Rotating joint special for ultra-low temperature fluid loading arm

A technology of fluid loading and unloading arms and rotary joints, which is used in fluid handling, equipment loaded into pressure vessels, and installation devices for container structures, etc. , to achieve the effect of increasing nitrogen flow and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

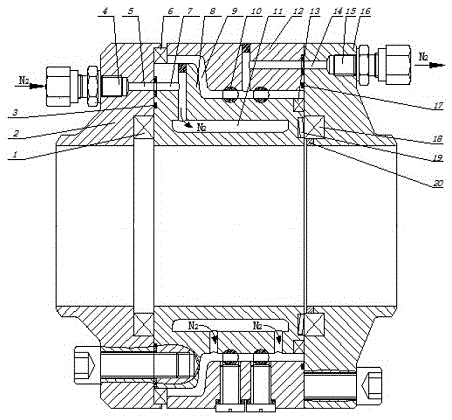

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] As shown in the figure, a special rotary joint for loading and unloading arms of ultra-low temperature fluids includes a left flange 2, a right flange 16, an inner ring 8 and an outer ring 12, the left flange 2 is fixedly connected to the inner ring 8, and the right flange 16 is connected to the inner ring 8. The outer ring 12 is fixedly connected.

[0020] The inner ring 8 is provided with a heat-insulating cavity 11, the main static seal ring 1 and the active seal ring 18 are respectively installed between the inner ring 8 and the left and right flanges, and the outer wall of the inner ring 8 and the inner wall of the outer ring 12 are provided with Nitrogen purge passage 9 is provided with two annular raceways on the nitrogen purge passage 9, and a ball valve 10 that can rotate the inner and outer rings independently around the outer wall of the inner ring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com