Intelligent repair trace lubricating oil and preparation method thereof

An intelligent repair and lubricating oil technology, applied in the field of lubrication, can solve problems such as large amount of lubricating oil used, service life of unrepairable parts, shortened service life of guide rails and bearings, etc., and achieves good biodegradability, remarkable environmental protection effect, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

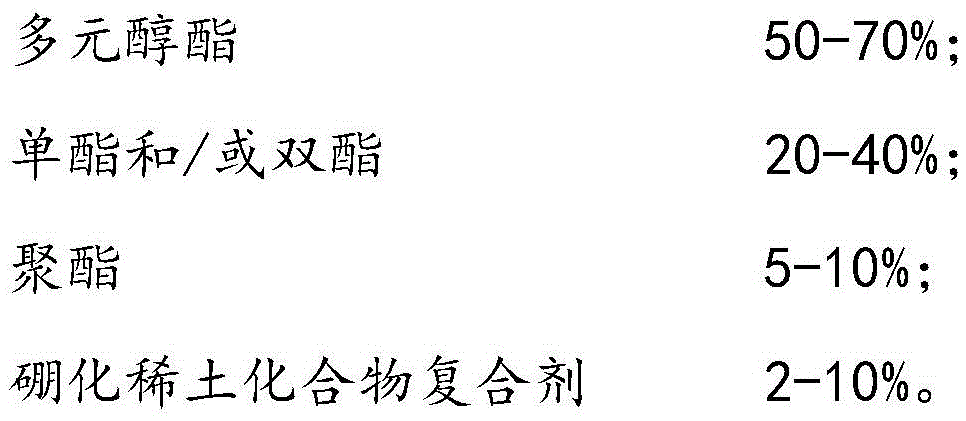

[0046] Weigh 70kg of trimethylolpropane oleate, 20kg of methyl oleate, 6kg of polyester (Priolube3986), and 4kg of boride rare earth compound compound (SK6109) into a stirrer and stir for about 1 hour at a temperature of 50°C. Hours, when the sample is observed to be basically transparent, it is a kind of intelligent repair micro-lubricant.

[0047] The physical and chemical indicators of the above-mentioned intelligent repair micro-lubricating oil prepared by testing are as follows:

[0048] project

basic data

experimental method

Exterior

yellow transparent

Kinematic viscosity 40℃mm 2 / s

43

GB / T265

Pour point °C

-12

GB / T3535

Opening flash point ℃

168

GB / T3536

Density 20℃kg / m 3

925

GB / T1884

[0049]The above intelligent repair micro-lubricant was applied to the TIMKEN experimental machine for repair experiments:

[0050] Add 46# mechanical oil to the oi...

Embodiment 2

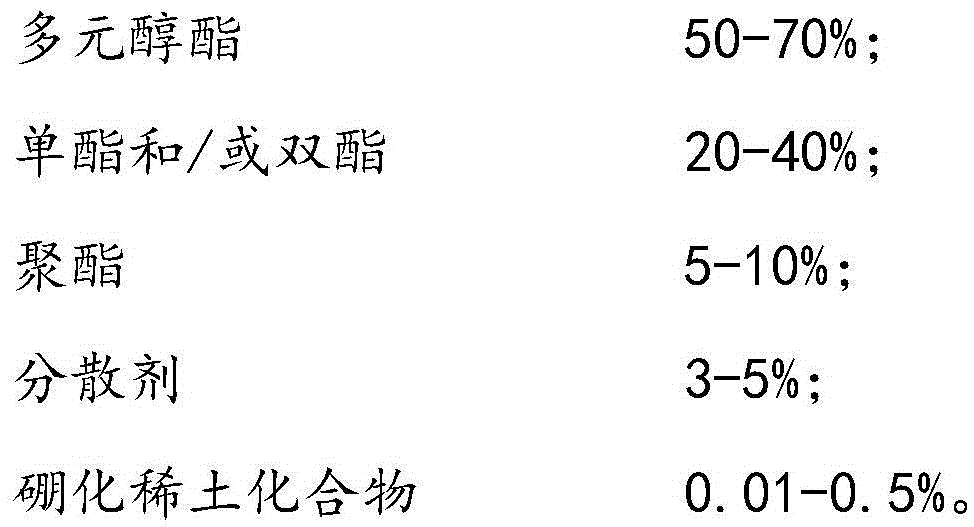

[0053] Weigh 0.5kg of lanthanum borate and add it into 5kg of dispersant T151A, heat and stir until completely dissolved, then add 50kg of pentaerythritol tetraoleate, 40kg of diisooctyl succinate, and 4.5kg of polyester (SYN-ESTERGY-10) into the mixer Stir at a temperature of 40°C for about 1 hour, and when the sample is observed to be basically transparent, it is a smart repair micro-lubricant.

Embodiment 3

[0055] Weigh 0.01kg of cerium borate and add it into 3.99kg of dispersant T152, heat and stir until completely dissolved, then add 60kg of pentaerythritol tetrapalmityl ester, 15kg of ethyl palmitate, 15kg of didecyl adipate, and 6kg of polyester (Hostagliss1510) in the mixer Stir at a temperature of 60°C for about 1 hour, and when the sample is observed to be basically transparent, it is a smart repair micro-lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com