A high-efficiency energy-saving cold heading steel hot-rolled wire rod and its production method

A high-efficiency, energy-saving, hot-rolled wire rod technology, applied in the field of iron and steel manufacturing, can solve the problems of low hardenability and limited use of cold-headed steel hot-rolled wire rods, and achieve the goal of improving hot-working performance, quality, and hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The above-mentioned production method of high-efficiency and energy-saving cold heading steel hot-rolled wire rod, wherein the composition of cold heading steel includes by weight percentage: C content is 0.06%, Si content is 0.05%, Mn content is 0.42%, The P content is 0.01%, the S content is 0.01%, the Als content is 0.02%, the Ti content is 0.025%, the B content is 0.0045%, and the balance is Fe and unavoidable impurities. The heating process is to send the steel billet into the heating furnace and heat it to 1050°C; in the rolling process, the temperature for finishing rolling is 890-950°C; -900°C; the Stelmore roller table cooling process is to control the speed of the roller table to be 0.2-0.5m / s, and the cooling rate to be 0.5-5°C / s.

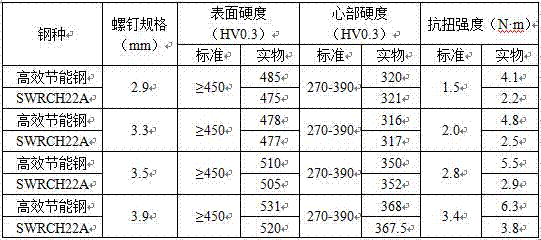

[0029] The following table is the performance comparison of products made of high-efficiency energy-saving cold heading steel and SWRCH22A in this embodiment

[0030]

Embodiment 2

[0032] The above-mentioned production method of a high-efficiency energy-saving cold heading steel hot-rolled wire rod, wherein the composition of the cold heading steel includes by weight percentage: C content is 0.13%, Si content is 0.05%, Mn content is 0.50%, P content is 0.01%, S content is 0.02%, Als content is 0.02%, Ti content is 0.02%, B content is 0.004%, V content is 0.015%, Co content is 0.005%, the balance is Fe and unavoidable Impurities.

[0033] The following table is the performance comparison of products made of high-efficiency energy-saving cold heading steel and SWRCH22A in this embodiment

[0034]

Embodiment 3

[0036]The above-mentioned production method of a high-efficiency energy-saving cold heading steel hot-rolled wire rod, wherein the composition of the cold heading steel includes by weight percentage: a C content of 0.08%, a Si content of not more than 0.03%, and a Mn content of 0.65% %, P content is 0.005%, S content is 0.008%, Als content is 0.03%, Ti content is 0.02%, B content is 0.004%, V content is 0.008%, Co content is 0.005%, and the balance is Fe and not Avoid impurities.

[0037] The following table is the performance comparison of products made of high-efficiency energy-saving cold heading steel and SWRCH22A in this embodiment

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com