Full-automatic steering welding equipment

A welding equipment and fully automatic technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high welding technical requirements, unstable product quality, missing welding, etc., to achieve full welding parts without defects, welding quality Stable and reliable, fully automated and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

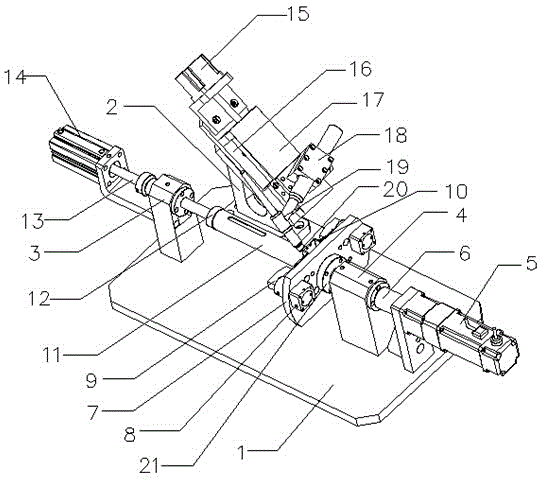

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as Figure 1-3 As shown in , a fully automatic steering welding equipment includes a base 1, a welding torch base 2 is provided on one side of the base 1, a welding torch cylinder 15 and a slide rail 16 are provided on the welding torch base 2, and a slide block 17 is provided on the slide rail 16. The front end of slide block 17 is provided with rotating block 18, and welding torch support 19 is housed in the rotating block 18, and welding torch support 19 is provided with welding torch 20, and rear positioning seat 3 and front positioning seat 4 are respectively provided at base 2 two ends, rear positioning seat 3 The outside is provided with a positioning cylinder 14, the positioning cylinder 14 is connected with the fixed shaft 13, the fixed shaft 13 is located in the rear positioning seat 3, the other end of the fixed shaft 13 is installed with the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com