RTV coating spraying equipment for supporting column insulator of transformer substation

A technology for post insulators and spraying equipment, applied in coatings, spray booths, spraying devices, etc., can solve problems such as inability to ensure uniform coating thickness, difficult to guarantee coating quality, and unsafe construction personnel, so as to improve RTV coating The effect of layer quality, low manufacturing cost, and improved spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

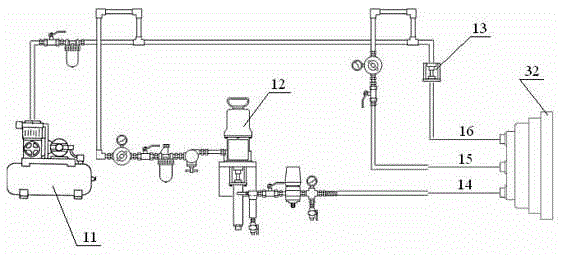

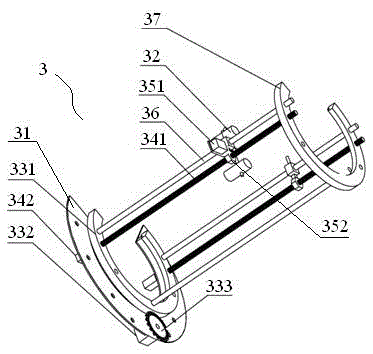

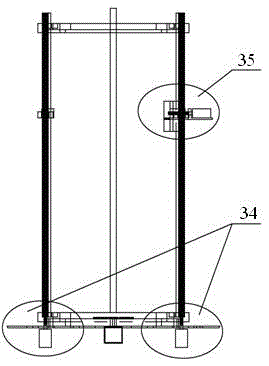

[0024] A substation post insulator RTV paint spraying equipment, its structure is as follows Figure 1 to Figure 5 As shown, it includes a spraying pressure system 1 and a spraying device with a spray gun 32 , and the spraying device completes the spraying operation of substation post insulators under the control of the spraying pressure system 1 .

[0025] The structure of the spraying pressure system 1 is as follows: figure 1 As shown, an air compressor 11 , a storage tank 12 , a spray pump and a controller 13 are included. The air compressor 11 communicates with the spray gun 32 through the air supply pipeline 15; the storage tank 12 communicates with the spray gun 32 through the paint pipeline 14, and the spray pump is arranged in the paint pipeline 14; The controller 13 is also respectively connected with the air compressor 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com