A connectivity detection method for an aircraft template laser cutting programming graphics

A connectivity inspection and laser cutting technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inaccurate inspection results, far different performance, poor graphics quality, etc., and achieve a leap in processing speed , the result is accurate, the effect of improving the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

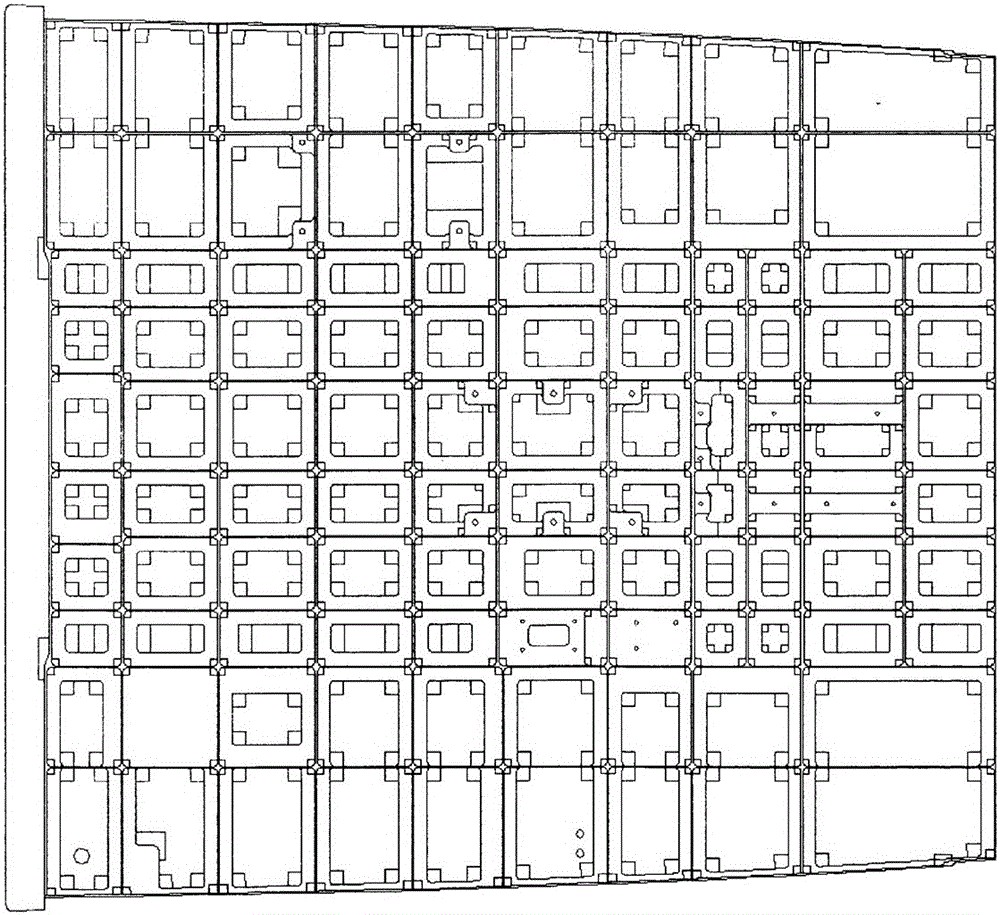

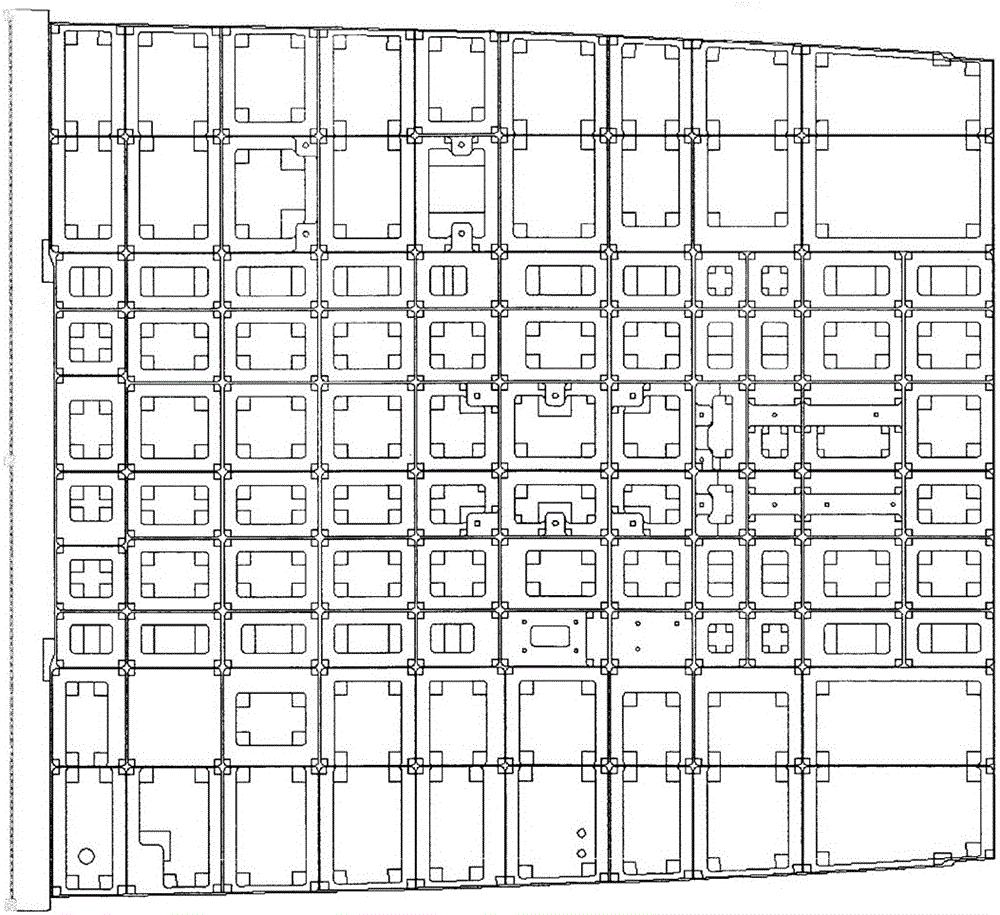

[0026] The method for checking the connectivity of programming graphics for laser cutting of aircraft templates is implemented as follows:

[0027] (1) First obtain all elements in the CAD two-dimensional graphics, and decompose the combined elements;

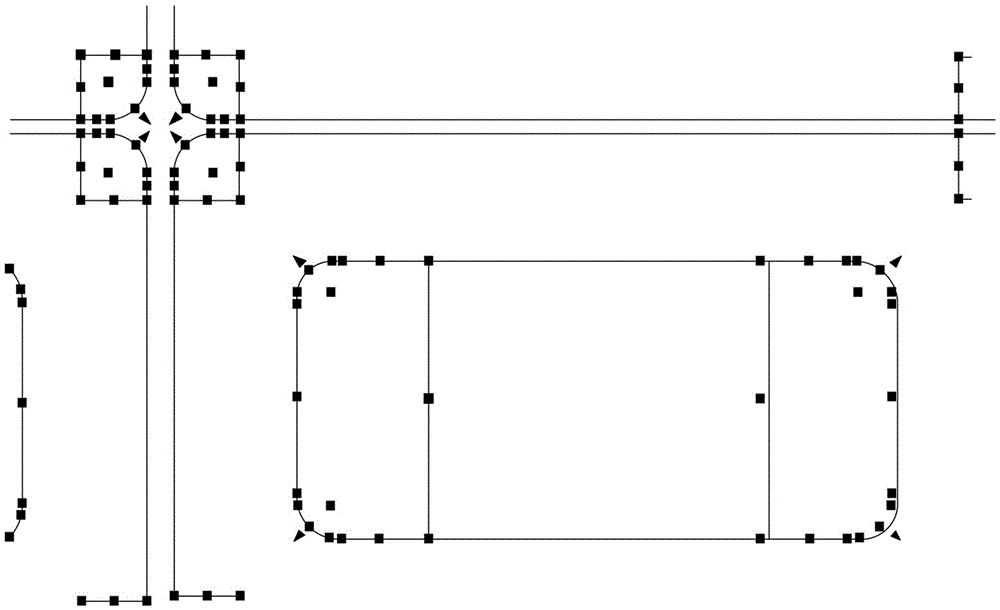

[0028] (2) Then the program-based AutomaticChain command starts from the first element in the search range, recursively searches for the elements associated with it, moves the found elements out of the search range and marks them; AutomaticChain quickly finds out in the graph all closed contours;

[0029] (3) Finally, the judgment of connectivity is realized based on the Chain command of the program, and the judgment result is displayed; Chain is to judge where the outline of the selected element is broken (or closed);

[0030] (4) Repeat steps (2) and (3) until there are no more elements in the search range.

[0031] The step (1) obtains the selected graphic elements, and decomposes the combined elements: prompt the user to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com