Wax residue treating method and system

A processing method and technology of a processing system, which are applied in the field of slag wax processing methods and systems, can solve the problems of low economic benefit and waste of organic matter, and achieve the effects of improving economic benefit, avoiding waste and realizing full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

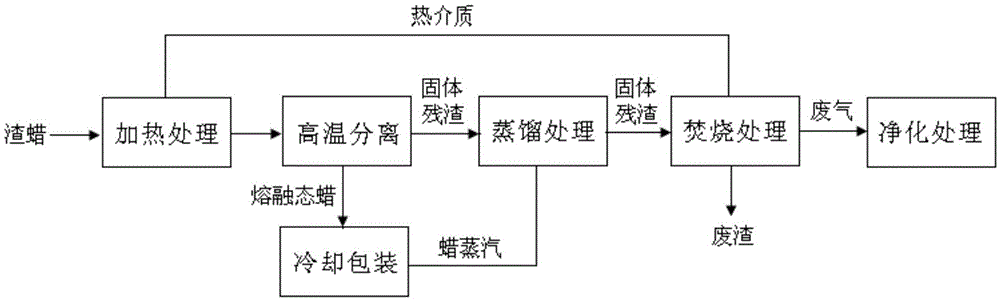

[0030] The treatment object of this embodiment is the slag wax formed by Fischer-Tropsch synthesis, which contains 30-40wt% wax. like figure 1 Shown, slag wax processing method comprises the steps:

[0031] 1. Heat treatment

[0032] Heat the slag wax until the temperature reaches above the melting point of the wax, and keep it warm until the wax in the slag wax is completely melted; wherein, the heating temperature can be 110-160°C.

[0033] 2. High temperature separation

[0034] High-temperature separation of the slag wax after the above heat treatment is carried out to obtain molten wax and solid residue; wherein, before and during the high-temperature separation, the operating temperature is maintained at 110-160°C to keep the wax in a molten state. In addition, the molten wax formed by high-temperature separation can be cooled and packaged to obtain finished wax.

[0035] 3. Incineration treatment

[0036] The solid residue formed by the above high-temperature separ...

Embodiment 2

[0042] like figure 2 As shown, the slag wax processing system of the present embodiment comprises: a melting device 1, which has an inlet and an outlet; a high-temperature separation device 2, which has an inlet, a liquid outlet and a solid outlet, and the inlet of the high-temperature separation device 2 is connected to the melting device through a pipeline 4 The outlet of 1 is connected; the incinerator 3 has an inlet, a solid outlet and a gas outlet, and the inlet of the incinerator 3 is connected to the solid outlet of the high-temperature separation device 2.

[0043]In the above-mentioned slag wax processing system, the melting device 1 is used for heat-treating the slag wax, so as to keep the wax in the slag wax in a molten state. The melting device 1 can be a conventional heating device, such as a partition heat exchanger, which can be heated by means of electric heating, and the heating temperature can be, for example, 110-160°C.

[0044] Before the slag wax flowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com