Evaporator temperature equalizing and cooling plate

An evaporator and cold plate technology, applied in the field of evaporative cooling devices, can solve problems such as uneven temperature of the cold plate, air blockage, etc., achieve the effect of reducing the quality of cooling work, avoiding air blockage of equipment, and ensuring consistent temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

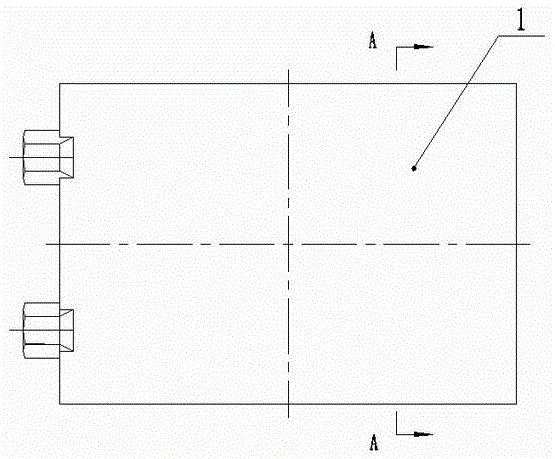

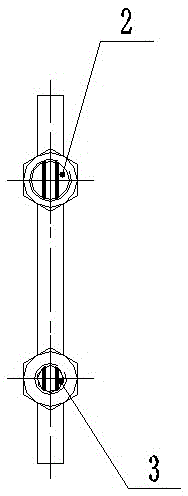

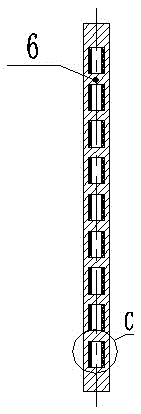

[0016] The specific content of the present invention is described in detail with reference to the accompanying drawings. An evaporator uniform temperature cold plate, comprising a cold plate wall 1, a sealing frame 7 arranged on the outer periphery of the cold plate wall 1, and a working fluid inlet 2 and a working fluid outlet 3 arranged on the sealing frame 7. The sealing frame 7 and the cold The plate wall 1 is connected by vacuum brazing, the working fluid inlet 2 and the working fluid outlet 3 are vacuum brazed and connected to the sealing frame 7. The internal cavity of the cold plate wall 1 is divided into a plurality of interconnected gas flow channels by reinforcing ribs 6 5. The gas flow channel 5 is filled with a working fluid, which is water or ethanol, and a capillary structure 4 is provided on the inner wall of the gas flow channel 5, and the capillary structure 4 is a sintered felt, a sintered mesh, and a sintered powder , Mechanically compress the wire mesh or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com