An online gas humidification device and method for an industrial furnace

An industrial furnace and gas technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of air mixed into the humidification box, reduce the production efficiency of industrial furnaces, and hidden dangers of sintered product quality, so as to improve production efficiency and ensure sintering quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

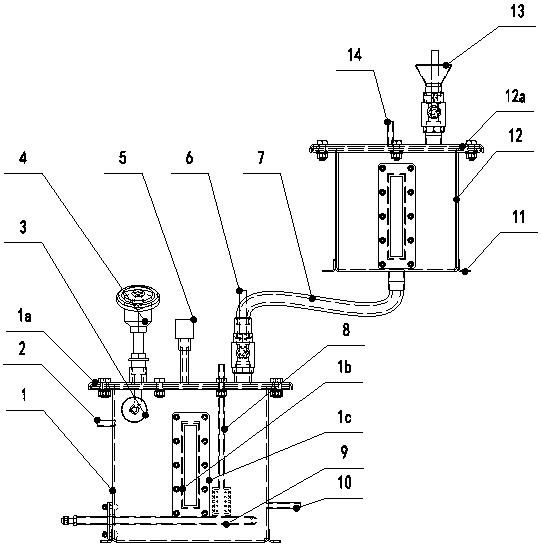

[0023] refer to figure 1 The shown online gas humidifying device for industrial furnaces includes a humidifying box 1 and a water adding box 12 .

[0024] Both the humidifying box 1 and the water adding tank 12 are composed of a box body and an upper cover 1a, 12a connected to the box body through a gasket. One side of the box body is provided with an observation cover 1c and an observation window 1b fitted in the observation cover 1c. A sealing gasket is provided between the observation cover 1c and the box body; through the observation window 1b, the respective liquid levels of the humidification box 1 and the water addition tank 12 can be observed.

[0025] Both the humidifying box 1 and the bottom of the water adding tank 12 are evenly provided with an installation angle seat 11, which is an L-shaped bent plate, which can be fixed on other equipment through the installation hole, and is easy to disassemble.

[0026] The humidification box 1 is equipped with a heating pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com