Graphene composite and preparation method thereof

A composite material and graphene technology, applied in the field of graphene, can solve the problems of high energy consumption and difficult process, and achieve the effects of low energy consumption, simple process and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

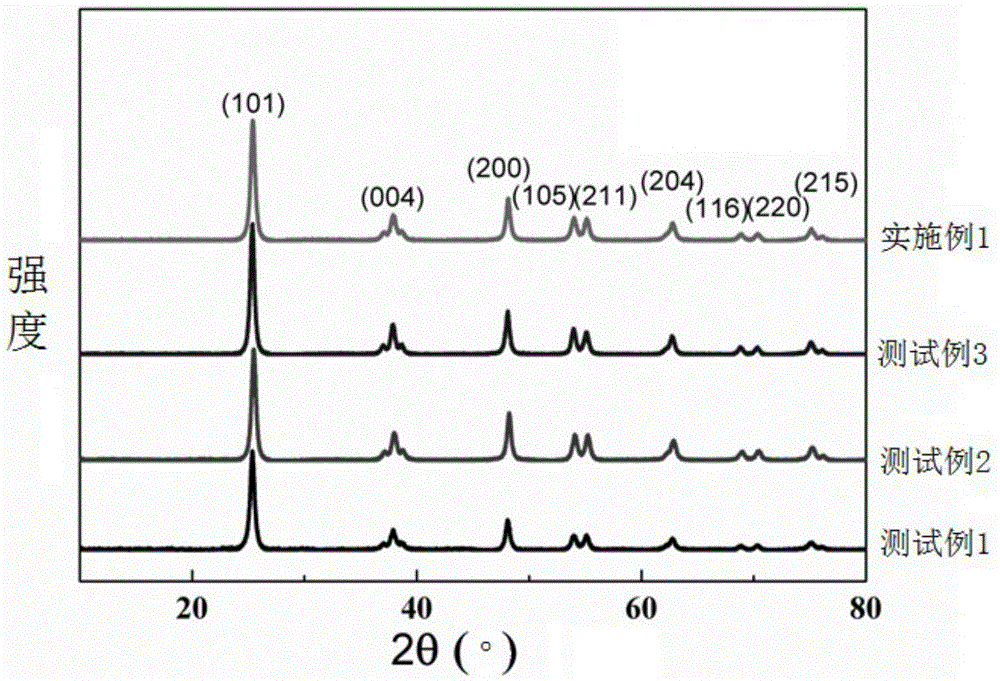

Embodiment 1

[0041] The present embodiment provides a kind of preparation method of graphene composite material, comprises the steps:

[0042] S1, preparing titanium dioxide nanowires;

[0043] Specifically:

[0044] S11. Configure 45ml of an aqueous solution of 15mol / L sodium hydroxide, add 480mg of titanium dioxide P25, and mix evenly to prepare a mixed solution A;

[0045] S12. Put the mixed solution A in a hydrothermal reactor with a volume of 100ml and a polytetrafluoroethylene liner, and react at 180°C for 48 hours to obtain the mixed solution B;

[0046] S13, centrifuging and washing the mixed solution B until the eluate is neutral to obtain a precipitate A;

[0047] S14. Perform hydrogen ion exchange on the precipitate A, centrifuge and wash until the eluate is neutral, and obtain precipitate B after drying; the hydrogen ion exchange step is: place the precipitate A at a concentration of 0.2 mol / L of nitric acid aqueous solution, stirred slowly for 12 hours, repeated 1-3 times....

Embodiment 2

[0053] The present embodiment provides a kind of preparation method of graphene composite material, comprises the steps:

[0054] S1, preparing titanium dioxide nanowires;

[0055] Specifically:

[0056] S11. Configure 45ml of an aqueous solution of 10mol / L sodium hydroxide, add 360mg of titanium dioxide P25, and mix evenly to prepare a mixed solution A;

[0057] S12. Put the mixed solution A in a polytetrafluoroethylene-lined hydrothermal reactor, and react at 150° C. for 72 hours to obtain the mixed solution B;

[0058] S13, centrifuging and washing the mixed solution B until the eluate is neutral to obtain a precipitate A;

[0059] S14. Perform hydrogen ion exchange on the precipitate A, centrifuge and wash until the eluate is neutral, and obtain precipitate B after drying; the hydrogen ion exchange step is: place the precipitate A at a concentration of 0.5 mol / L of nitric acid aqueous solution, stirred slowly for 12 hours, repeated 2 times.

[0060] S15. Calcining the p...

Embodiment 3

[0064] The present embodiment provides a kind of preparation method of graphene composite material, comprises the steps:

[0065] S1, preparing titanium dioxide nanowires;

[0066] Specifically:

[0067] S11. Configure 45ml of an aqueous solution of 10mol / L sodium hydroxide, add 3.6g of titanium dioxide P25, and mix evenly to prepare a mixed solution A;

[0068] S12. Put the mixed solution A in a polytetrafluoroethylene-lined hydrothermal reaction kettle, and react at 220° C. for 12 hours to obtain the mixed solution B;

[0069] S13, centrifuging and washing the mixed solution B until the eluate is neutral to obtain a precipitate A;

[0070] S14. Perform hydrogen ion exchange on the precipitate A, centrifuge and wash until the eluate is neutral, and obtain precipitate B after drying; the hydrogen ion exchange step is: place the precipitate A at a concentration of 0.1 mol / L of nitric acid aqueous solution, stirred slowly for 12 hours, repeated 3 times.

[0071] S15. Calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com