Thread ball preventing device for sewing machine

A technology for preventing bird's nests and sewing machines, applied in the field of sewing machines, can solve problems such as deformation of thread hooking devices, disconnection of thread ends, affecting the use of equipment, etc., and achieve the effect of avoiding personal and property losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

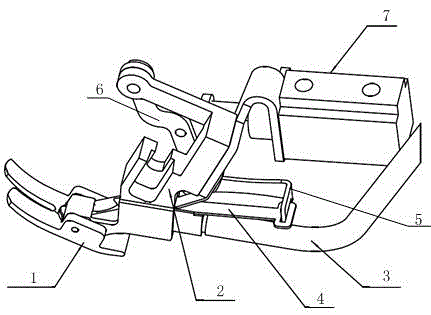

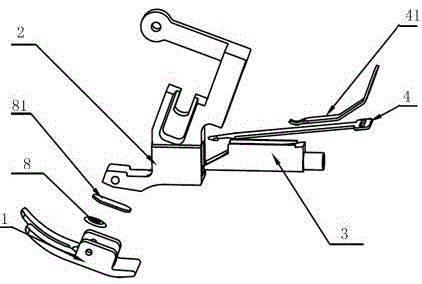

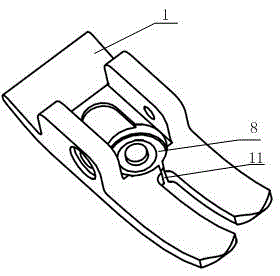

[0013] An anti-bird nest device for a lockstitch sewing machine, comprising a presser foot base plate 1 and a presser foot handle 2 hinged to the presser foot base plate, characterized in that: a hole is arranged on the presser foot handle 2, and a suction pipe 3 and a wire hook 4 are arranged in the hole , wire hook tail end plug wire hook connecting plate 5; one end of the top hinged connecting plate 6 of the presser foot handle, the other end of the connecting plate 6 is hinged to the described line hook connecting plate 5; the presser foot handle is also fixedly connected to the cylinder block of the cylinder 7, the cylinder The piston rod of 7 is hinged with the middle part of the connecting plate 6; a shallow groove is arranged in the middle part of the base plate of the presser foot, and a circular knife 8 is embedded in the shallow groove, and a gap 11 that can accommodate suture penetration is set between the two presser feet of the base plate of the presser foot. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com