A kind of water body disinfection equipment and method for using it to carry out water body disinfection

A technology for disinfection equipment and water bodies, applied in water/sewage treatment equipment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing human health risks, the treatment efficiency of disinfection technology needs to be improved, etc., to reduce the volume of the reactor , The effect of suppressing the formation of by-products and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

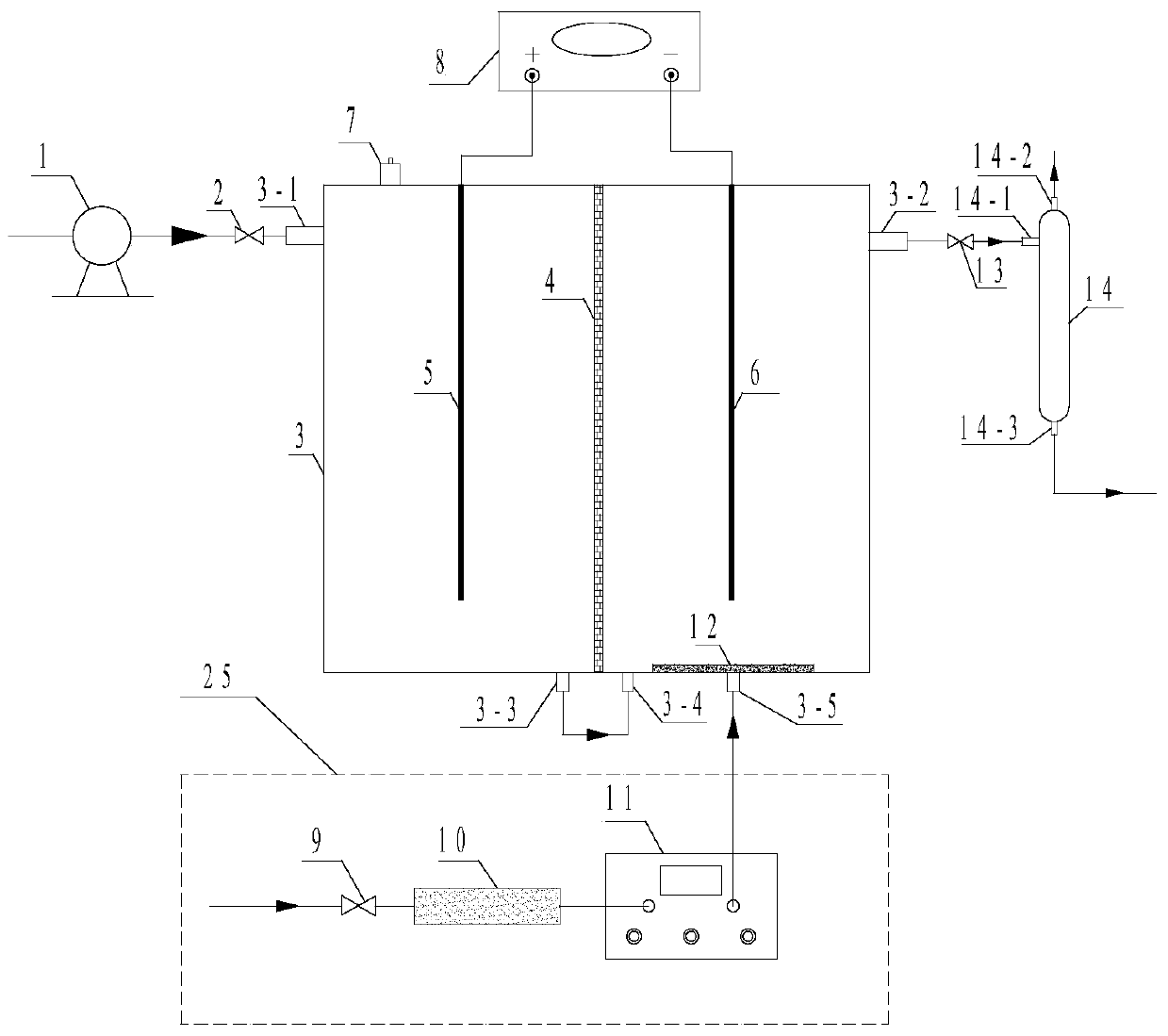

Embodiment 1

[0036] Water disinfection equipment, see figure 1, including water inlet pump 1, No. 1 liquid control valve 2, reaction device 3, diaphragm 4, anode 5, cathode 6, exhaust valve 7, power supply 8, first gas control valve 9, gas dryer 10, ozone generator 11 , ozone aeration device 12, No. 2 liquid control valve 13 and gas-liquid separator 14; No. 1 liquid control valve 2 is located between the water inlet pump 1 and the reaction device 3; The reaction device 3 is provided with a diaphragm 4, and the diaphragm 4 will react The device is divided into an anode chamber and a cathode chamber; the water inlet 3-1 of the anode chamber is connected to the water inlet pump 1, and the water outlet 3-3 of the anode chamber is connected to the water inlet 3-4 of the cathode chamber; the second liquid control valve 13 is located in the reaction device 3 and the gas-liquid separator 14; the cathode chamber water outlet 3-2 is connected to one end of the No. 2 liquid control valve 13, and the ...

Embodiment 2

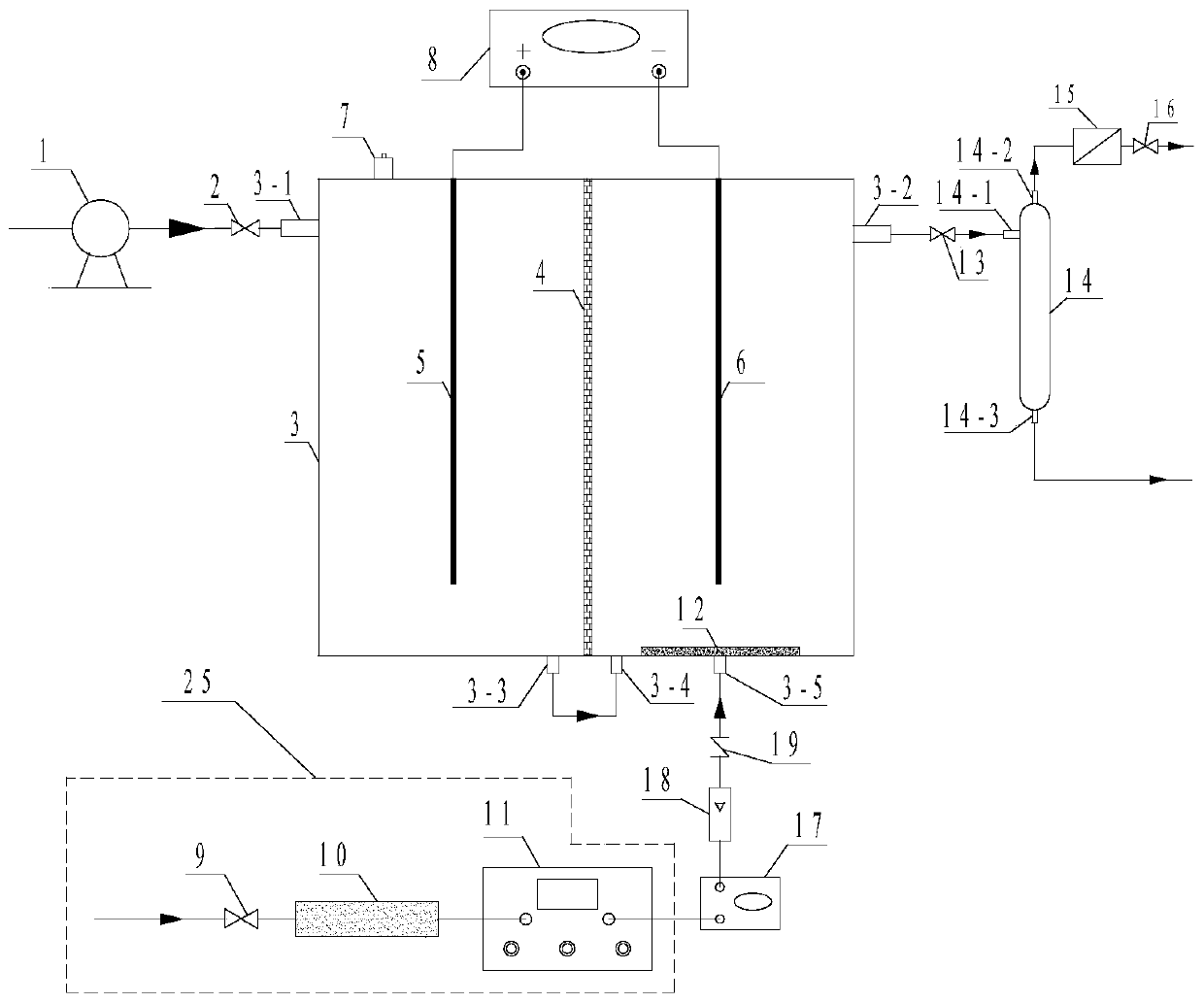

[0040] Water disinfection equipment, see figure 2 , is basically the same as Embodiment 1, except that it also includes an ozone tail gas destroyer 15, a second gas control valve 16, a gas phase ozone concentration monitor 17, a gas flow meter 18 and a check valve 19. The air inlet of the ozone tail gas destroyer 15 is connected with the gas-liquid separator gas outlet 14-2, and the gas outlet of the ozone tail gas destroyer 15 is connected with the second gas control valve 16; the ozone generator 11, the gas phase ozone concentration monitor 17, the gas flow rate The meter 18 and the check valve 19 are connected sequentially; the check valve 19 is connected with the ozone aeration device 12 through the cathode chamber air inlet 3-5.

[0041] The ozone tail gas destroyer 15 can remove the residual ozone gas in the tail gas after gas-liquid separation to ensure safety and environmental protection; the gas phase ozone concentration monitor 17 and the gas flow meter 18 can reali...

Embodiment 3

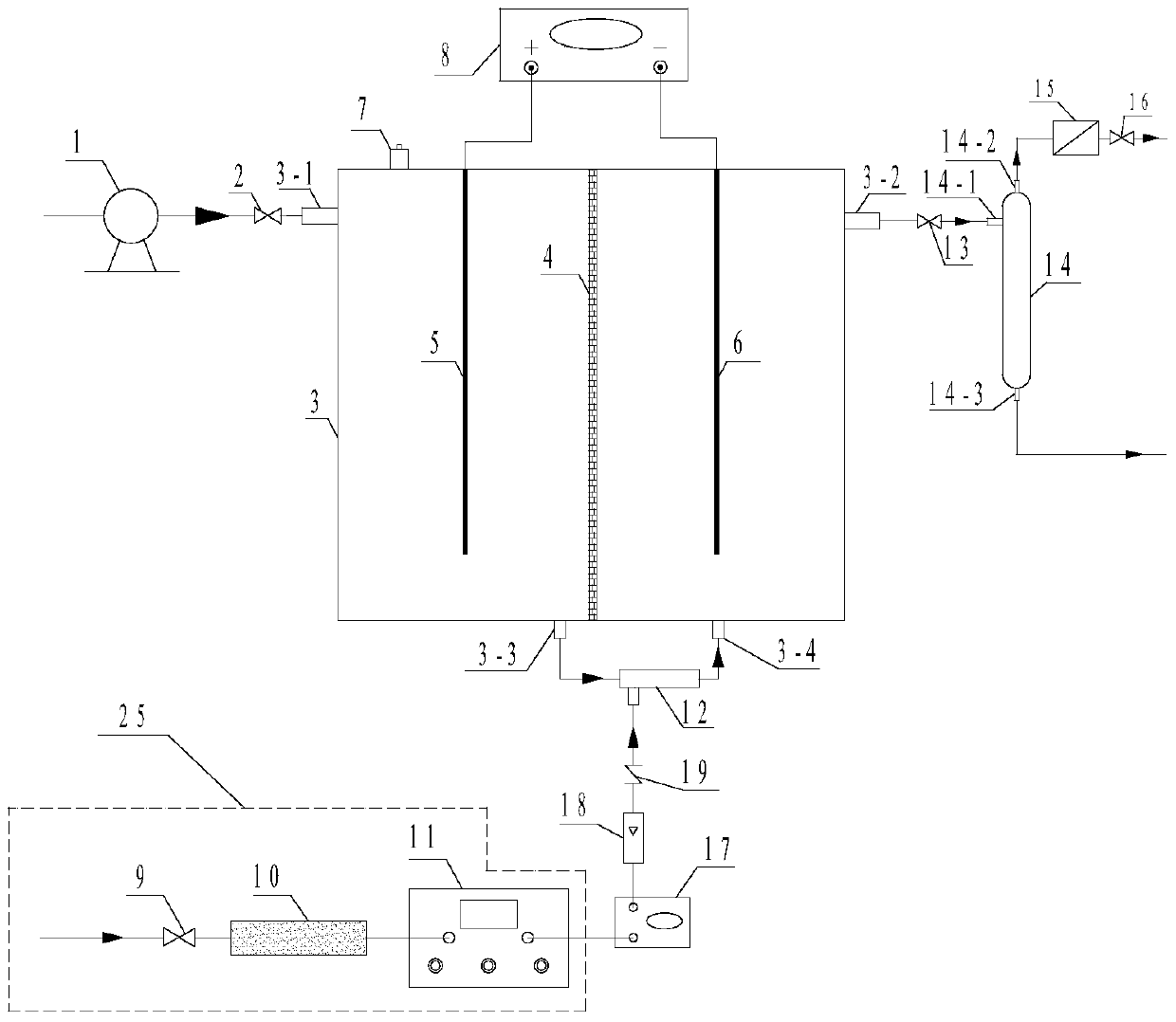

[0043] Water disinfection equipment, see image 3 , is basically the same as Example 2, the only difference is that the ozone aeration device 12 is a hydraulic jet, a pipeline gas-liquid mixer, a gas-liquid mixing pump, etc. placed outside the reaction device 3, and is located at the anode chamber water outlet 3 -3 and the cathode chamber water inlet 3-4, and communicate with the ozone generating device 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com