A Fuel Assembly Fine Power Reconfiguration Method

A technology for fine power and fuel components, applied in instrumentation, computing, electrical and digital data processing, etc., can solve the problem that the calculation accuracy cannot meet the requirements, and achieve the effect of high accuracy, easy code reconstruction, and improved calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

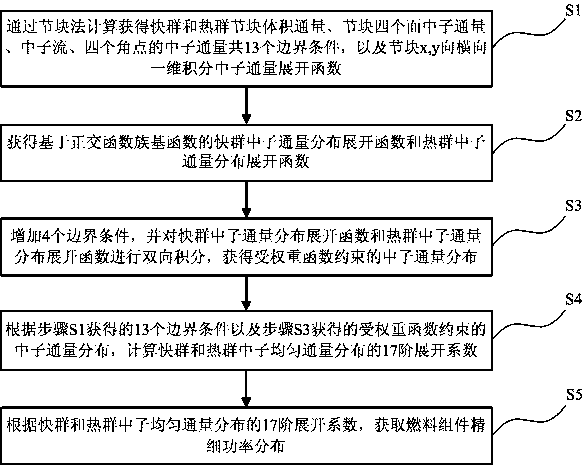

[0024] Please refer to figure 1 As shown, the embodiment of the present invention provides a fuel assembly fine power reconfiguration method, including:

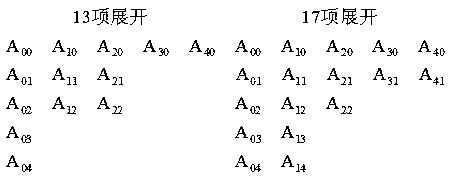

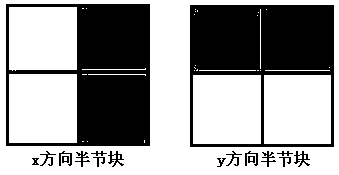

[0025] Step S1, calculate and obtain 13 boundary conditions of fast group and hot group nodal volume flux, neutron flux on four faces of nodal block, neutron flow, and neutron flux at four corner points by the nodal block method, and The horizontal one-dimensional integrated neutron flux expansion function of the node x, y;

[0026] Step S2, obtaining the fast group neutron flux distribution expansion function and the hot group neutron flux distribution expansion function based on the basis function of the orthogonal function family;

[0027] Step S3, adding 4 boundary conditions, and performing two-way integration on the fast group neutron flux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com