 times the amount of mixed fine powder, and then placed in an ultrasonic vibration extractor, Extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com