A two-stage rotary pyrolysis reactor

A pyrolysis reactor, two-stage technology, used in rotary drum furnaces, special forms of dry distillation, lighting and heating equipment, etc., can solve the problems of thermal efficiency and the difficulty of recycling pyrolysis products, so as to facilitate subsequent processing and ensure quality. , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

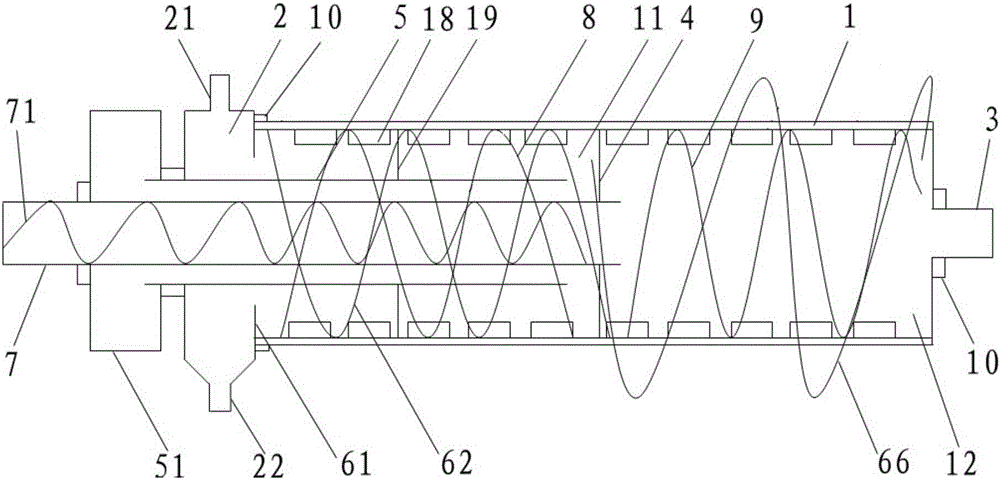

[0026] Such as Figure 1-3 As shown, the two-stage rotary pyrolysis reactor of the present invention includes a cylinder body 1 and a kiln head cover 2, and the kiln head cover 2 is rotatably connected to one end of the cylinder body 1 through a sealing device 10, and the The upper part of the kiln head cover 2 is provided with an exhaust port 21, and the lower part is provided with a slag discharge port 22 for exhaust and slag discharge. The sealing device 10 may be a commonly used sealing device in the field of rotary kiln, such as a scale-type sealing device, to prevent leakage. The above-mentioned structures are well known in the art and will not be repeated here.

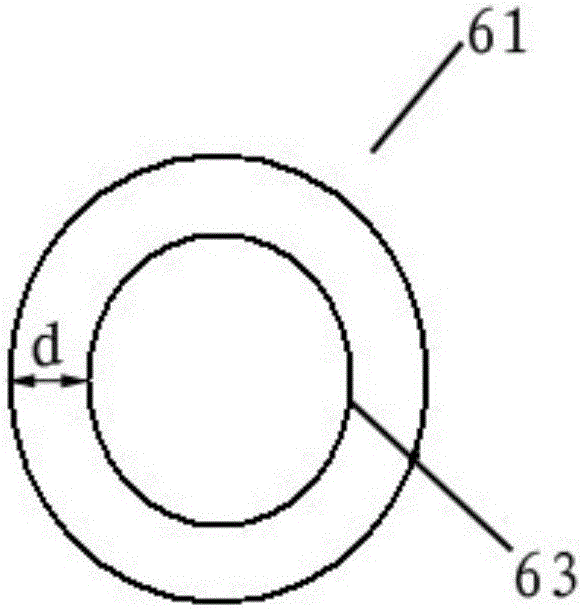

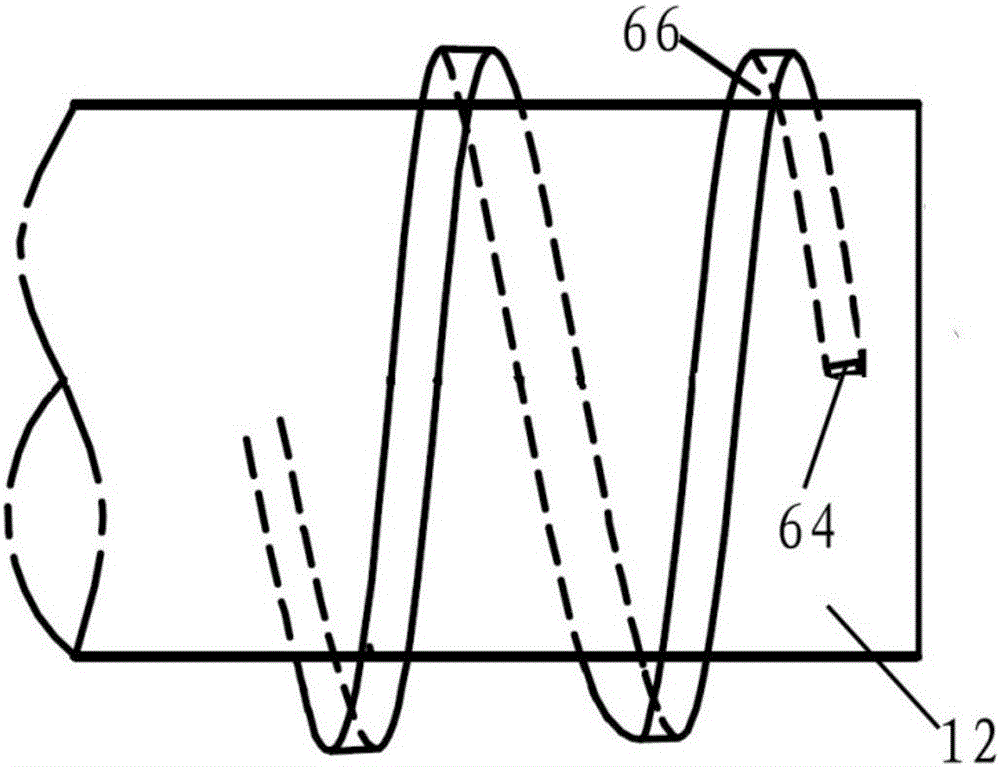

[0027] The pyrolysis reactor also includes a pyrolysis gas outlet 3, a partition 4, an air inlet pipe 5 and a feed pipe 7, and the pyrolysis gas outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com