Continuous drying systems for silica gel production

A drying system and drying technology, which is applied in the direction of static material dryer, drying solid material, drying gas arrangement, etc., can solve the problems of uneven drying degree, high labor intensity of workers, large initial investment, etc., and achieve a controllable drying state , the drying effect is controllable, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

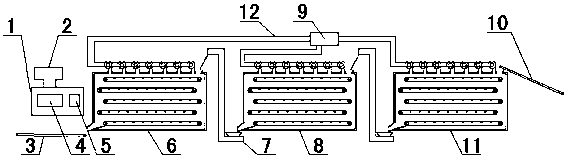

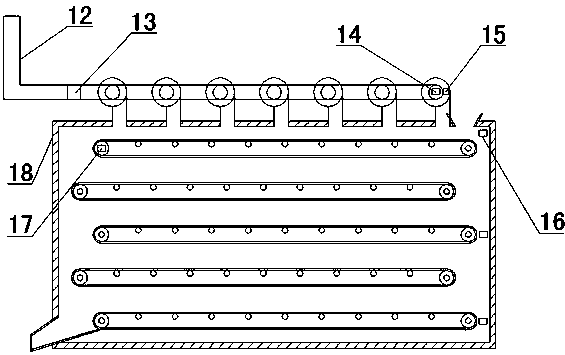

[0022] see figure 1 , figure 2 , the system is composed of the first drying unit 11, the second drying unit 8 and the third drying unit 6 connected in series through the hopper elevator 7, the material enters from the feeding conveyor belt 10, and is output from the discharging conveyor belt 3, each The drying units are all multi-layer belt dryers. The top of the box 18 of each drying unit is respectively equipped with steam pipes 12 connected with the hot air circulation system 9. Fifteen sets of DN40 PN16 dryers are installed at the entrance of the steam pipes 12. Electric cut-off valve 13, the bottom, middle and upper position of the casing 18 inner side of each drying unit are equipped with thermistor 16, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com