A cleaning device and method for separating impurities in straw

A technology for cleaning devices and straws, applied in solid separation, chemical instruments and methods, classification, etc., can solve problems affecting the fermentation performance of straws, achieve the effect of promoting new rural construction, broadening the source of raw materials, and prolonging the link of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

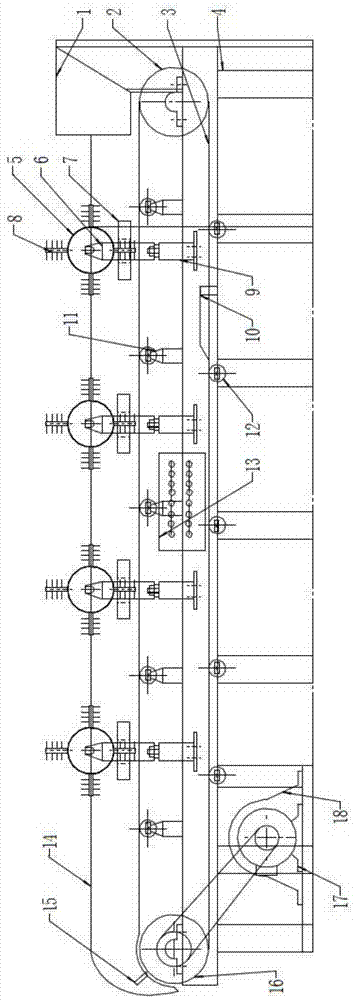

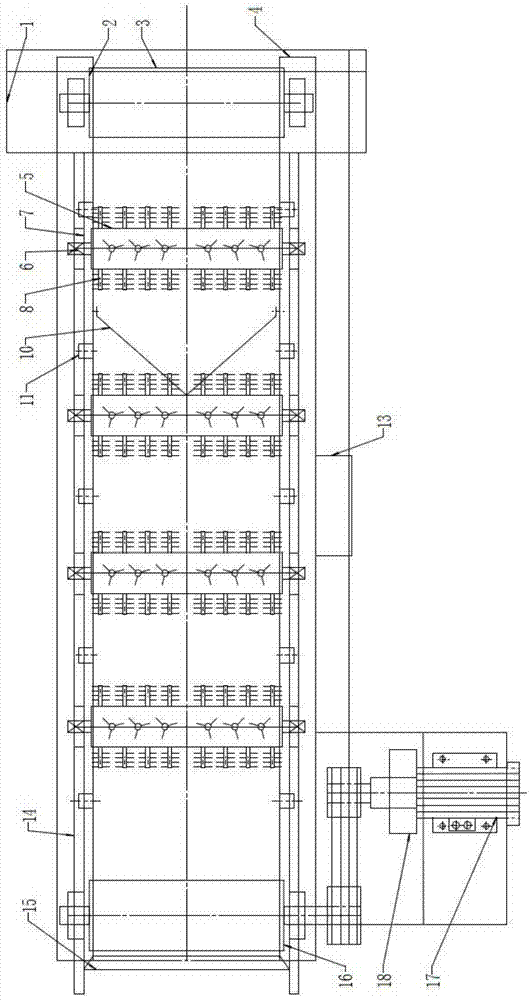

[0034] Embodiment: a kind of cleaning device that is used to separate the sundries in the straw, its structure is as follows figure 1 and figure 2 Shown: includes a conveyor 4, the conveyor 4 has a conveyor belt 3, one end of the conveyor 4 has a feeding mechanism, the other end is used for discharging under the guidance of the upper cleaning plate 15, and the conveyor 4 has a lower cleaning plate 10. It is used to clean up the debris attached to the conveyor belt;

[0035] A plurality of cleaning units are installed on the conveyor 4; each cleaning unit has an adjustment cylinder 9 installed on one side or both sides of the belt, the piston rod of the adjustment cylinder 9 is fixedly connected with the bracket 6, and a cleaning unit is installed on the bracket 6. The drum 5, the cleaning drum 5 is located directly above the conveyor belt 3;

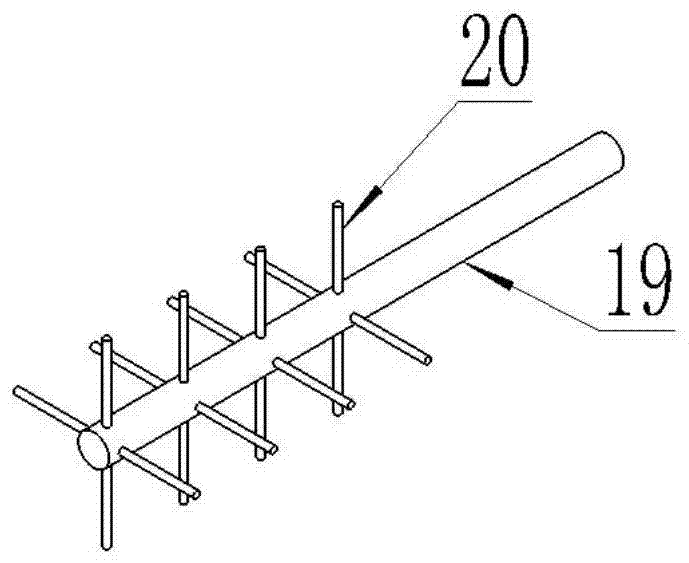

[0036] A plurality of cleaning teeth 8 are evenly distributed on the surface of the cleaning drum 5 , and the included angle formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com