Switch tube clamping type transformerless photovoltaic inverter topology

A photovoltaic inverter and transformer technology, which is used in photovoltaic power generation, output power conversion devices, conversion of AC power input to DC power output, etc. Conducted and radiated interference and other problems, to achieve the effect of eliminating parasitic oscillation, suppressing leakage current capability, and suppressing common mode resonance phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

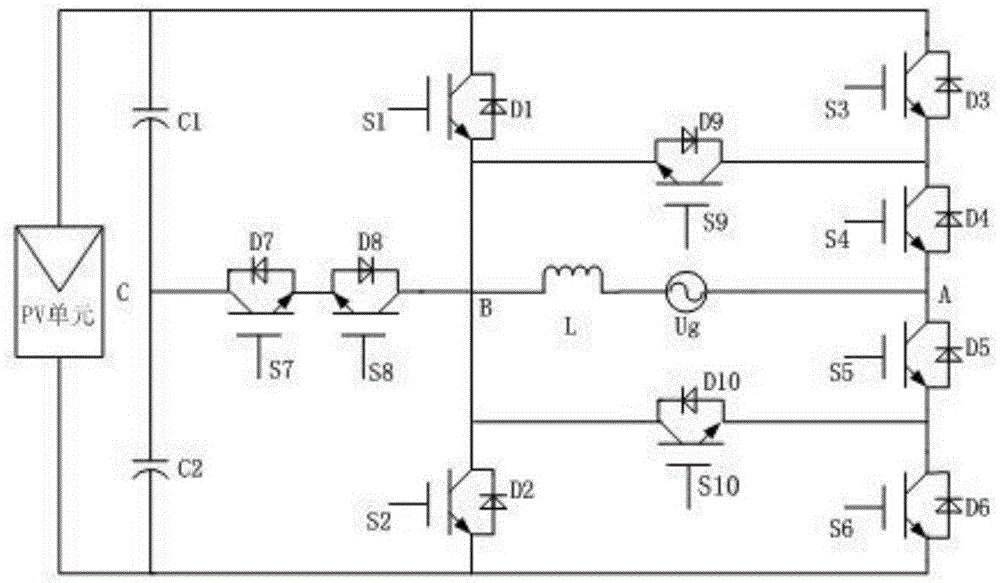

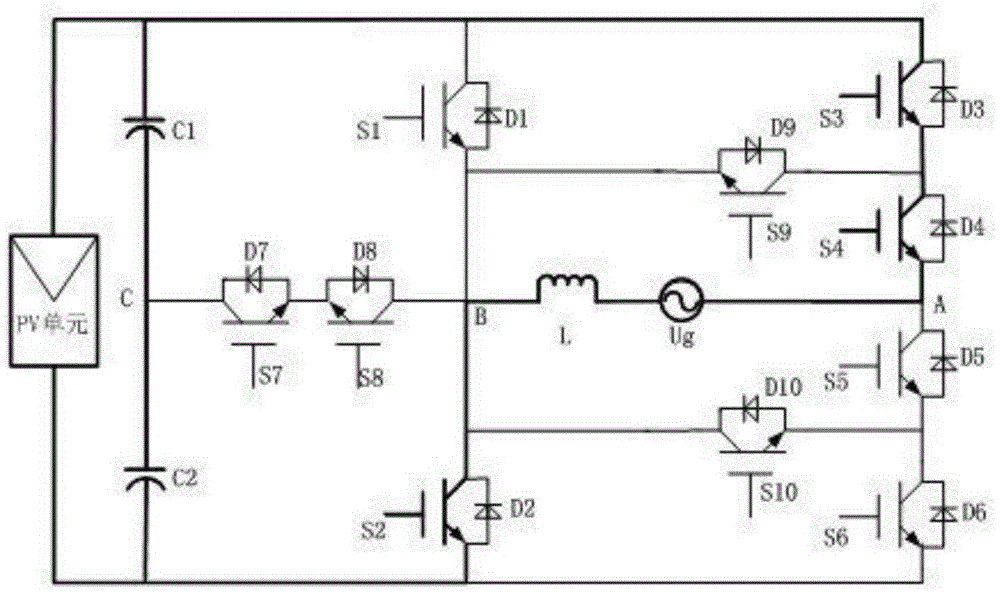

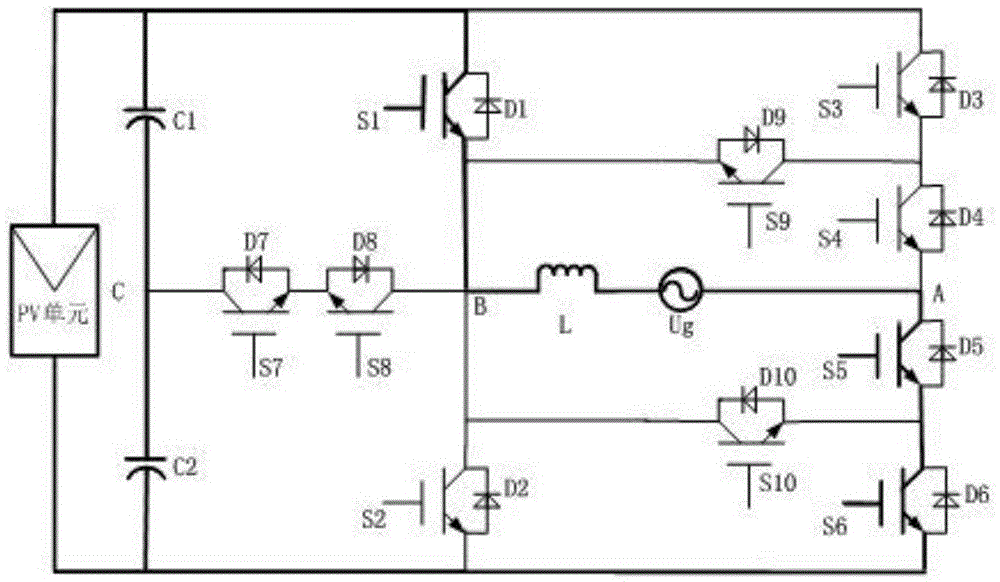

[0019] Working mode 1: Power switch tubes S2, S3, S4 are closed and the rest of the switch tubes are off, refer to figure 2 As shown, the A terminal of the inverter output is directly connected to the positive terminal of the PV side through the switch tubes S3 and S4, so the potential of the A terminal is the DC input voltage Ui; the B terminal of the inverter output is connected to the positive terminal of the PV side through the switch tube S2. The ground is connected, so the potential of the B terminal is zero, and the voltage U output by the inverter at this time AB is positive.

[0020] Working mode 2: Clamping switch tubes S7 and S8, power switch tube S4 and freewheeling switch tube S9 are closed and other switch tubes are turned off. If the power factor is equal to one, that is, the directions of voltage and current are the same, all are determined by A flows to B (transition from working mode 1 to working mode 2), and a freewheeling channel is formed through the dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com