Method for producing a steel component having a metal coating protecting it against corrosion, and steel component

A technology for anti-corrosion protection and steel components, applied in metal layered products, metal material coating processes, manufacturing tools, etc., can solve problems such as cost, reduce hydrogen absorption, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

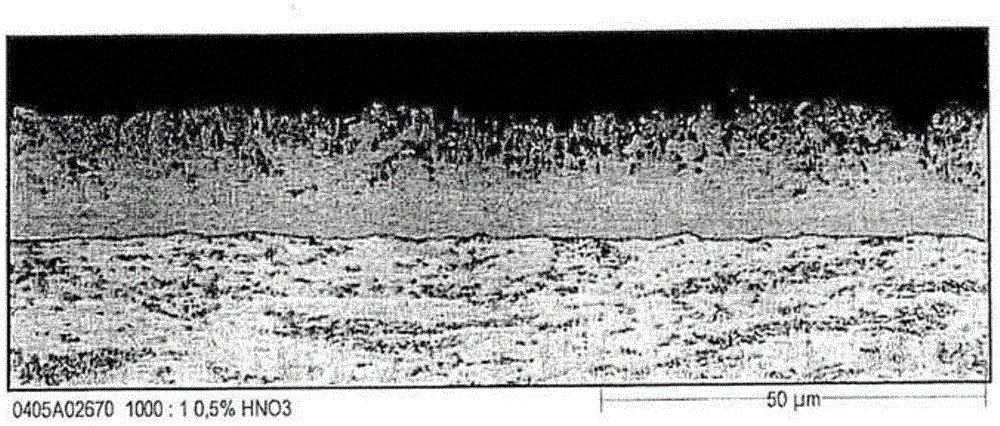

[0051] The cold-rolled strip after annealing is subjected to alkaline injection degreasing and electrolyte degreasing, the cold-rolled strip is made of steel containing 0.3-3% by weight of manganese, the steel has a yield limit of 150-1100MPa and a yield limit of 300- 1200MPa tensile strength. The degreasing basin contains a concentration of about 15g / L of a commercially available cleaner with greater than 25% sodium hydroxide, 1-5% fatty alcohol ether and 5-10% ethoxylated, acrylic acid Oxylated and methylated C12-18 alcohols. The cell temperature was approximately 65°C. The duration of jet degreasing is about 5 s. Followed by scrubbing. In the following process, the strip is hot-dipped (fire-coated). The metal melt is formed from an aluminum-zinc alloy comprising: 35-70% by weight of aluminum, 35-60% by weight of zinc, 0.1-10% by weight of magnesium, 0.1 to not more than 10% by weight of Si and Not higher than 5% by weight of Fe. In addition, the aluminum-zinc alloy pr...

example 2

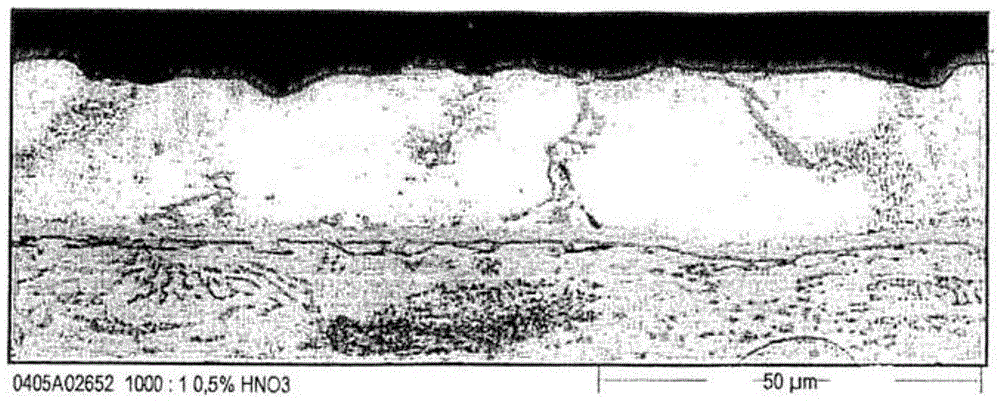

[0053] Hot-rolled strip (pickling) of steel grade 22MnB5 (1.5528) is degreased by alkaline injection and electrolyte. The strip is additionally brushed during alkaline jet degreasing. The degreasing basin contains a commercially available detergent having 5-10% sodium hydroxide and 10-20% potassium hydroxide at a concentration of approximately 20 g / L. The cell temperature was approximately 75°C. In the following process, the strip is hot-dipped (fire-coated). The metal melt is formed from an aluminum-zinc alloy containing: 35-70% by weight of aluminum, 35-60% by weight of zinc, 0.1-10% by weight of magnesium, 0.1 to 10% by weight of Si and not more than 5% by weight Fe. In addition, the aluminum-zinc alloy preferably also contains manganese and / or nickel in a total content of up to 15% by weight, wherein the manganese content can be up to 0.02% by weight. The overall layer thickness of the metal layer is adjusted by means of a grinding device (eg compressed air nozzle or i...

example 3

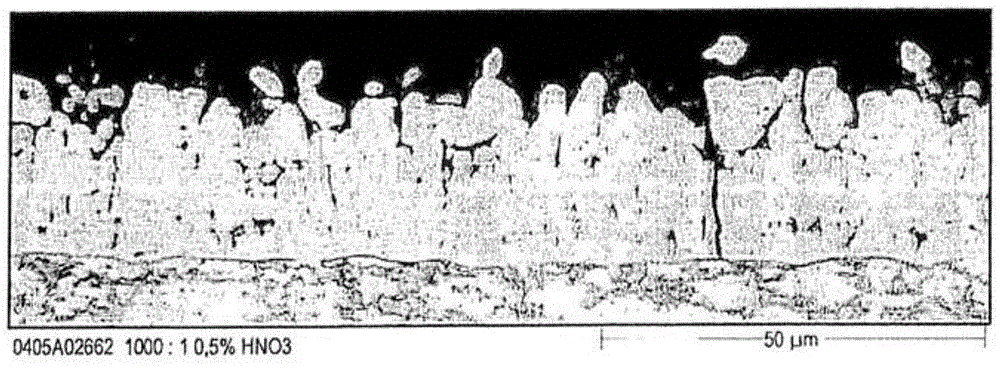

[0055] Similar to example 1 or 2, but with the difference that a so-called master alloy process is carried out after coating and before forming (press hardening). For this purpose, the flat steel product or slab is heated to a temperature in the range between 300° C. and 650° C., preferably between 350° C. and 600° C., so that iron enrichment occurs in the corrosion protection layer by diffusion processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com