Method of prefabricating steel mesh

A technology of reinforcement mesh and main reinforcement, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of the overall durability of the reinforcement mesh, the overall anti-seismic characteristics, the overall compressive strength and the overall tensile strength reduction, and achieve work Improved efficiency and constructability, improved work efficiency and constructability, and reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

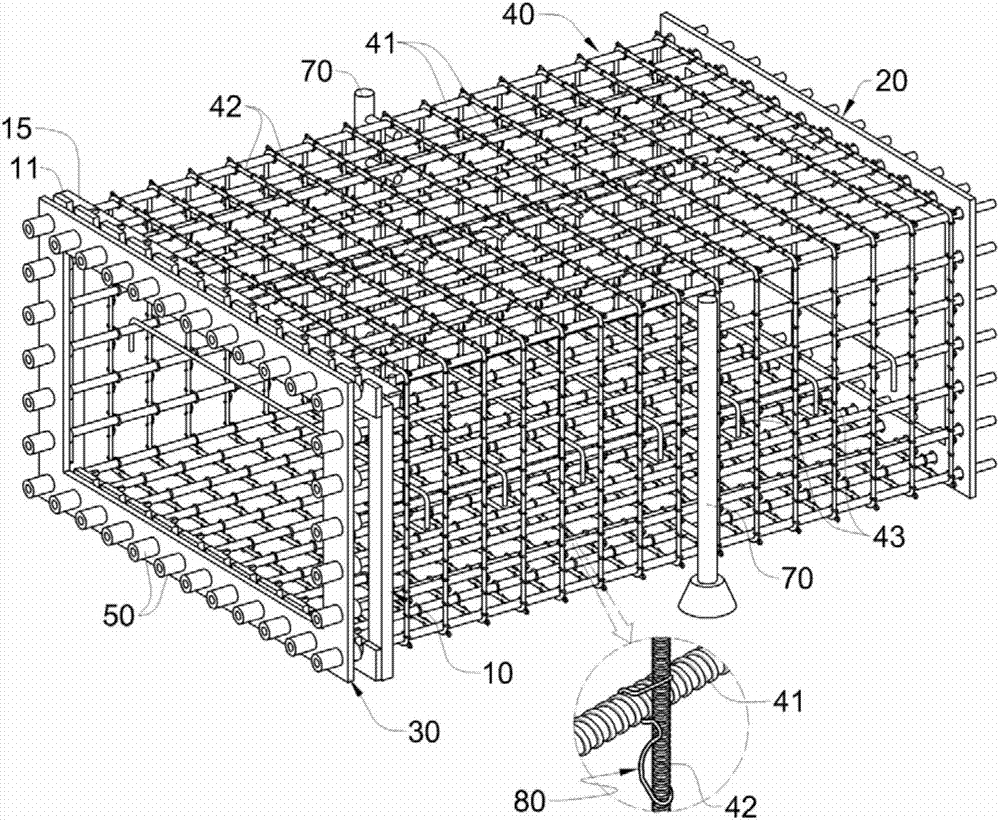

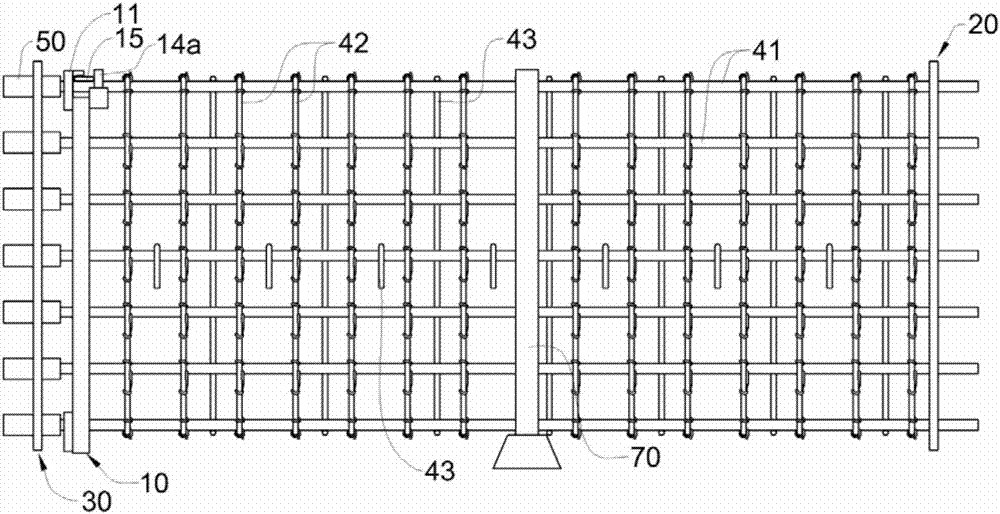

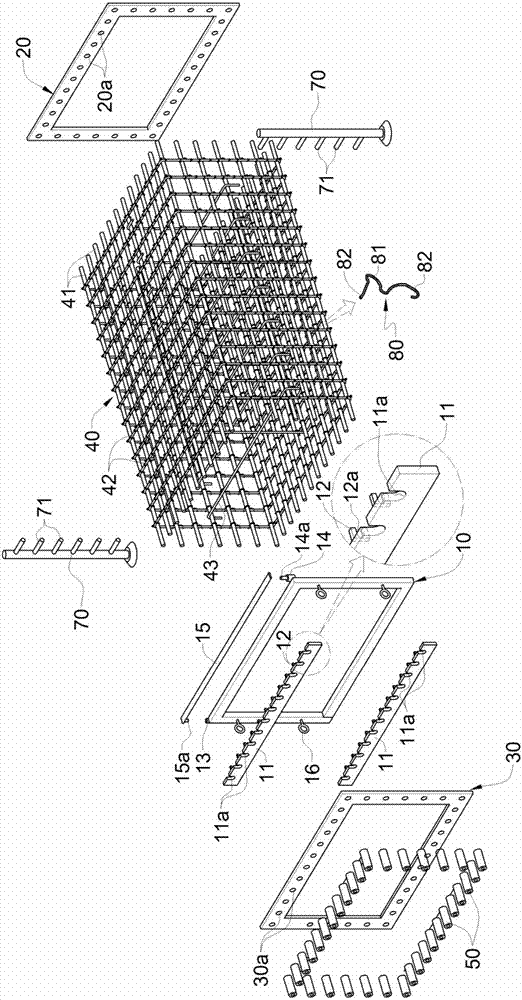

[0032] In the following, we will refer to Figure 1~Figure 9 The method of prefabricating the reinforcing steel mesh according to the present invention is more specifically described.

[0033] The present invention combines a plurality of steel bars used when constructing a building's uprights or beams (hereinafter collectively referred to as "columns"), namely main bars 41, hoops 42, and stirrups 43, thereby assembling a columnar steel bar mesh 40 on the ground, and The reinforcing steel mesh 40 is moved to a position for construction by a crane, thereby easily connecting and combining each main reinforcing steel 41 of the reinforcing steel mesh 40 and each main reinforcing steel 91 protruding from the upper surface of the thick plate 90 with each other.

[0034] All steel bars used in construction and civil engineering, such as threaded steel bars with spiral protrusions formed on the outer surface thereof, ring-shaped steel bars with a plurality of annular protrusions formed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com