An On-Line Monitoring System for Continuous Production of Large Length Optical Fiber Units

An optical fiber unit and monitoring system technology, which is applied in the field of continuous production online monitoring system for large-length optical fiber units, can solve the problems of enterprise loss, affecting the continuous production, waste of optical fiber units, etc., and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

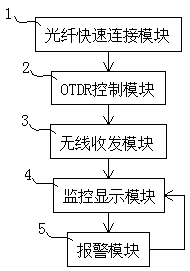

[0016] Such as figure 1 As shown, an on-line monitoring system for continuous production of large-length optical fiber units includes an optical fiber quick connection module 1, an OTDR control module 2, a wireless transceiver module 3, a monitoring display module 4 and an alarm module 5 connected in sequence;

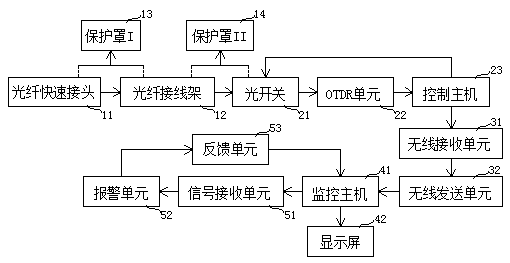

[0017] Such as figure 2 As shown, the fiber optic quick connection module 1 includes a fiber optic quick connector 11 and a fiber optic splice frame 12 for quick connection of the fiber optic unit, and the fiber optic quick connector 11 and the fiber optic splice frame 12 are protected by a protective cover I13;

[0018] OTDR control module 2 comprises optical switch 21, OTDR unit 22 and control main frame 23, in order to detect the on-off of the optical fiber in the optical fiber unit, the control end of control main frame 23 is connected with optical switch 21, and optical switch 21 and optical fiber splicing rack 12 pass protection Cover II14 protection;

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com