Synthetic fiberboard moisture and mildew prevention treatment technology

A man-made fiber and processing technology, applied in the field of moisture-proof and mildew-proof, man-made fiber moisture-proof and mildew-proof, can solve the problems of high operating cost, unreachable in ordinary places, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The treatment process provided in this embodiment includes the following steps: (1), the sodium silicate crystal Na 2 O.nSiO 2 And sodium fluorosilicate crystals to make a density of 1.35g / cm 3 The solution, n is 2.6. And mix the sodium silicate solution and sodium fluorosilicate solution uniformly according to the mass ratio of 2:1 and place them for more than 24 hours, and then put the mixed solution into the container;

[0018] (2) The mixed solution is coated on the surface of the man-made fiberboard by pressure spraying method to complete the moisture-proof and mildew-proof treatment process;

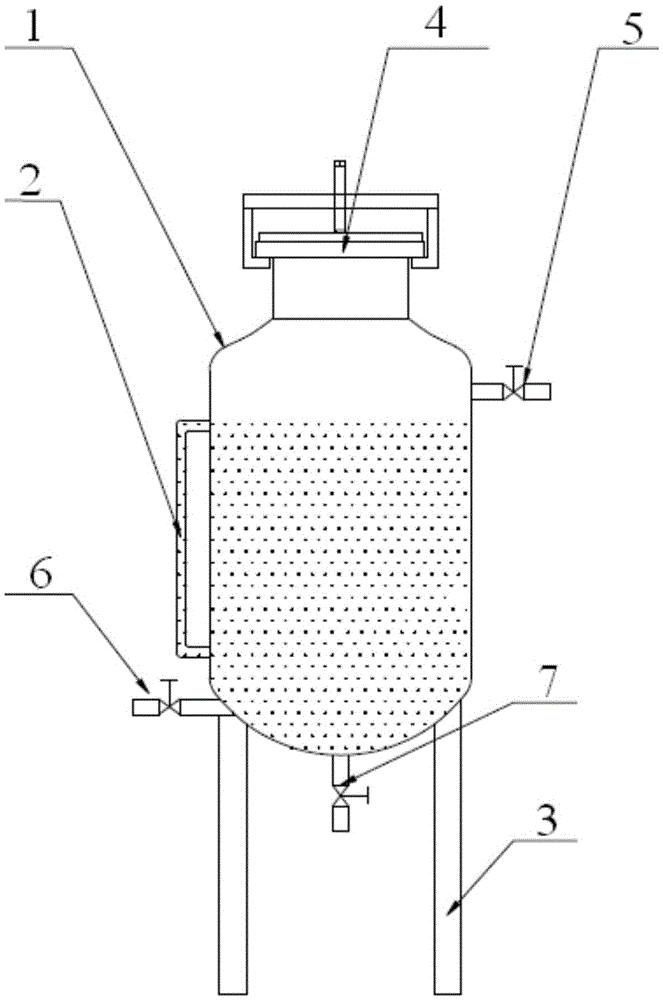

[0019] The described pressure spraying method is: transfer the configured mixed solution into the air pressure spraying storage container, the storage volume is less than 4 / 5 of the container volume, and spray the mixed solution under the action of atomizable air pressure On the surface of the rayon board, after the first spray is air-dried for more than 2 hours, confirm that the...

Embodiment 2

[0023] The treatment process provided in this embodiment includes the following steps: (1), the sodium silicate crystal Na 2 O.nSiO 2 And sodium fluorosilicate crystals to make a density of 1.35g / cm 3 The solution, n is 4.5. And mix the sodium silicate solution and the sodium fluorosilicate solution uniformly according to the mass ratio of 1:95 and place them for more than 24 hours, and then put the mixed solution into the container;

[0024] (2) Coating the mixed solution on the surface of the man-made fiberboard by the method of full intrusion in the container to complete the moisture-proof and mould-proof treatment process;

[0025] The method of full penetration in the container is: pour the mixed solution into the container, put the rayon board to be processed into the solution, immerse all the rayon board, and let the mixed solution fully penetrate the rayon board to ensure the rayon board A protective film is formed on the shallow layer. After 2 minutes of infiltration, the ...

Embodiment 3

[0028] The treatment process provided in this embodiment includes the following steps: (1), the sodium silicate crystal Na 2 O.nSiO 2 And sodium fluorosilicate crystals to make a density of 1.35g / cm 3 The solution, n is 1.5. And mix the sodium silicate solution and the sodium fluorosilicate solution uniformly according to the mass ratio of 95:1 and place them for more than 24 hours, and then put the mixed solution into the container;

[0029] (2) Coating the mixed solution on the surface of the man-made fiberboard by the method of full intrusion in the container to complete the moisture-proof and mould-proof treatment process;

[0030] The method of full penetration in the container is: pour the mixed solution into the container, put the rayon board to be processed into the solution, immerse all the rayon board, and let the mixed solution fully penetrate the rayon board to ensure the rayon board A protective film is formed on the shallow layer. After 2 minutes of infiltration, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com