A kind of genetically engineered bacteria expressing microbial cholesterol esterase and its construction method

A technology of cholesterol esterase and genetically engineered bacteria, applied in the field of enzyme engineering, can solve the problem that a compatible carrier is not easy to obtain, and achieve the effect of high-efficiency expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the construction of recombinant vector and genetically engineered bacteria

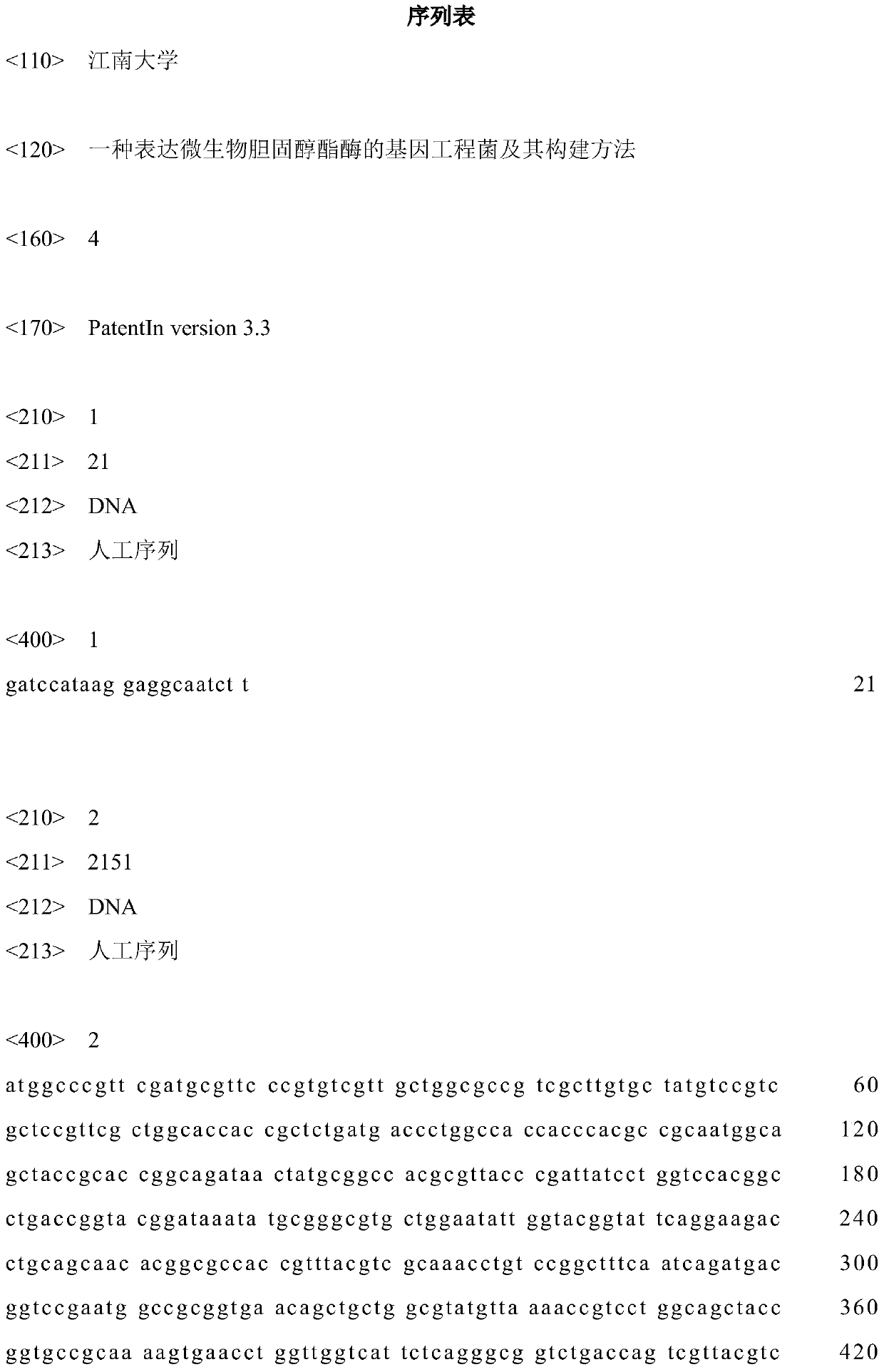

[0024] (1) Cholesterol esterase cheS gene fragment, the sequence of which is GenBank accession number AB175022.1 (cholesterol esterase from Burkholderia cepacia.). The nucleotide sequence of the SD gene fragment is: gatccataaggaggcaatctt. Cholesterol esterase molecular chaperone limS gene fragment, the sequence such as GenBank accession number is AB175022.1 (cholesterol esterase molecular chaperone derived from Burkholderia cepacia.).

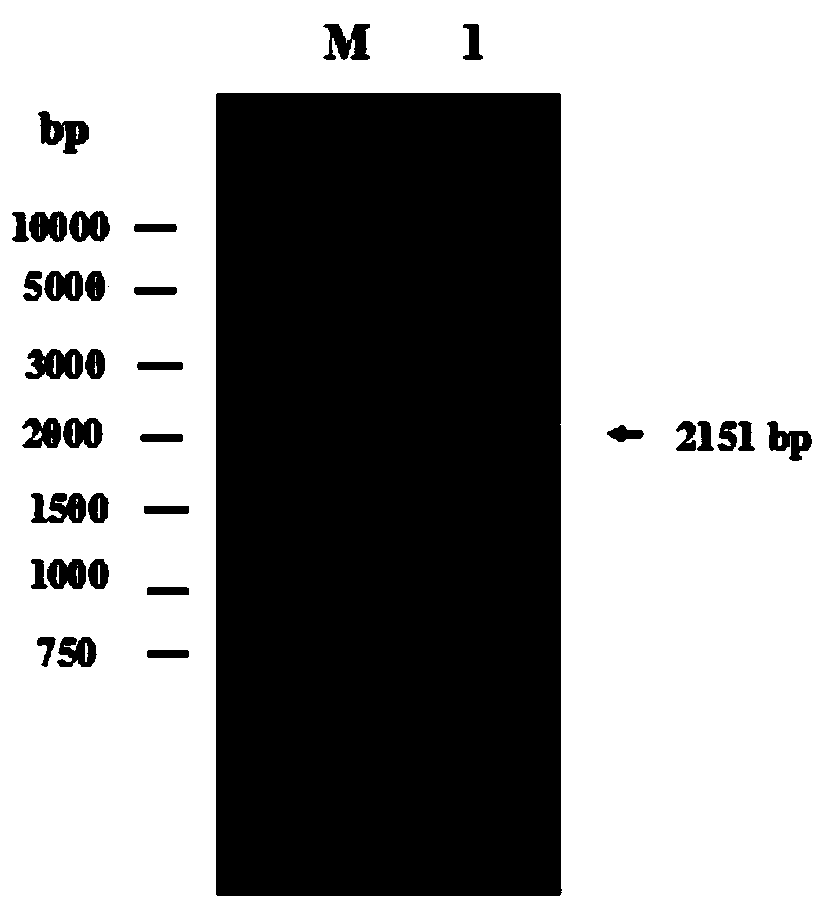

[0025] (2) chemically synthesize the cal gene fragment of the sequence shown in SEQ ID NO.2, or optimize the cheS gene and limS gene in the previous step, and connect them with SD to obtain the fragment of the sequence shown in SEQ ID NO.2.

[0026] (3) PCR was performed using the fragment of the sequence shown in SEQ ID NO.2 as a template, and sequences such as SEQ ID NO.3 and SEQ ID NO.4 as upstream and downstream primers respectively, and the P...

Embodiment 2

[0028] Embodiment 2: Enzyme production by genetic engineering bacteria fermentation

[0029] Preparation of crude enzyme solution

[0030] The culture conditions of the seed liquid: use 250mL shake flask culture, the filling liquid is 20% LB medium, and add filter-sterilized 100mg·mL in the medium -1 Take 50 μL of kanamycin sulfate, take a single colony into the culture medium, and culture overnight at 37°C and 180rpm.

[0031] Fermentation broth culture conditions: use 500mL shake flask culture, the liquid is 20% fermentation medium, the MgSO 4 ·7H 2 O, glucose, and glycerin were made into mother liquors, sterilized separately, and the corresponding amount was added when used, and 100 mg·mL was added for filter sterilization -1 100 μL of kanamycin sulfate was added to 5% seed solution, 37°C, 200rpm, cultured for 8h, added 20% lactose induction solution, 28°C, 200rpm, induced for 20h.

[0032] The collection of bacteria and the acquisition of crude enzyme solution: Centrif...

Embodiment 3

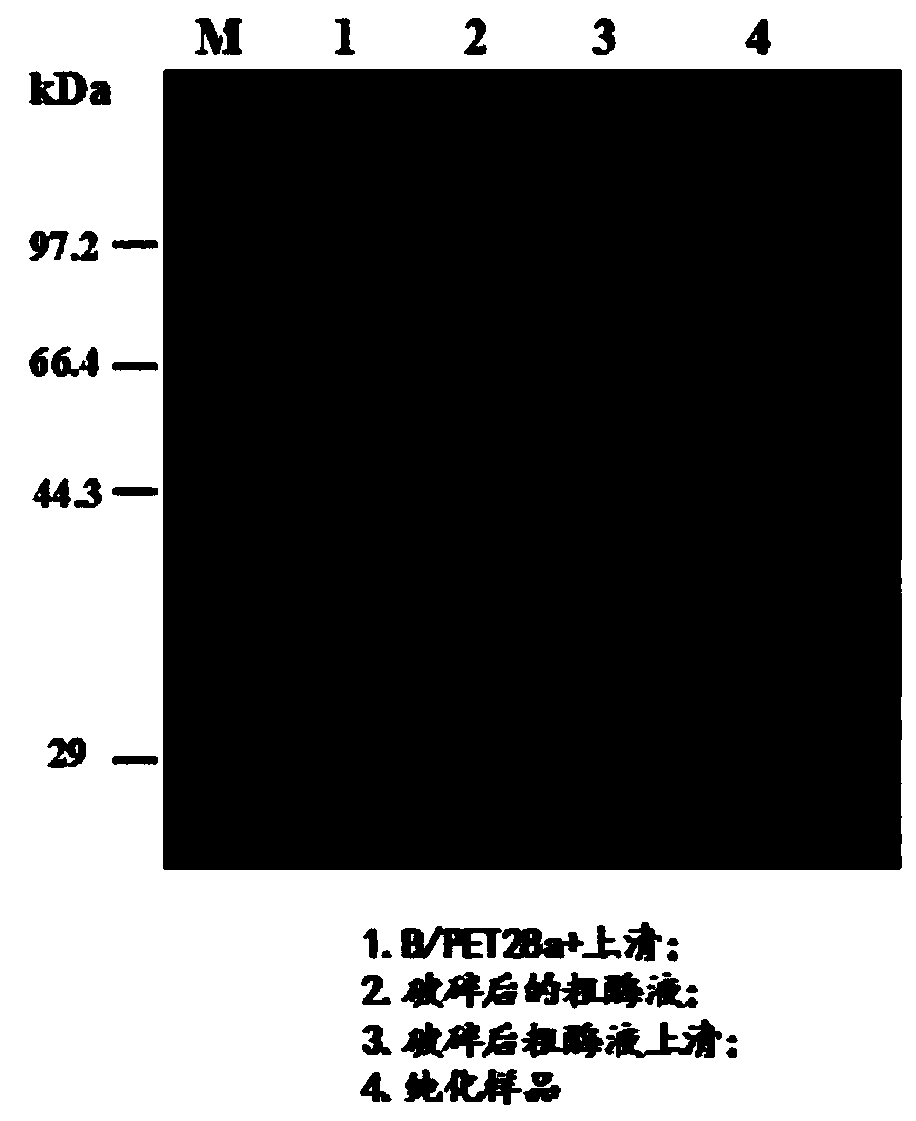

[0036] Example 3: Purification of CAL

[0037] Affinity purification was performed using agarose as matrix, 2-hydroxy-1,3-propanediamine linking arm, and 8-chloroalloxazine as ligand synthesis medium.

[0038] 1. Sample preparation: adjust the conductivity of the loaded crude enzyme solution to be consistent with the conductivity of 0.11M potassium phosphate buffer (pH 7.0).

[0039] 2. Column packing: 15mL plastic small column is fixed vertically, the tube at the lower end of the column is opened, and 3mL of medium is loaded, and allowed to settle, so that the ethanol in the column flows out to about a little higher than the medium interface.

[0040] 3. Equilibration: Equilibrate 10 column volumes with 0.11 M potassium phosphate buffer (pH 7.0).

[0041] 4. Sample loading: Take 20mL of crude enzyme solution and add it to the well-balanced affinity medium.

[0042] 5. Washing: Wash 10 column volumes with 0.11M potassium phosphate buffer (pH 7.0) to remove unbound protein, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com