Method for improving sandy soil without tillage with straw in cooperation with biochar

A biochar and straw technology, which is applied in the fields of land preparation methods, applications, agricultural machinery and implements, to achieve the effects of increasing crop yield, improving soil bulk density, and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

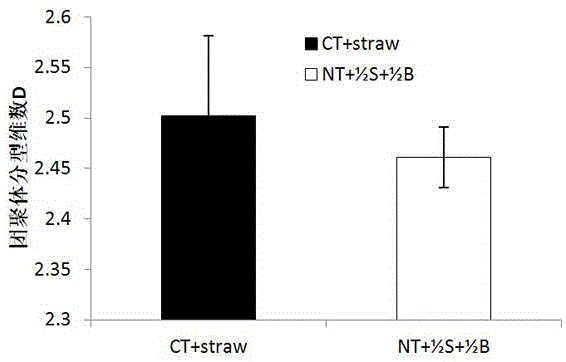

Image

Examples

Embodiment

[0027] In this example (NT+1 / 2B+1 / 2S), the method of no-tillage improvement of sandy fluvo-aquic soil with straw and biochar, the steps are as follows:

[0028] (1) After the corn is harvested, half of the corn stalks are removed, and half of the corn stalks are cut into 4-6cm pieces to obtain corn stalks. Use a ditch opener to directly open a 5cm deep small ditch to sow wheat, and then spread the corn stalks evenly Biochar with the same amount of carbon as crushed corn stalks and crushed corn stalks;

[0029] (2) After the wheat is harvested, half of the wheat straw is removed, half of the wheat straw is cut into 4-6cm pieces to obtain wheat straw, and then evenly spread biochar with the same amount of carbon as wheat straw and wheat straw, and sow sow corn directly;

[0030] (3) Repeat steps (1) and (2) three times.

[0031] It has been carried out at the North China Wheat and Corn Rotation Experimental Station in the Airport District of Xinzheng City, Henan Province since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com