Preparation method of active graphene/active carbon composite electrode plate

A composite electrode and graphene technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low solid content of electrode slurry, cracking and falling off of pole pieces, and low electrode density, so as to ensure continuity and thickness uniformity, increased electrode density, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

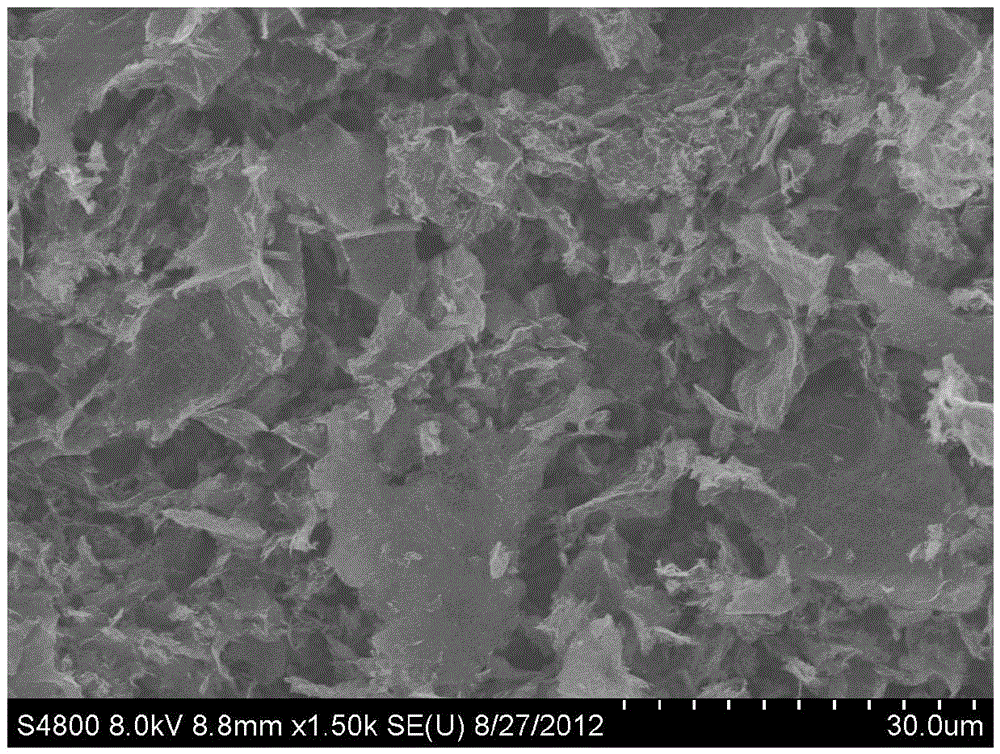

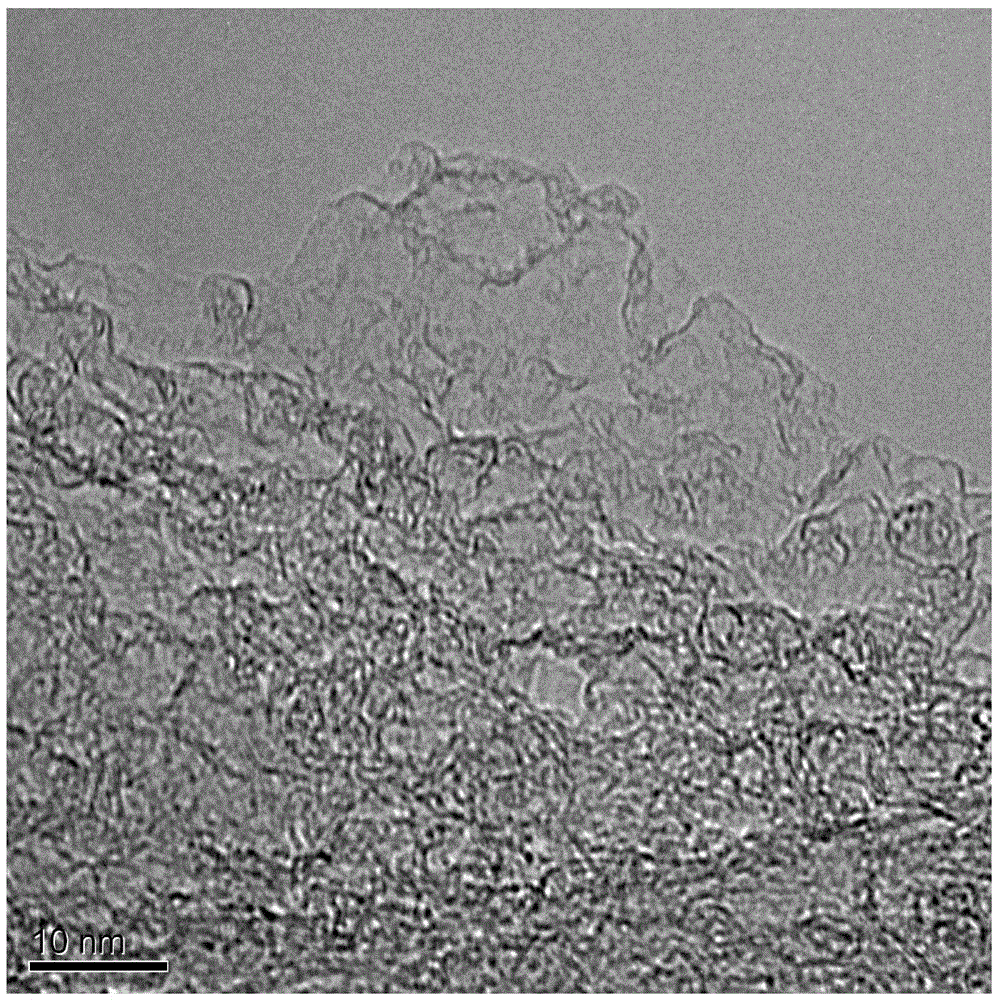

[0044] The reduced graphene prepared by chemical oxidation method and the pore-forming agent are mixed uniformly in a mass ratio of 1:8, and then immersed in an equal volume of water for 15 hours, and then dried. After drying, in an inert atmosphere at 960 ° C Activated for 1 hour, then washed with water, washed with 1M hydrochloric acid, washed with a large amount of water, and dried to obtain active graphene; wherein, the pore-forming agent is a composite pore-forming agent of potassium hydroxide and metallic nickel, and the composite pore-forming agent is The mass percentages of potassium hydroxide and metallic nickel are 90% and 10%; the particles of the active graphene are 8-9 μm, and the tap density is 0.3-0.4 g / cm 3 , the specific surface area is 1600-1800m 2 / g, the pore size is 3-5nm; the particle size of activated carbon is 7-10μm;

[0045] The activated carbon graphene and polyvinyl alcohol (PVA) are uniformly mixed according to the mass percentage of 98% and 2% re...

Embodiment 2

[0049] The reduced graphene prepared by the chemical oxidation method and the pore-forming agent are mixed uniformly in a mass ratio of 1:6, and then immersed in an equal volume of water for 12 hours, and then dried. After drying, in an inert atmosphere at 990 ° C Activated for 0.8 hours, then washed with water, washed with 1M hydrochloric acid, washed with a large amount of water, and dried to obtain active graphene; wherein, the pore-forming agent is potassium hydroxide; the particles of the active graphene are 8-9 μm, vibrating Solid density 0.3-0.4g / cm 3 , the specific surface area is 1600-1800m 2 / g, the pore size is 3-5nm; the particle size of activated carbon is 7-10μm;

[0050] Disperse the active graphene into a certain amount of dichlorobenzene (ODCB), and obtain the active graphene modified by the surface non-covalent bond through ultrasonic, centrifugation, drying and other steps;

[0051] The modified activated graphene and activated carbon are mixed with mass p...

Embodiment 3

[0054] The reduced graphene prepared by the chemical oxidation method and the pore-forming agent are mixed uniformly in a mass ratio of 1:9, and then immersed in an equal volume of water for 20 hours, and then dried. After drying, in an inert atmosphere at 940 ° C Activated for 1.5 hours, then washed with water, washed with 1M hydrochloric acid, washed with a large amount of water, and dried to obtain active graphene; wherein, the pore-forming agent is a composite pore-forming agent of potassium hydroxide and metallic nickel, and the composite pore-forming agent is The mass percentages of potassium hydroxide and metallic nickel are 95% and 5% respectively; the particles of the active graphene are 8-9 μm, and the tap density is 0.3-0.4 g / cm 3 , the specific surface area is 1600-1800m 2 / g, the pore size is 3-5nm; the particle size of activated carbon is 7-10μm;

[0055] Connect 4-bromophenyl group to active graphene by diazide reaction to obtain edge-modified active graphene; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com