High-sensitivity capacitive-type pressure sensor and manufacturing method therefor

A pressure sensor, capacitive technology, applied in the fluid pressure measurement, instrument, measuring force and other directions using capacitance change, can solve the problems of complex electrode extraction, difficult process, poor linearity, etc., to improve capacitance detection sensitivity, process Simple, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

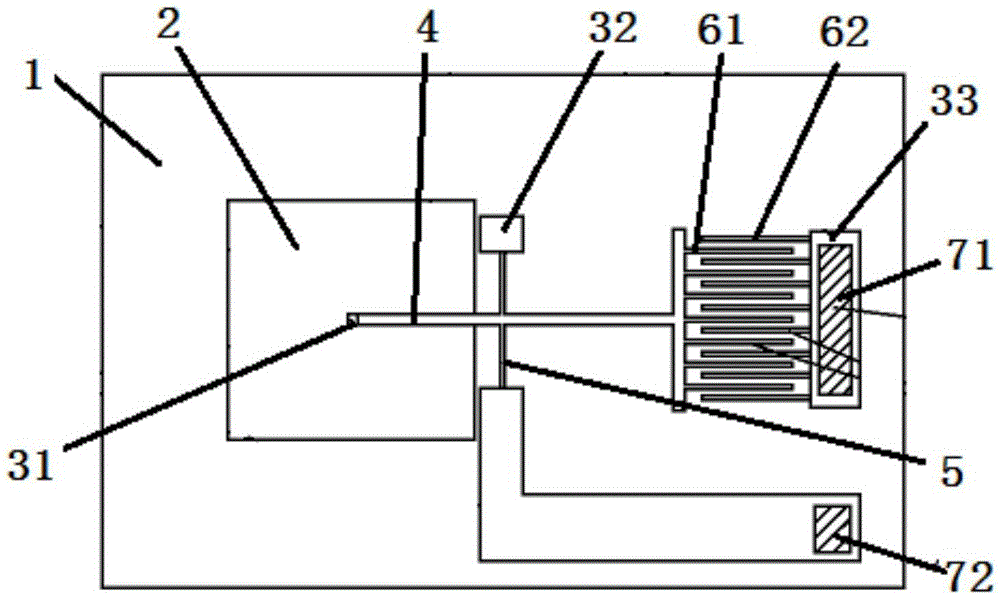

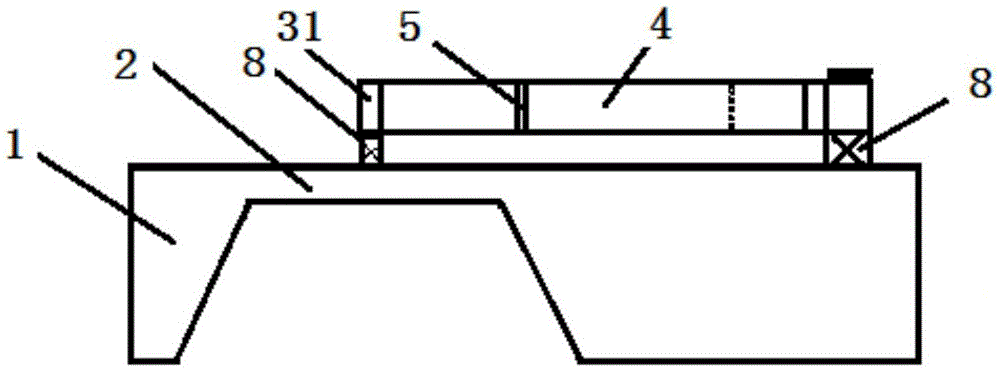

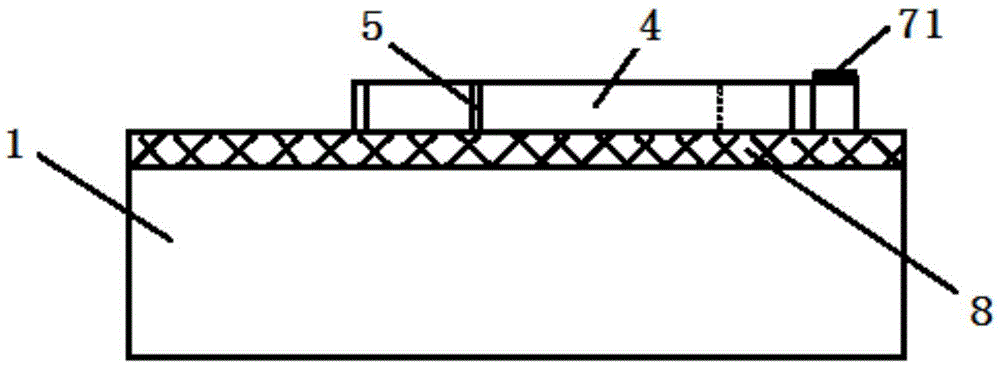

[0026] The high-sensitivity capacitive pressure sensor provided by the present invention comprises a substrate 1, a pressure elastic film 2, a first fixed base 31, a second fixed base 32 and a third fixed base fixed on the substrate 1 respectively 33. Mechanical rod 4, support shaft 5, first interdigitated electrode 61 and second interdigitated electrode 62, first lead electrode 71 and second lead 72, insulating material 8, wherein,

[0027] The substrate 1 is provided with a pressure elastic membrane 2, the central upper surface of the pressure elastic membrane 2 is connected to one end of the first fixed base 31 through an insulating material 8, and the other end of the first fixed base 31 is connected to the end of the mechanical rod 4 One end connection;

[0028] On the surface of the substrate 1, a capacitive structure composed of a first interdigital electrode 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com