Foam generator

A foam generator and foam technology, which are applied in fluid mixers, chemical instruments and methods, and mining fluids, etc., can solve the problems of unstable foam quality, prolonging the time of measures, simply venting and foaming agent solution, etc., to achieve foaming. Stable quality and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

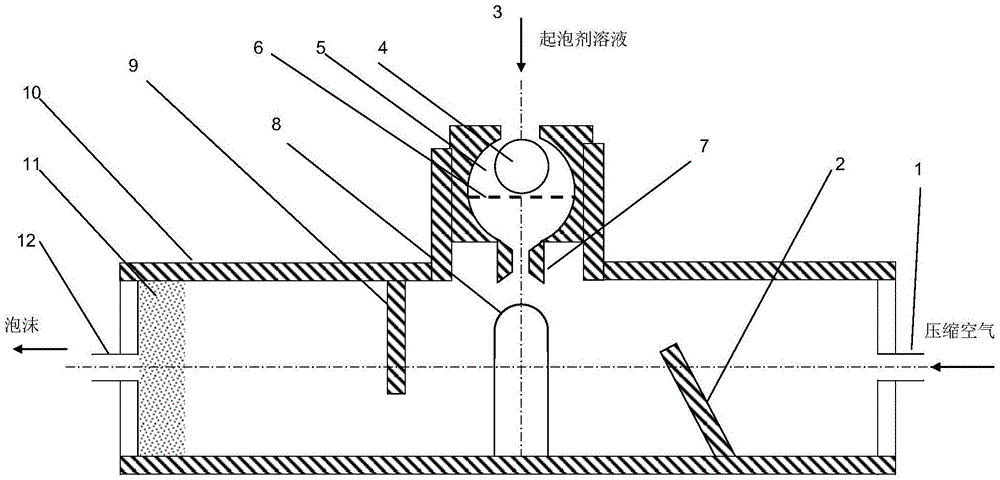

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, a foam generator includes a housing 10, one end of the housing 10 is provided with a compressed air inlet 1, the other end of the housing 10 is provided with a foam outlet 12, and the housing 10 is also provided with a The foaming agent solution inlet 3 for accelerating the foaming agent solution, the foaming agent solution inlet 3 communicates with the inner cavity of the housing 10; an atomizer 8 is arranged inside the housing 10, and the atomizer 8 Arranged at the position opposite to the foaming agent solution inlet 3 and on the path where compressed air flows in from the compressed air inlet 1, the atomizer 8 atomizes the foaming agent solution entering the inner cavity of the housing 10 from the foaming agent solution inlet 3 , the atomized foaming agent solution is fully mixed with the blown compressed air; a filter screen 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com