Method for detecting free amino acid in biogas slurry

A free amino acid and detection method technology, applied in the field of comprehensive development of biogas slurry, can solve the problems of unreasonable and safe treatment and disposal, and achieve the effect of avoiding selectivity, strong operability and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

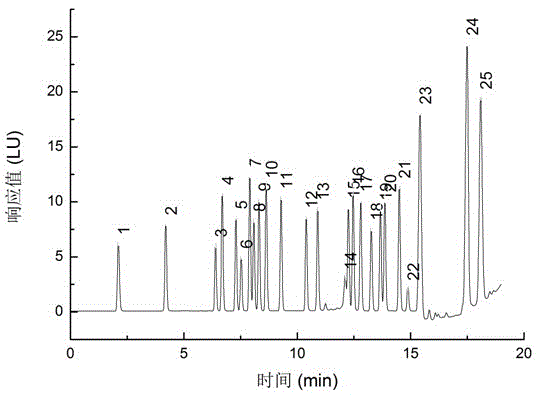

[0034] The biogas slurry discharged from the 6L sludge anaerobic digestion small test device with a solid content of 5% and 20% and the residual sludge fed into it were used as experimental materials. Pass all the biogas slurry above through a 0.22μm filter membrane to remove particulate matter, adjust the pH to 10.2 with 1M sodium hydroxide, take 5ml of the above biogas slurry in a 50ml rotary evaporating eggplant-shaped bottle, and vacuum rotary evaporation at 40 degrees Celsius to dryness To remove high-concentration ammonia nitrogen and volatile biogenic amines, redissolve with 5ml of 0.1M hydrochloric acid, and vortex for 30s to mix. Take 200 μL of the above-mentioned re-dissolution solution in a 0.5ML3KMliipore new ultrafiltration centrifuge tube, centrifuge at 13000g until all the liquid passes through, vortex mix and place at 4°C for use.

[0035] The above sample was automatically injected by Agilent HPLC1260 autosampler as follows: 0.5 μL mixed with 0.5 μL of OPA and...

Embodiment 2

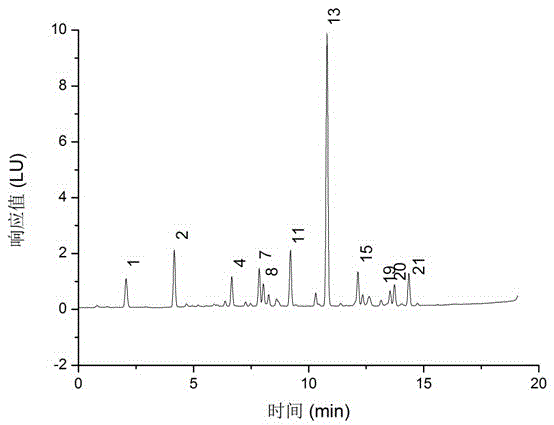

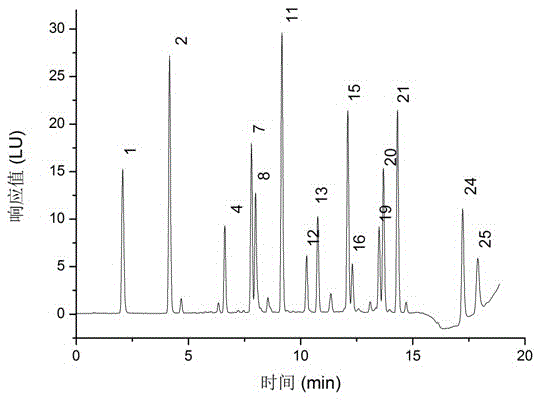

[0048] The biogas slurry discharged from the anaerobic digestion test device with a solid content of 10% was used as the experimental material. Biogas slurry samples were filtered through a 0.22 μm membrane filter. Filtered biogas slurry with 1mol L -1 NaOH solution to adjust the pH to 10.2, evaporate to dryness with 0.1mol L -1 HCL was re-dissolved; the sample used in the strong cationic solid-phase extraction (SCX-SPE) experiment was filtered and passed through 1mol·L -1 HCL adjusted the pH to 2.2 for use.

[0049] (1): SCX solid phase extraction cartridge experiment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com