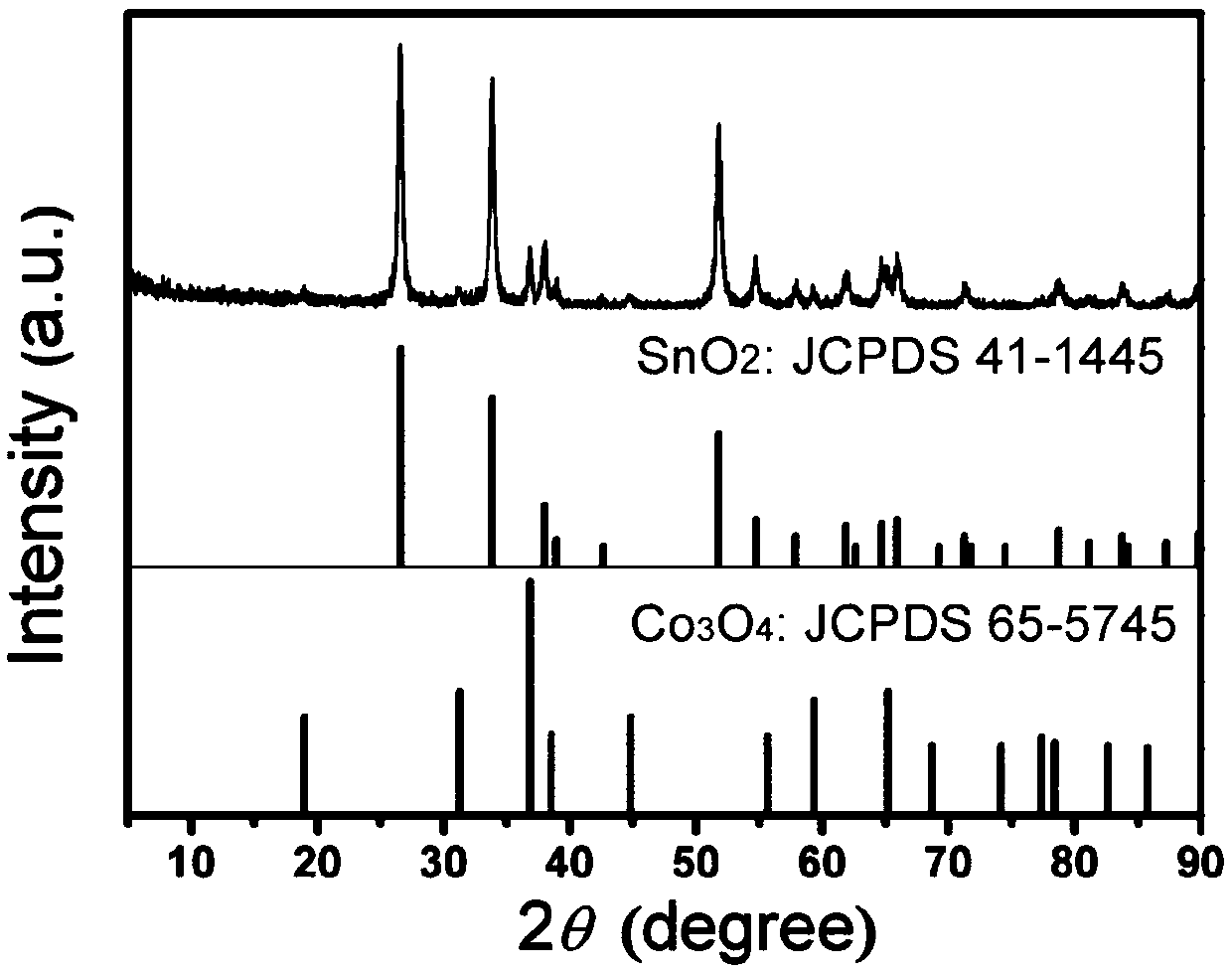

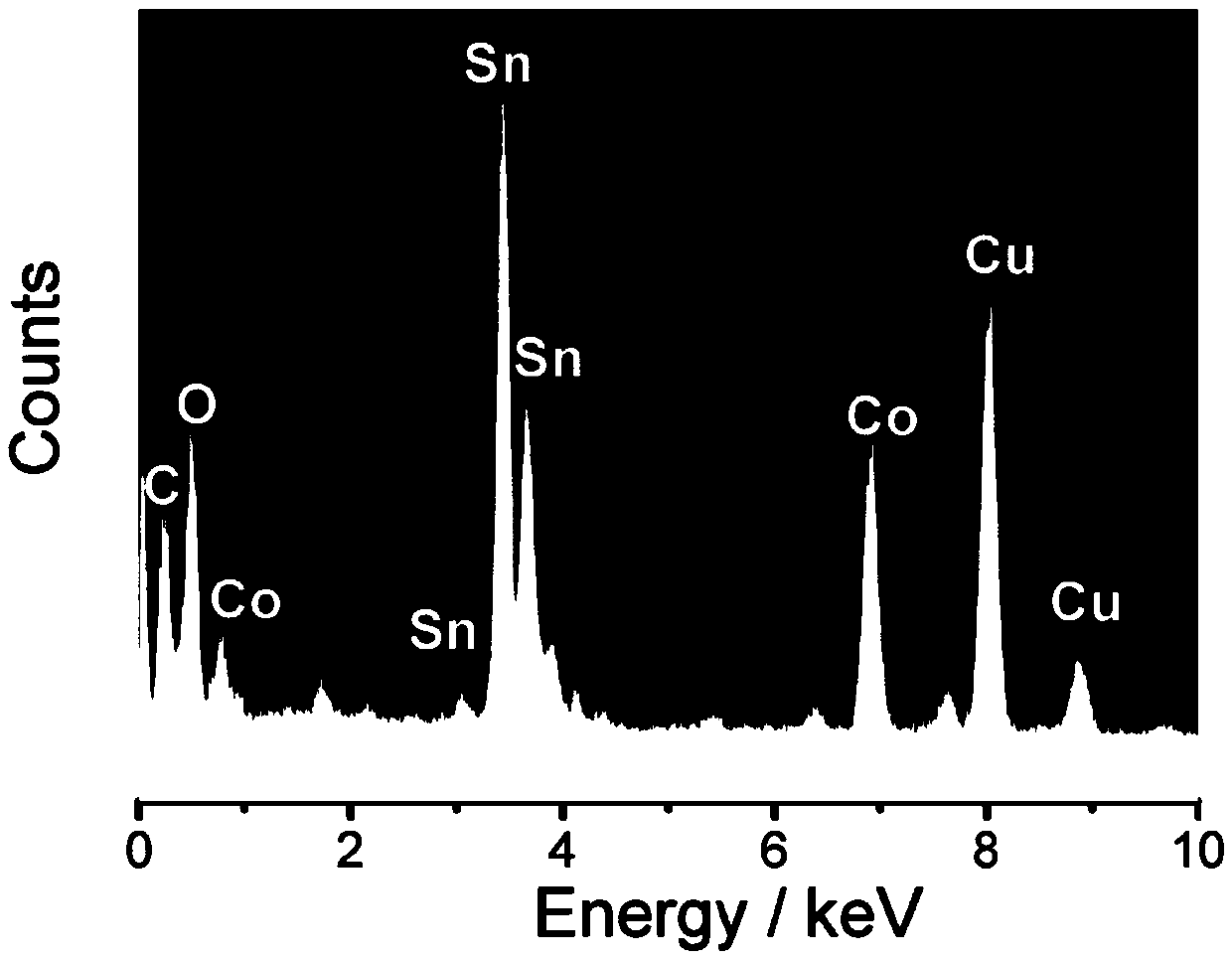

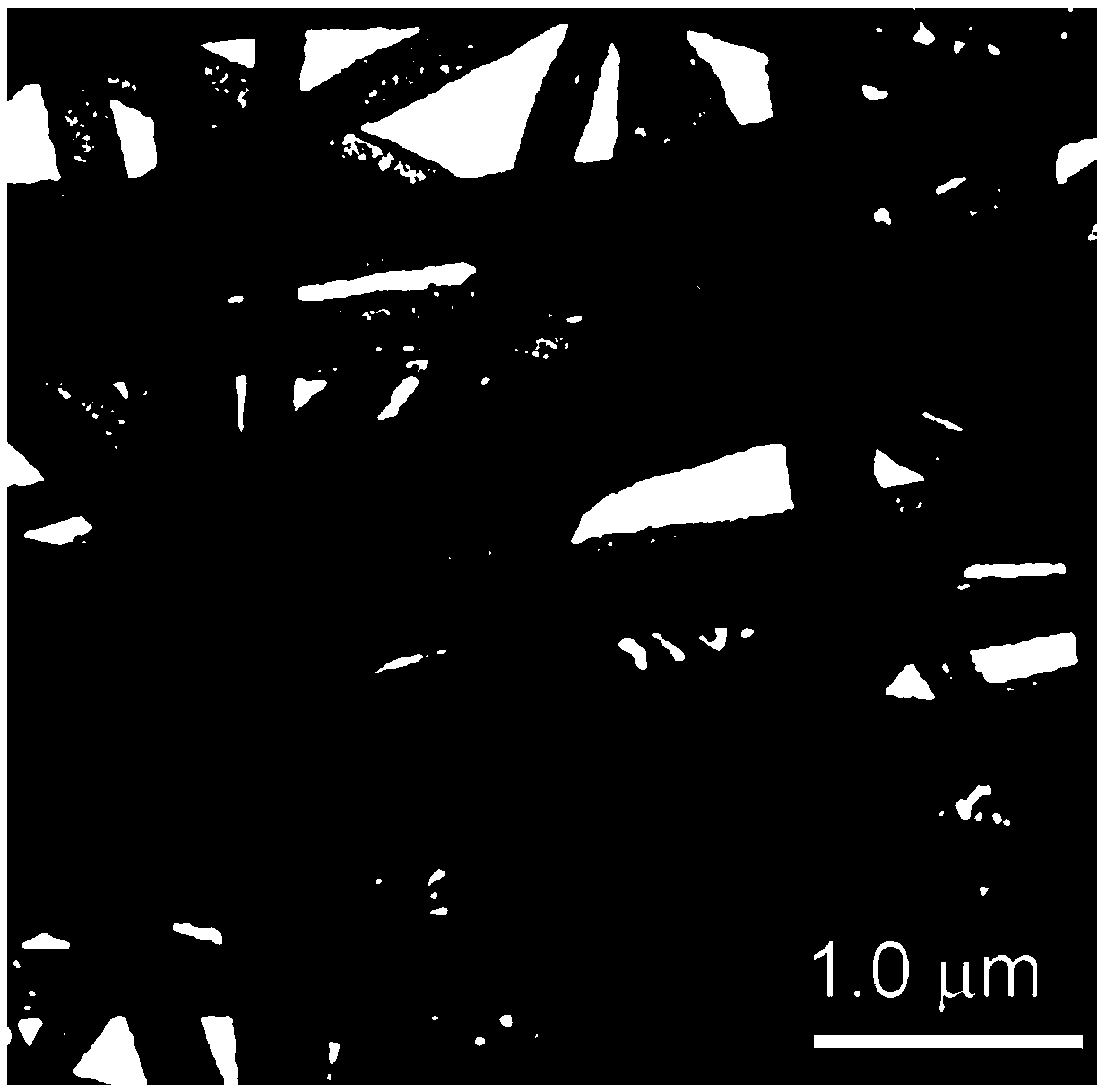

Hollow SnO2/Co3O4 hybrid nanotube as well as preparation method and application thereof

A nanotube and hybridization technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high requirements and narrow scope, and achieve uniform size, strong volume buffer capacity, high The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A hollow SnO 2 / Co 3 o 4 A method for preparing a hybrid nanotube, comprising the following steps:

[0042] 1) Preparation of electrospinning solution: cobalt nitrate as cobalt source, tin tetrachloride as tin source, polyvinylpyrrolidone (PVP) as working medium, organic solvent N,N-dimethylformamide (DMF) as dispersion agent, weigh 1g of PVP and put it into a beaker, add 10mL of DMF, stir magnetically at room temperature for 12h to dissolve the PVP, then weigh 0.5g of Co(NO 3 ) 2 ·6H 2 O and 0.5gSnCl 4 4H 2 0, slowly added in the transparent and clear PVP solution, continued magnetic stirring for 24h, and then the uniformly dispersed electrospinning solution obtained was packed into the sample tube of the electrospinning apparatus;

[0043] 2) Preparation of PVP nanofibers containing Co(II) and Sn(IV): The pore size of the electrospinning spinneret is 0.6 mm, and the loaded electrospinning needle is fixed, and the electrospinning surface is received on a flat pl...

Embodiment 2

[0047] Prepare hollow SnO according to the same method as in Example 1 2 / Co 3 o 4 Hybrid nanotubes, the difference is that the preparation method of the step (1) electrospinning solution of this embodiment is: using cobalt nitrate as the cobalt source, tin tetrachloride as the tin source, PVP as the working medium, and the organic solvent DMF as the dispersion agent, weigh 1g of PVP and put it into a beaker, add 10mL of DMF, stir magnetically at room temperature for 12h to dissolve the PVP, then weigh 0.3g of Co(NO 3 ) 2 ·6H 2 O and 0.3gSnCl 4 4H 2 O, slowly add to the transparent and clear PVP solution, continue magnetic stirring for 24h, and then put the obtained uniformly dispersed electrospinning solution into the sample tube of the electrospinning apparatus.

Embodiment 3

[0049] Prepare hollow SnO according to the same method as in Example 1 2 / Co 3 o 4 Hybrid nanotubes, the difference is that the preparation method of the step (1) electrospinning solution of this embodiment is: take cobalt nitrate as the cobalt source, tin tetrachloride as the tin source, PVP as the working medium, and the organic solvent DMF as the dispersant , Weigh 1g of PVP into a beaker, add 10mL of DMF, stir magnetically at room temperature for 12h to dissolve PVP, then weigh 0.4g of Co(NO 3 ) 2 ·6H 2 O and 0.4gSnCl 4 4H 2 O, slowly add to the transparent and clear PVP solution, continue magnetic stirring for 24h, and then put the obtained uniformly dispersed electrospinning solution into the sample tube of the electrospinning apparatus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com