Automotive lamp lens welding device

A welding device and lens technology, which is applied to other household appliances, optical components, household appliances, etc., can solve problems such as high mechanical structure requirements, stress deformation, and complex linkage control, etc., to achieve flexible control, high degree of automation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

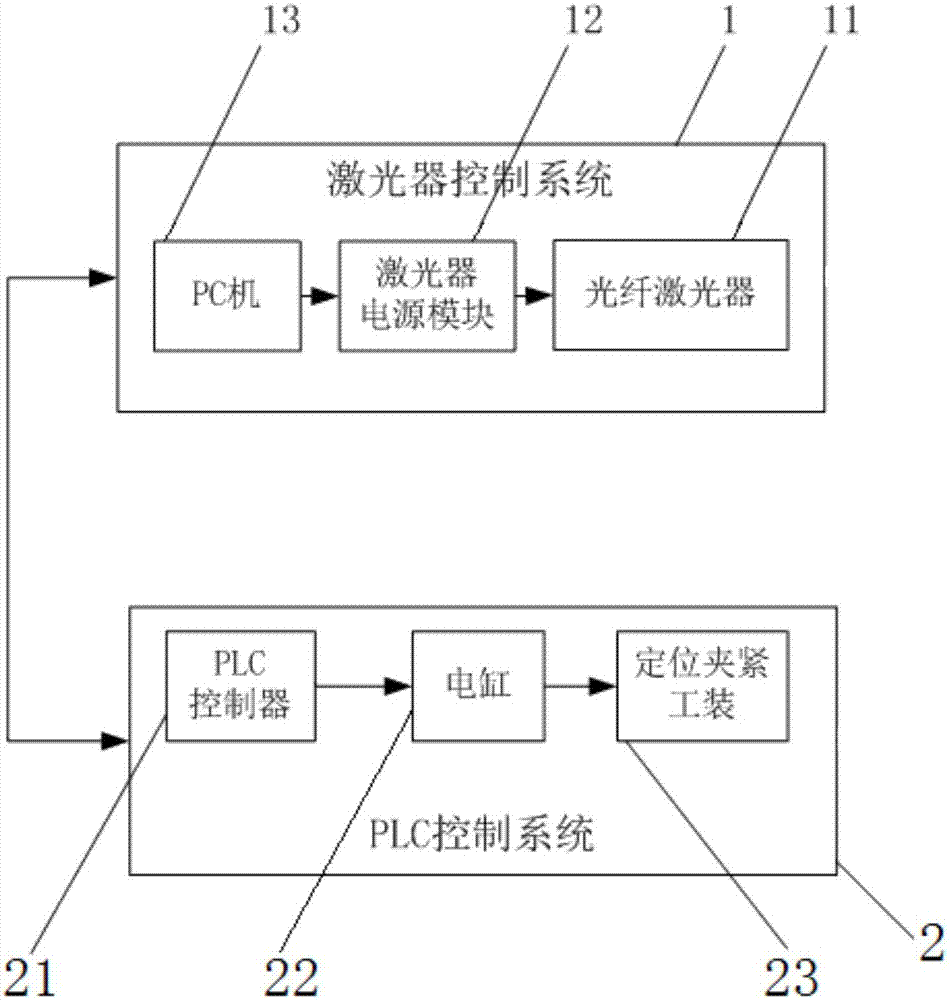

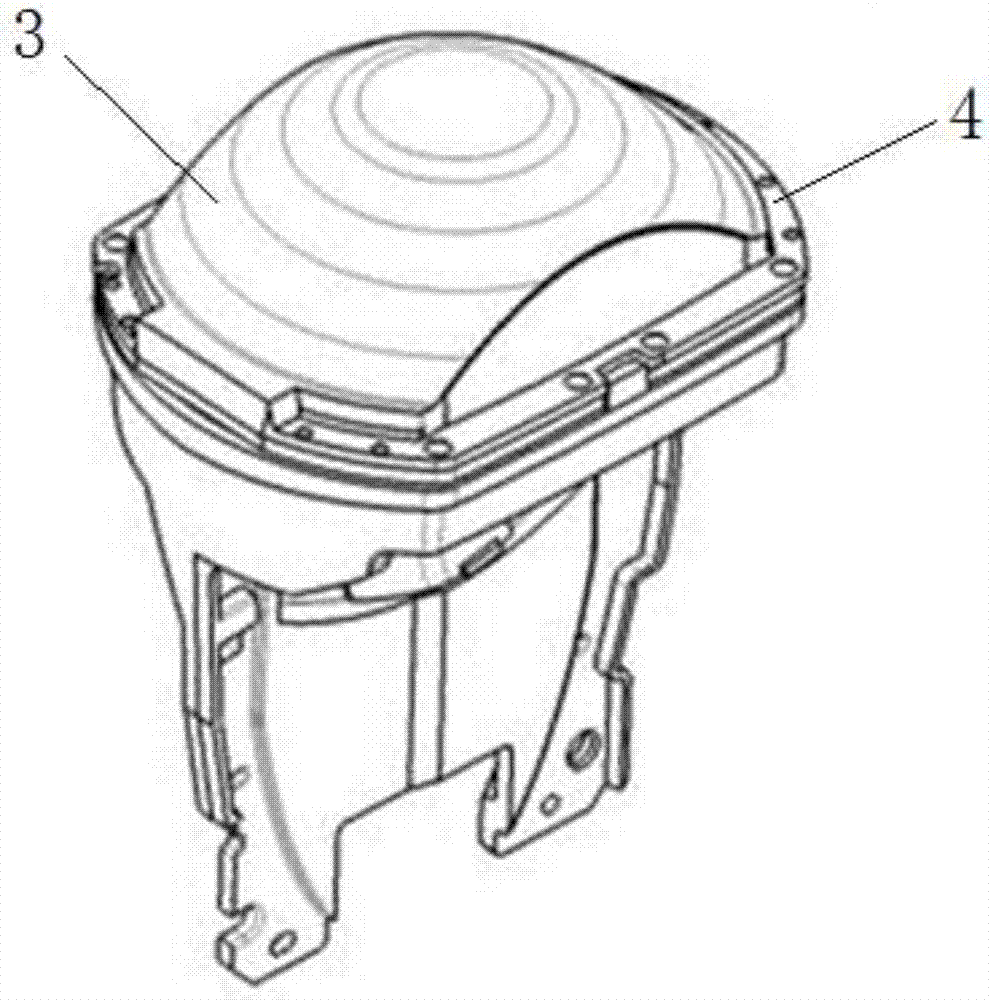

[0017] like figure 1 and 2 As shown, the present invention discloses a welding device for a vehicle lamp lens, comprising a laser control system 1 and a PLC control system 2, the laser control system 1 comprising a fiber laser 11, a laser power supply module 12 and a PC 13, the PC 13 and the laser The power supply module 12 is connected, the laser power supply module 12 is connected with the fiber laser 11, and the PC 13 is used to set the current and power consumption of the fiber laser 11 working output; the PLC control system 2 includes a PLC controller 21, an electric cylinder 22 and a positioning The clamping tool 23 and the PLC controller 21 are used to drive the electric cylinder 22 , and the electric cylinder 22 enables the positioning and clamping tool 23 to closely contact the lens 3 and the bracket 4 ; the PC 13 is connected to the PLC controller 21 . Wherein, the material of the lens 3 is PMMA, which has a high light transmittance, and the bracket 4 is made of PC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com