A kind of preparation method of basalt fiber with through holes

A technology of basalt fiber and basalt, which is applied in the field of basalt fiber preparation, can solve the problems of not being able to prepare basalt fiber with a through-hole structure, and achieve the effects of low production cost, simple production process, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

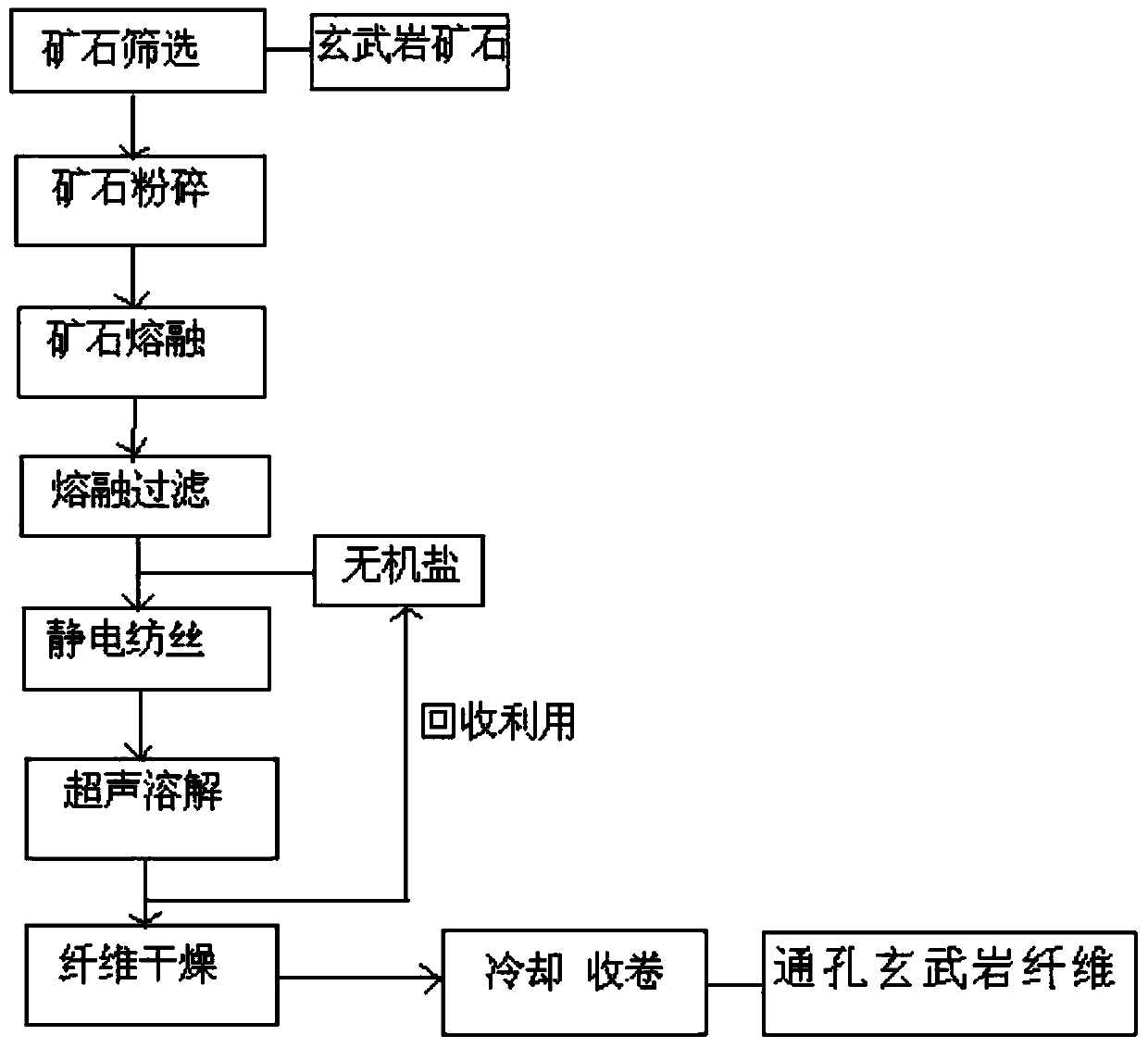

Method used

Image

Examples

Embodiment 1

[0034] 1) Immerse the basalt ore in the pool, wash it, remove the impurities that may be attached to the surface, and then take it out to dry;

[0035] 2) The dried basalt ore obtained in step 1) is crushed with a pulverizer, and the fineness is 2.0 mm, to obtain basalt ore powder;

[0036] 3) Add the basalt powder obtained in step 2) into the kiln, and raise the temperature to 1200°C to melt the basalt powder into a liquid state;

[0037] 4) Filtrating the molten basalt obtained in step 3) at high temperature to remove unmelted basalt powder and impurities;

[0038]5) Introduce the filtered molten basalt obtained in step 4) and the same molten sodium chloride into the coaxial electrospinning machine at the same time, using an outer needle with a diameter of 1.5 mm and an inner needle with a diameter of 0.7 mm. The distance between the inner tip and the outer tip is 0.42mm, and the spinning voltage is 10KV. Coaxial electrospinning is performed to obtain basalt fibrils with a ...

Embodiment 2

[0045] 1) Immerse the basalt ore in the pool, wash it, remove the impurities that may be attached to the surface, and then take it out to dry;

[0046] 2) The dried basalt ore obtained in step 1) is crushed with a pulverizer to obtain basalt ore powder with a fineness of 4.0mm;

[0047] 3) Add the basalt powder obtained in step 2) into the kiln, and raise the temperature to 1550°C to melt the basalt powder into a liquid state;

[0048] 4) Filtrating the molten basalt obtained in step 3) at high temperature to remove unmelted basalt powder and impurities;

[0049] 5) Introduce the filtered molten basalt obtained in step 4) and the same molten potassium chloride into the coaxial electrospinning machine at the same time, using an outer needle with a diameter of 2.5 mm and an inner needle with a diameter of 1.2 mm. The distance between the inner tip and the outer tip is 0.72mm, and the spinning voltage is 15KV. Coaxial electrospinning is performed to obtain basalt fibrils with a ...

Embodiment 3

[0056] 1) Immerse the basalt ore in the pool, wash it, remove the impurities that may be attached to the surface, and then take it out to dry;

[0057] 2) The dried basalt ore obtained in step 1) is crushed with a pulverizer to obtain basalt ore powder with a fineness of 3.0mm;

[0058] 3) Add the basalt powder obtained in step 2) into the kiln, and raise the temperature to 1400°C to melt the basalt powder into a liquid state;

[0059] 4) Filtrating the molten basalt obtained in step 3) at high temperature to remove unmelted basalt powder and impurities;

[0060] 5) Introduce the filtered molten basalt obtained in step 4) and the same molten sodium sulfate into the coaxial electrospinning machine at the same time. A medium-carbon ferrochrome needle with a distance of 0.6mm from the needle tip to the outer needle tip, coaxial electrospinning at a spinning voltage of 13KV to obtain basalt fibrils with a double-layer structure, in which the outer layer is molten basalt and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com