Laser cutting machine with up and down exhaust system

A laser cutting machine and cutting head technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of smoke and dust dissipation, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

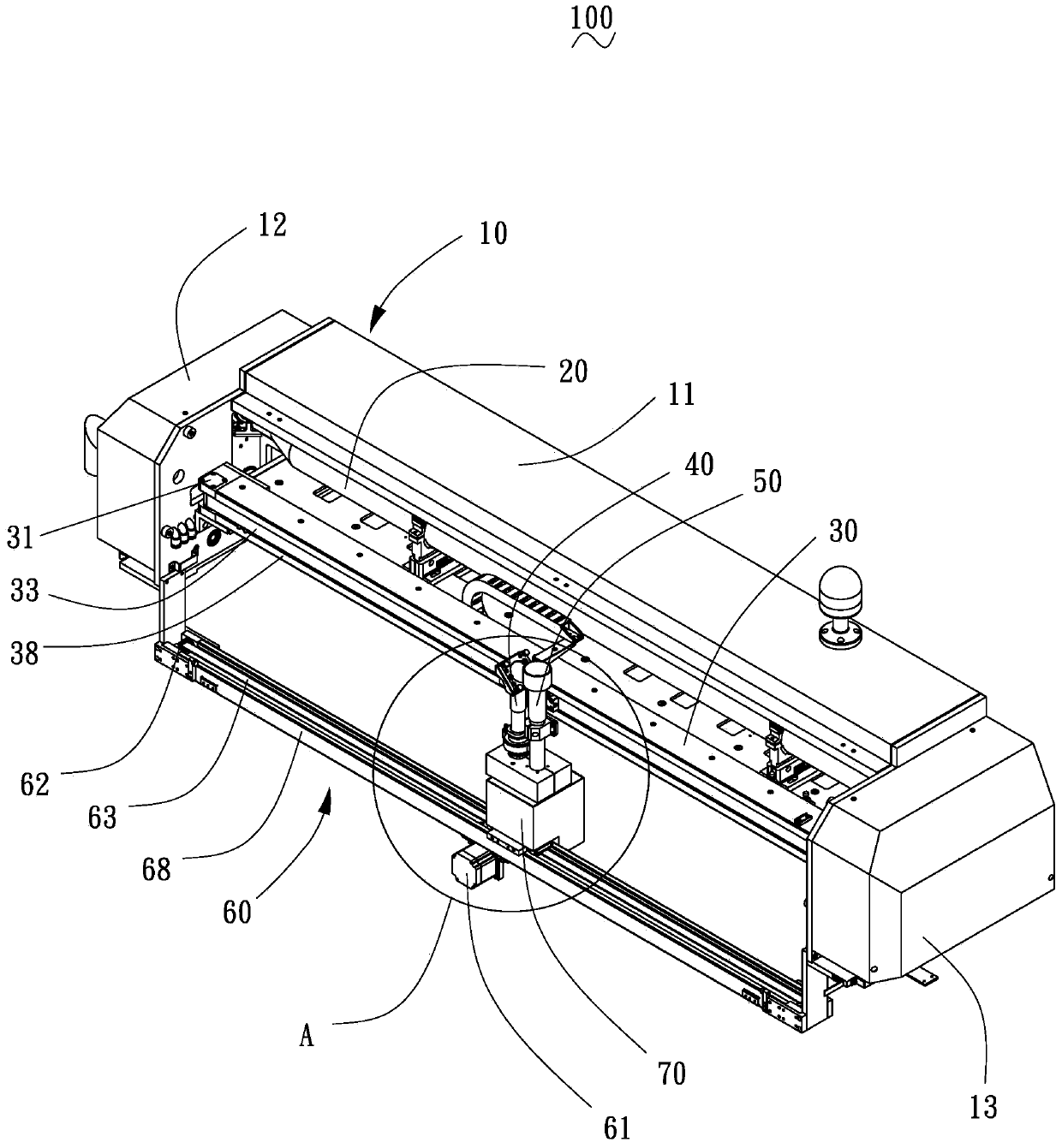

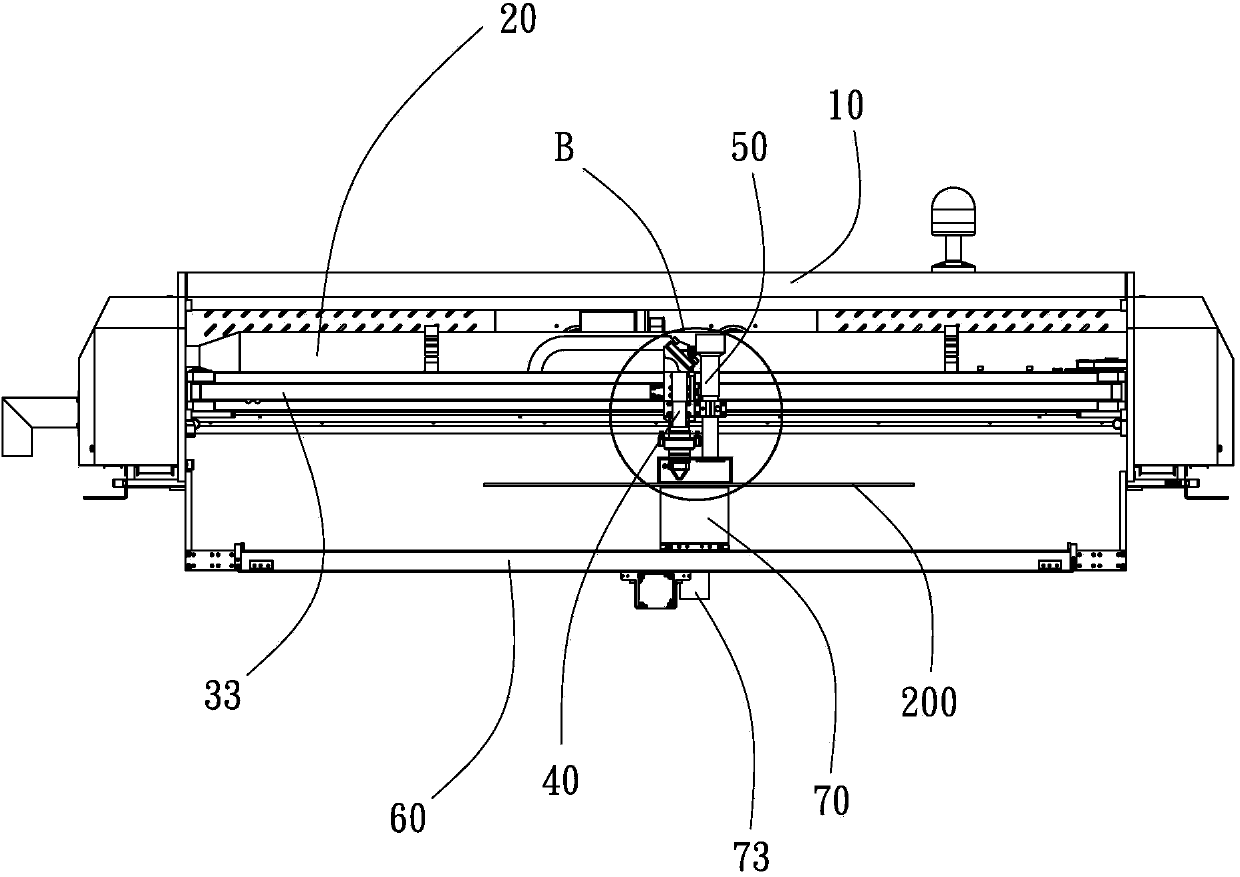

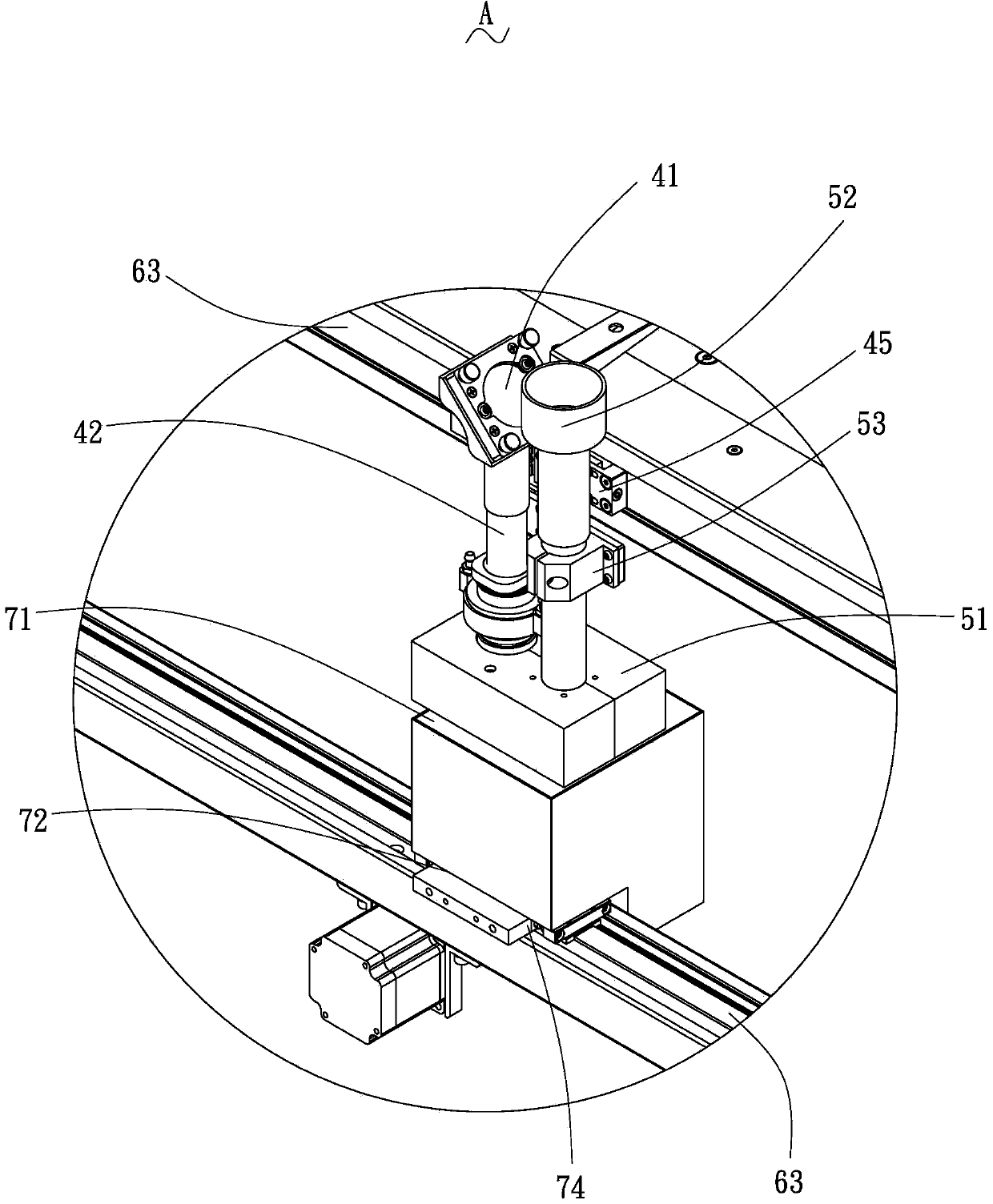

[0017] like Figure 1 to Figure 4 Shown is a laser cutting machine 100 with a vertical pumping system according to a preferred embodiment of the present invention, which is used to cut a flat plate-shaped material 200 to be cut. This laser cutting machine 100 with up and down pumping system includes a frame 10, a laser tube 20 installed in the frame 10, a first moving device 30 arranged on the top of the frame 10, connected with the first moving device 30 The cutting device 40 , the upper draft device 50 connected to the cutting device 40 , the second moving device 60 arranged at the bottom of the frame 10 , and the lower draft device 70 installed on the second moving device 60 . The material to be cut 200 is placed between the upper draft device 50 and the lower draft device 70, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com