Layered parallel connection two-degree-of-freedom precise positioning platform based on flexible beams

A precision positioning and flexible beam technology, which is applied in the direction of machines/brackets, supporting machines, mechanical equipment, etc., can solve the problems such as the inevitable parasitic motion, and achieve the effect of compact structure, good motion decoupling characteristics, and small horizontal space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

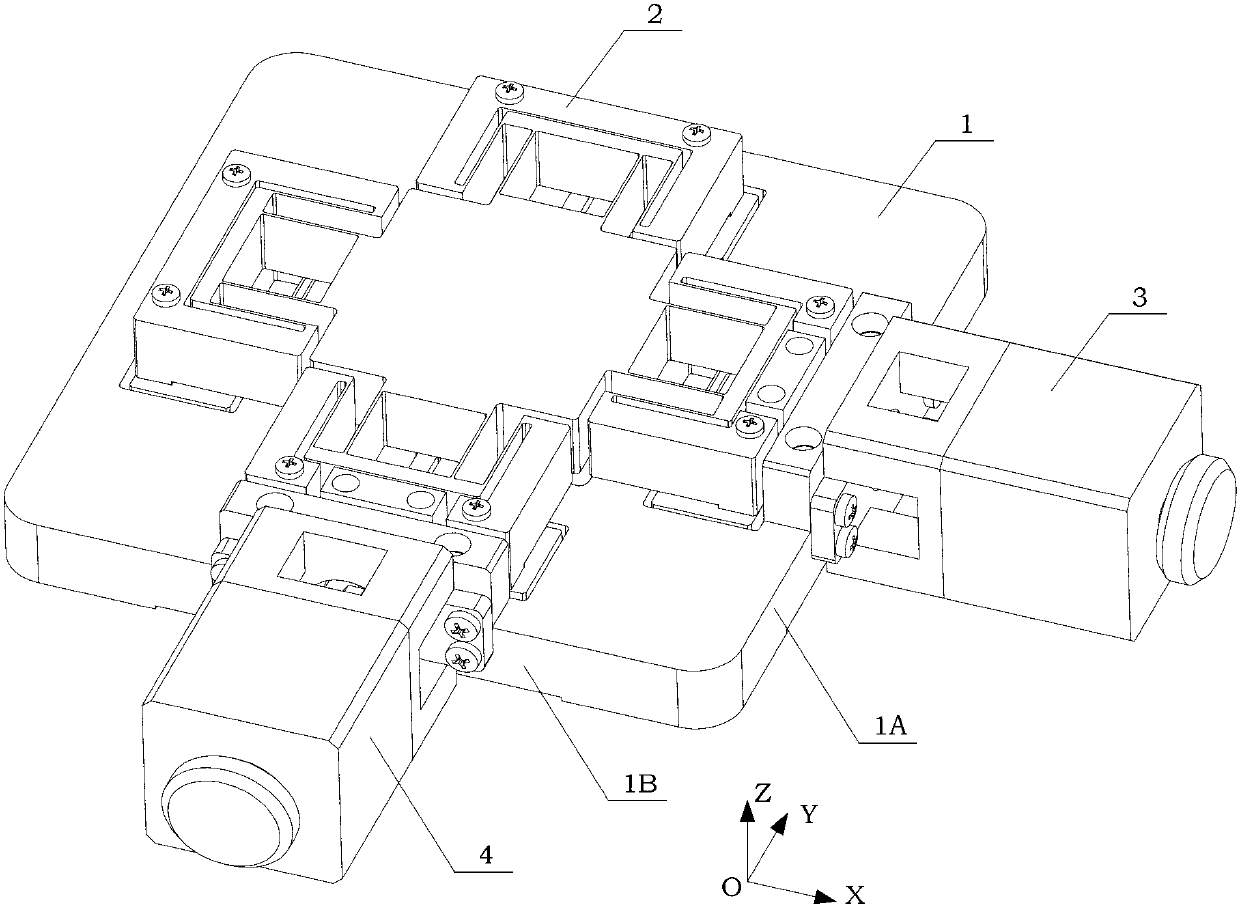

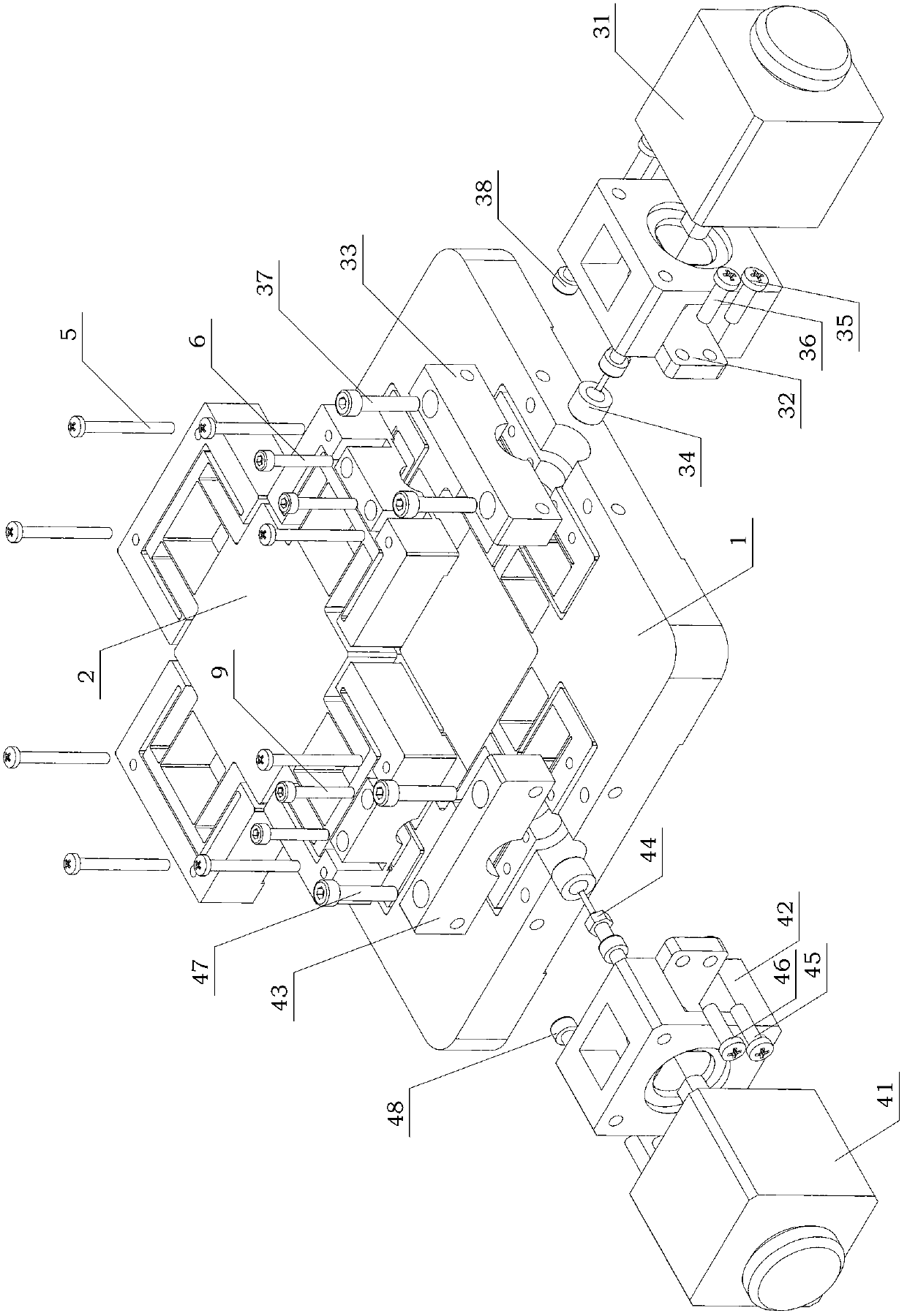

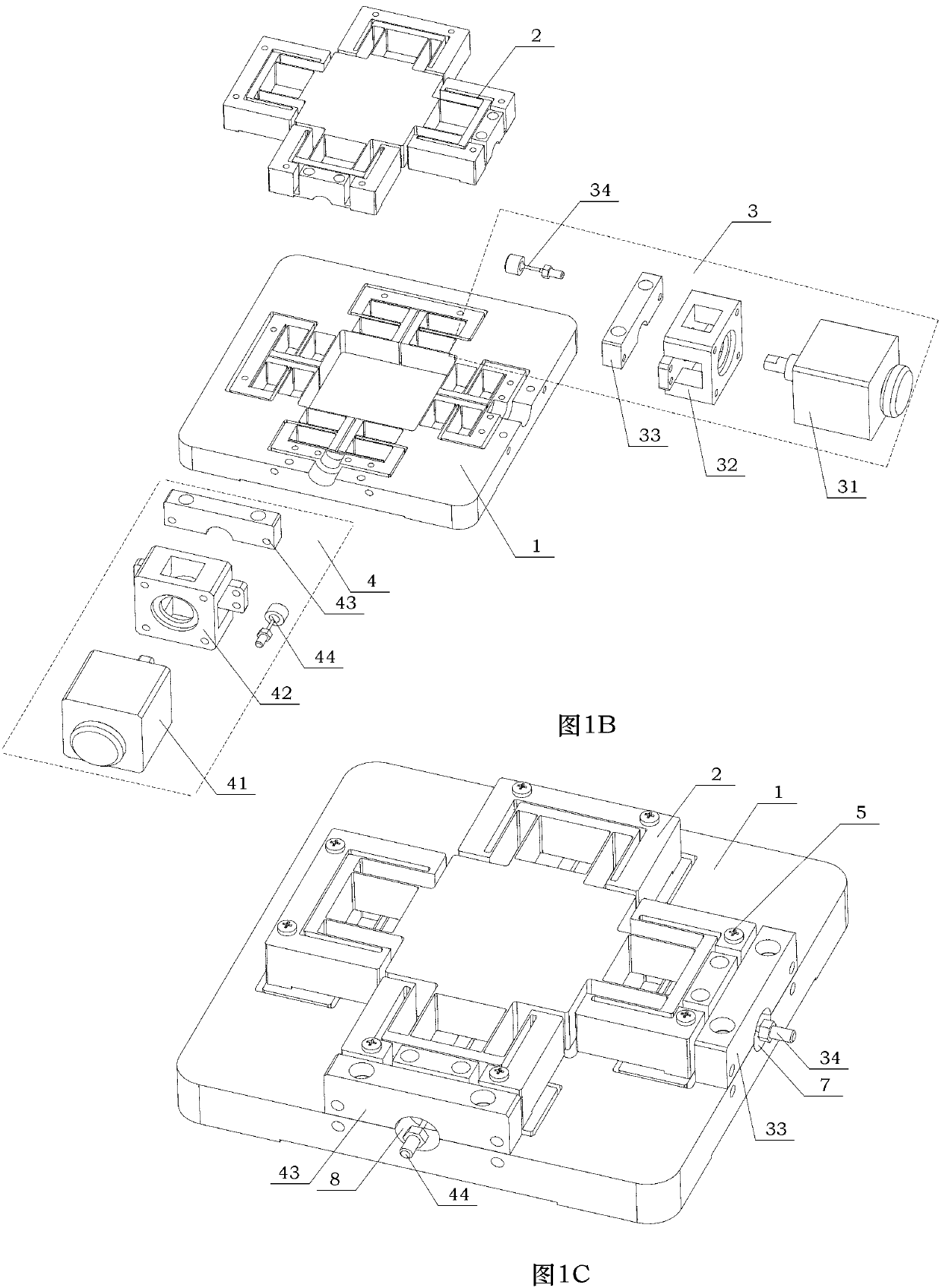

[0040] see figure 1 , Figure 1A , Figure 1B As shown, a stacked parallel two-degree-of-freedom precision positioning platform based on flexible beams of the present invention includes a lower guiding platform 1, an upper decoupling platform 2, an X-axis driving assembly 3 and a Y-axis driving assembly 4 .

[0041] Among them, eight ninth screws 5 , two tenth screws 6 and two eleventh screws 9 are used to realize fixed installation between the lower guiding platform 1 and the upper decoupling platform 2 . That is, eight ninth screws 5 respectively pass through the upper through holes 2K of the upper decoupling platform 2 and then threadedly connect to the lower threaded holes 1K of the lower guiding platform 1 . That is, two tenth screws 6 pass through the third counterbore 252 of the upper decoupling platform 2 and are screwed into the AC threaded holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com