Automatic welding device of ball joint handrail

An automatic welding and ball joint railing technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable welding quality and low efficiency of manual welding of circular seams, and achieve low manufacturing cost and high welding efficiency. Stable and reliable quality, the effect of enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

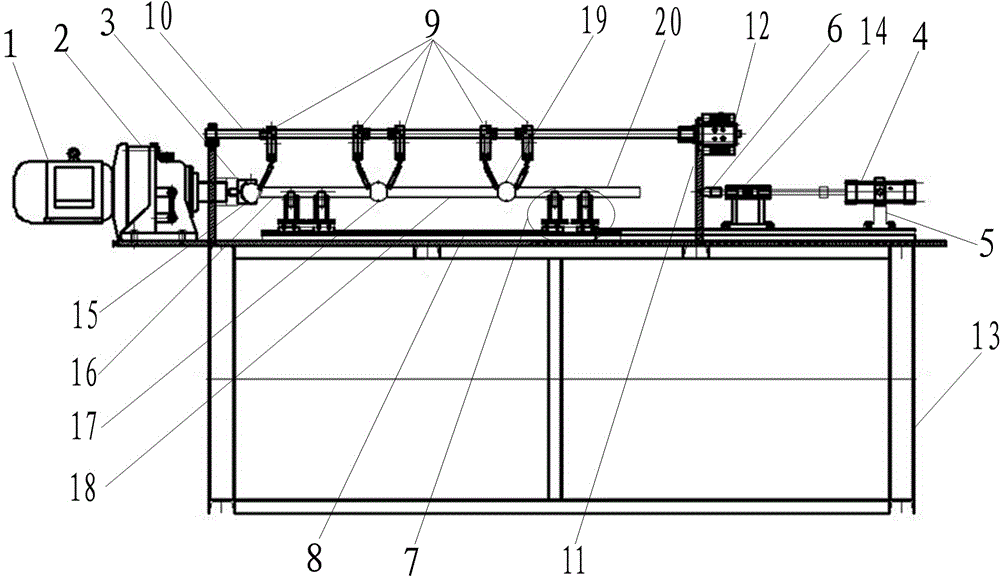

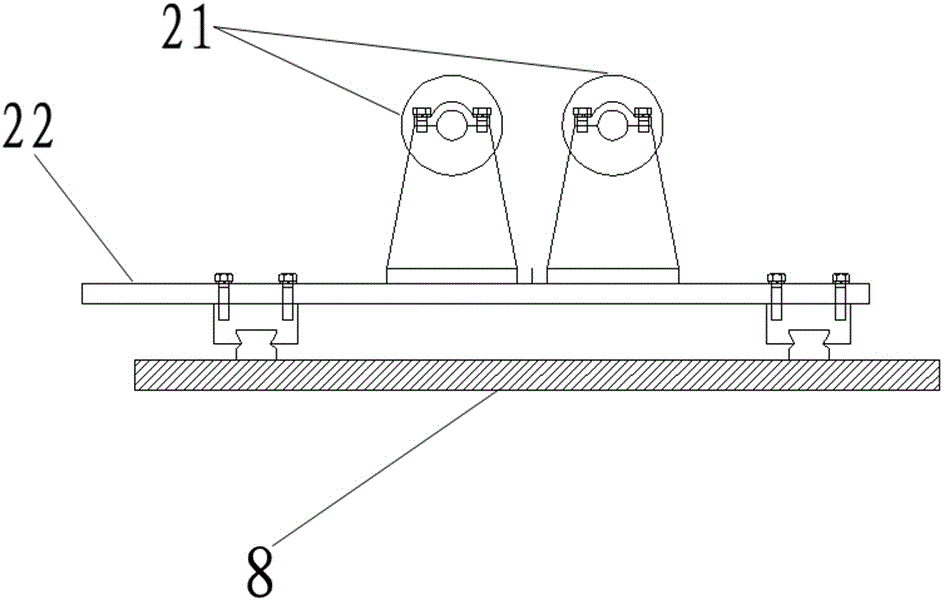

[0015] An automatic welding equipment for ball joint railings, comprising a bed 13, a welding machine, a welding torch 9 connected to the welding machine, a power rotating mechanism installed above the bed 13, and the power rotating mechanism includes a motor 1 and a The reducer 2 is characterized in that: the opposite side of the power rotation mechanism is provided with a locking mechanism installed on the bed 13, and the locking mechanism includes a telescopic power push rod 4, and the base of the power push rod 4 adopts Bolts are installed on the upper panel of the first support frame 5, and the base of the first support frame 5 is installed in the long slotted hole on the bed 13 by bolts; the front end of the push rod is provided with a locator 6 that can rotate with the connecting rod, so One end of the locator 6 is welded to the push rod, and the other end is a rotatable wedge block; a slidable bracket 7 is arranged between the locking mechanism and the power rotation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com