Condensing resistant method and device of tobacco humidifying duct device

A technology of humidifying device and humidifying tube, which is applied in the field of tobacco, which can solve the problems of high moisture content, shorten storage time, deterioration of tobacco leaves, etc., achieve high-quality humidification, prolong storage time, and prevent tobacco from sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

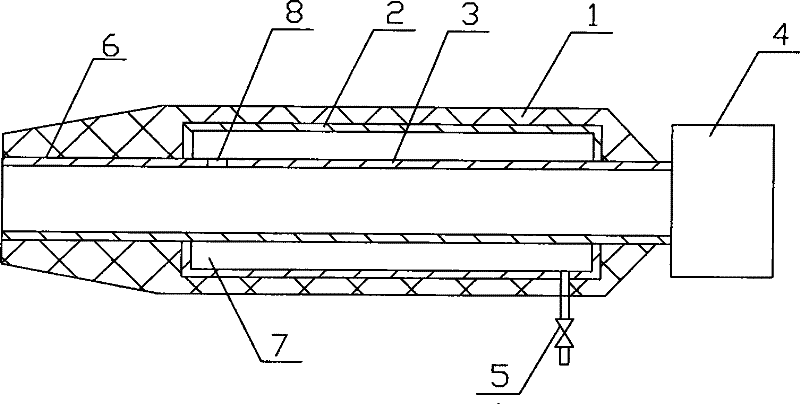

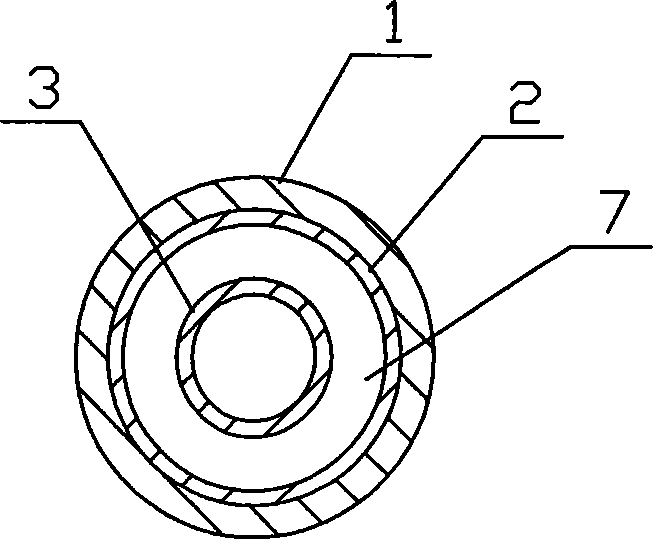

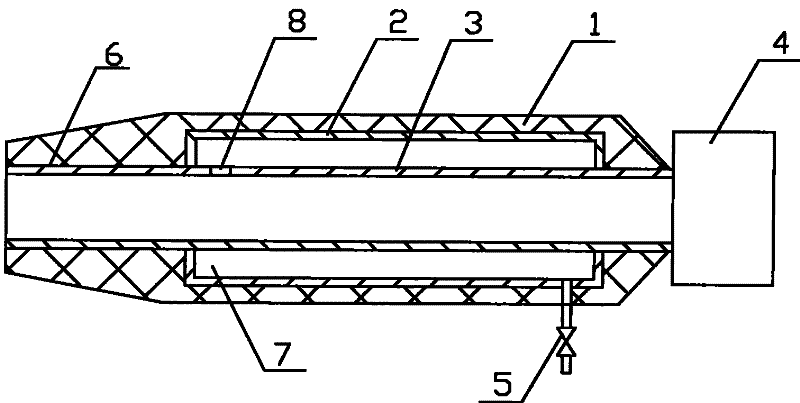

[0016] Such as figure 1 The shown anti-condensation tobacco humidification pipeline device is composed of a delivery pipeline 6 connected to a humidifier 4, and the delivery pipeline 6 close to the humidifier 4 is a jacket structure, and the jacket structure includes an outer sleeve 2 and an inner sleeve 3, Wherein, the inner sleeve 3 communicates with the humidifying device 4, the jacket gap 7 communicates with the inner sleeve 3 through the through hole 8 located at the front end of the inner sleeve 3, and the end of the outer sleeve 2 is provided with a drain valve 5, and the outer sleeve 2 and An insulation layer 1 is arranged outside the conveying pipeline 6 .

[0017] When the anti-condensation tobacco humidification pipeline device is used, the steam is transported into the inner casing 3 and the jacket gap 7 at the same time, and the steam in the inner casing 3 is sent to the humidifying device 4 to directly rehydrate and humidify the tobacco leaves. The steam in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com