A high-efficiency large temperature rise single-stage throttling intercooling heat pump water heater

A heat pump water heater and temperature rise technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of low energy efficiency, large energy consumption, and insufficient working range, so as to improve efficiency, flexible pipelines, and improve The effect of thermodynamic perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

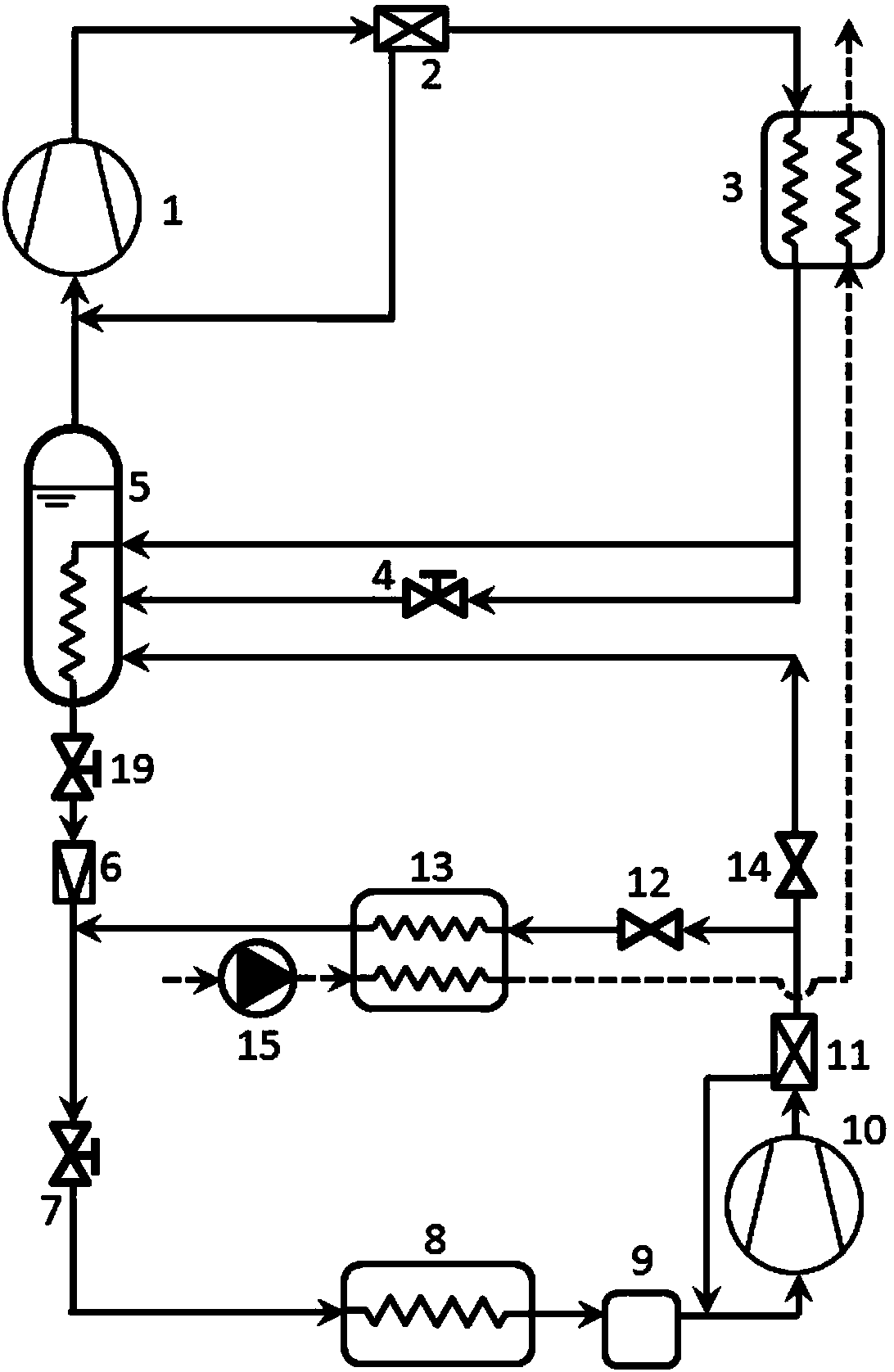

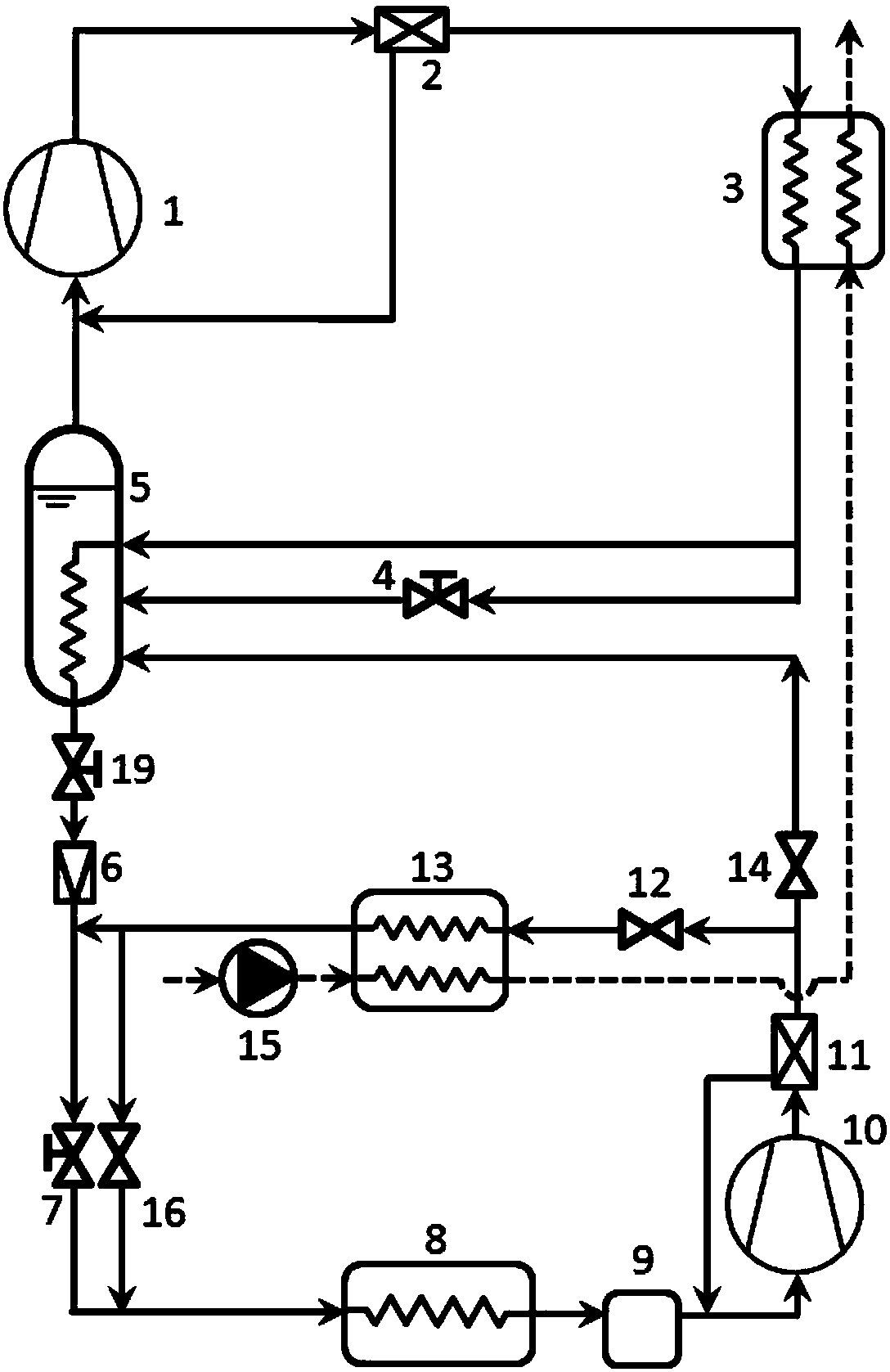

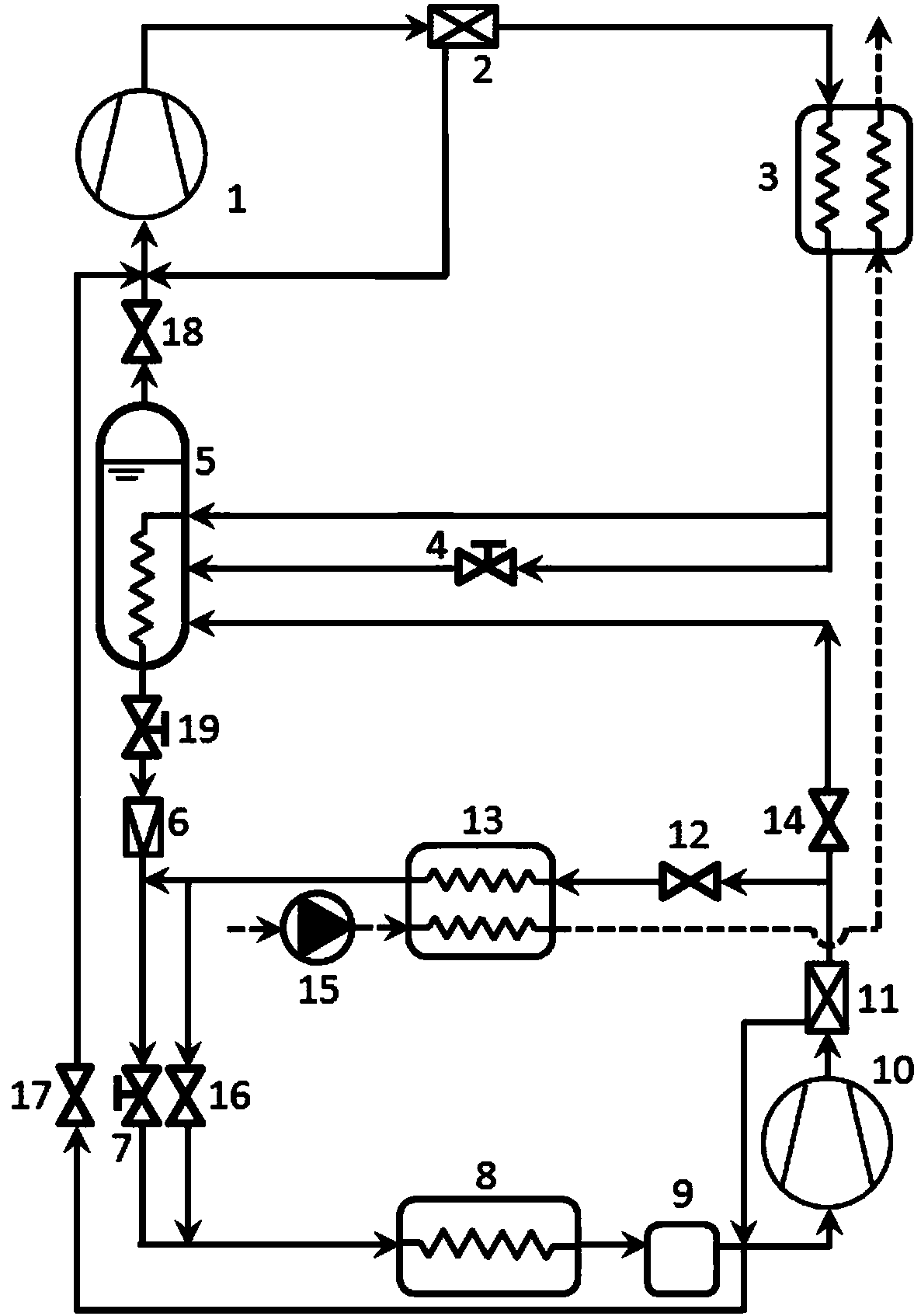

[0020] refer to Figure 1 ~ Figure 3 , a high-efficiency large temperature rise single-stage throttling intercooling heat pump water heater, including a high-pressure compressor 1, a low-pressure compressor 10, a first condenser 3, a second condenser 13, a subcooler 5 and an evaporator 8 , the outlet of the high-pressure compressor 1 communicates with the refrigerant inlet of the first condenser 3, and the outlet of the refrigerant of the first condenser 3 passes through the first throttling device 4 and the subcooler 5 The cooling fluid inlet of the first condenser 3 communicates with the refrigerant outlet of the first condenser 3 and the subcooled liquid inlet of the subcooler 5, and the gas outlet of the subcooler 5 communicates with the high-pressure compressor 1 The inlet of the subcooler 5 is communicated with the inlet of the subcooler 5 through the third thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com