Optical gas sensor and sensing system thereof

A sensing device, optical technology, applied in measuring devices, material analysis through optical means, electrical components, etc., can solve the problems of the overall responsivity decrease and thermal conductivity increase of the micro-thermal radiation sensor, and achieve high absorption rate , reduce energy loss, improve the effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the optical gas sensing device and its sensing system according to the present invention will be described below with reference to the relevant drawings. For ease of understanding, the same components in the following embodiments are described with the same symbols.

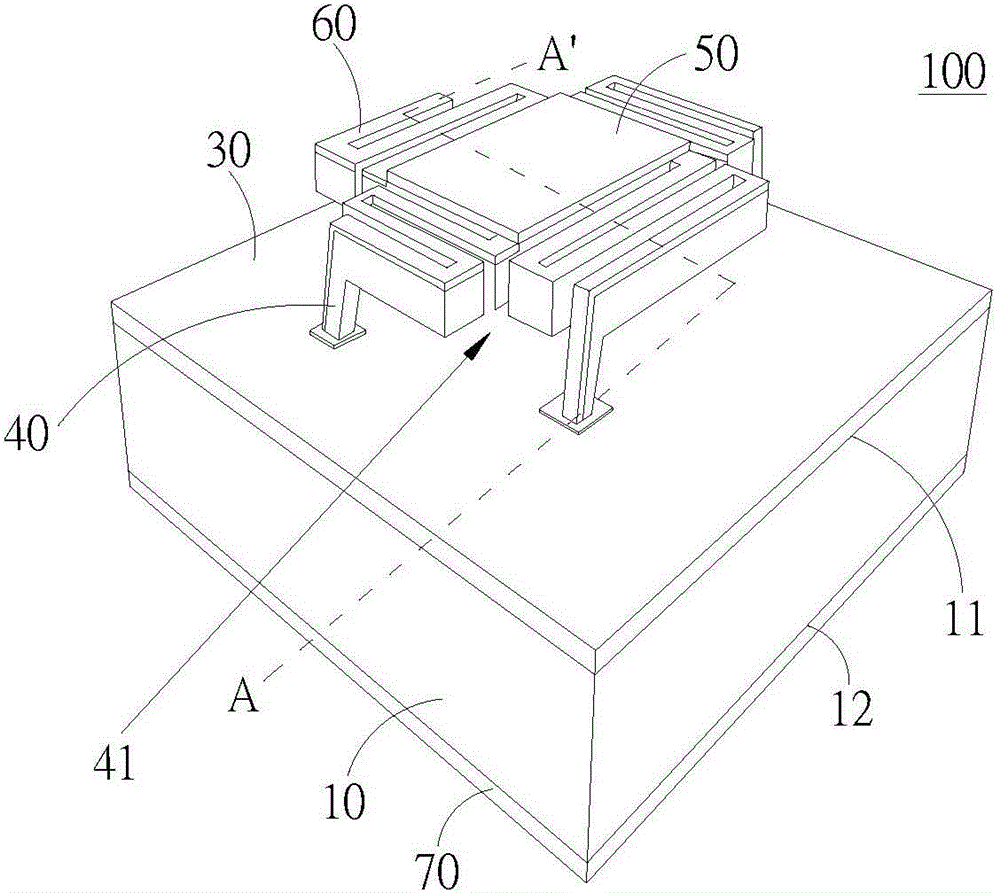

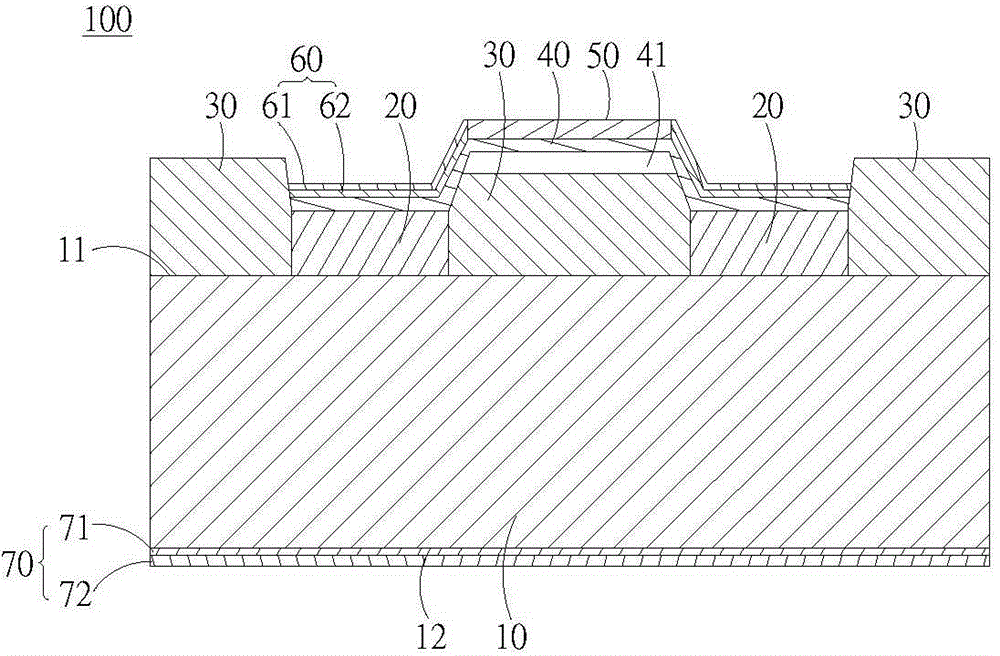

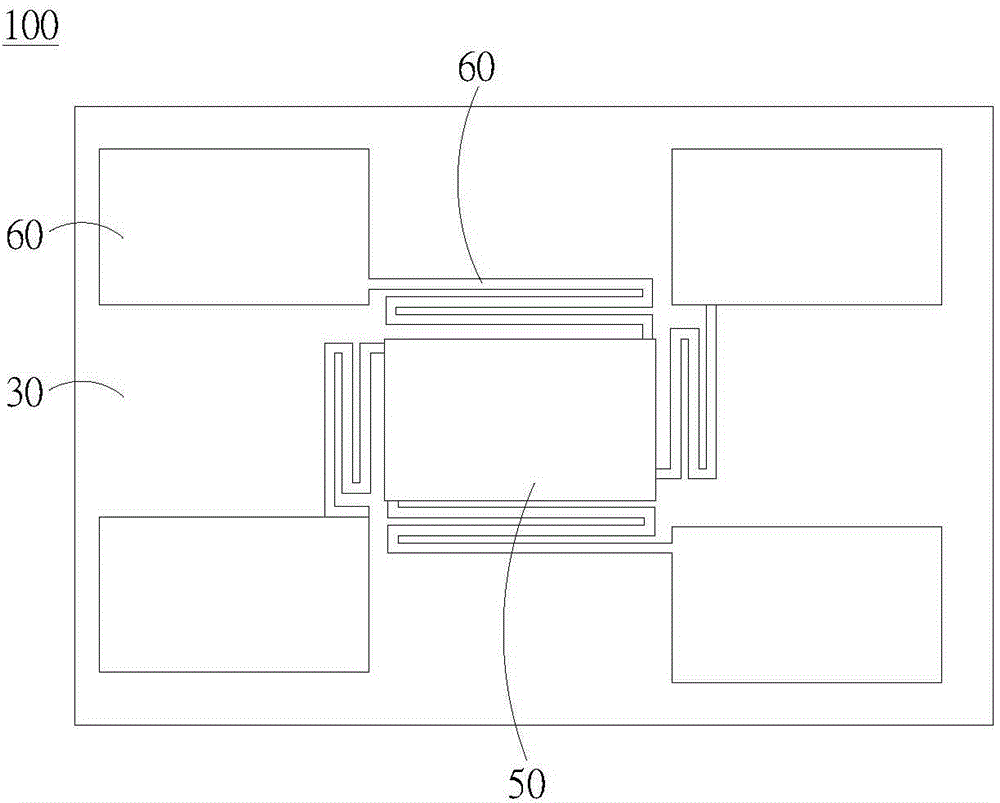

[0024] see Figure 1-3 , figure 1 It is a three-dimensional schematic diagram of a preferred embodiment of the optical gas sensing device of the present invention. figure 2 for figure 1 The optical gas sensing device is a side view of the substrate 10, the second electrode layer 70 and the reflective layer 30 cut along the section line A-A'. image 3 for figure 1 The top view of the optical gas sensing device.

[0025] The optical gas sensing device 100 of the present invention at least includes a substrate 10 , a plurality of electrode pads 20 , a reflective layer 30 , a sensing layer 40 , an absorbing layer 50 , a first electrode layer 60 and a second electrode layer 70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com