VPX bus-based workpiece bench synchronous motion control system and method

A technology of synchronous motion and control system, applied in the direction of using feedback control, photolithography exposure device, microlithography exposure equipment, etc., to achieve the effect of flexible network topology, high reliability, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The content of the specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

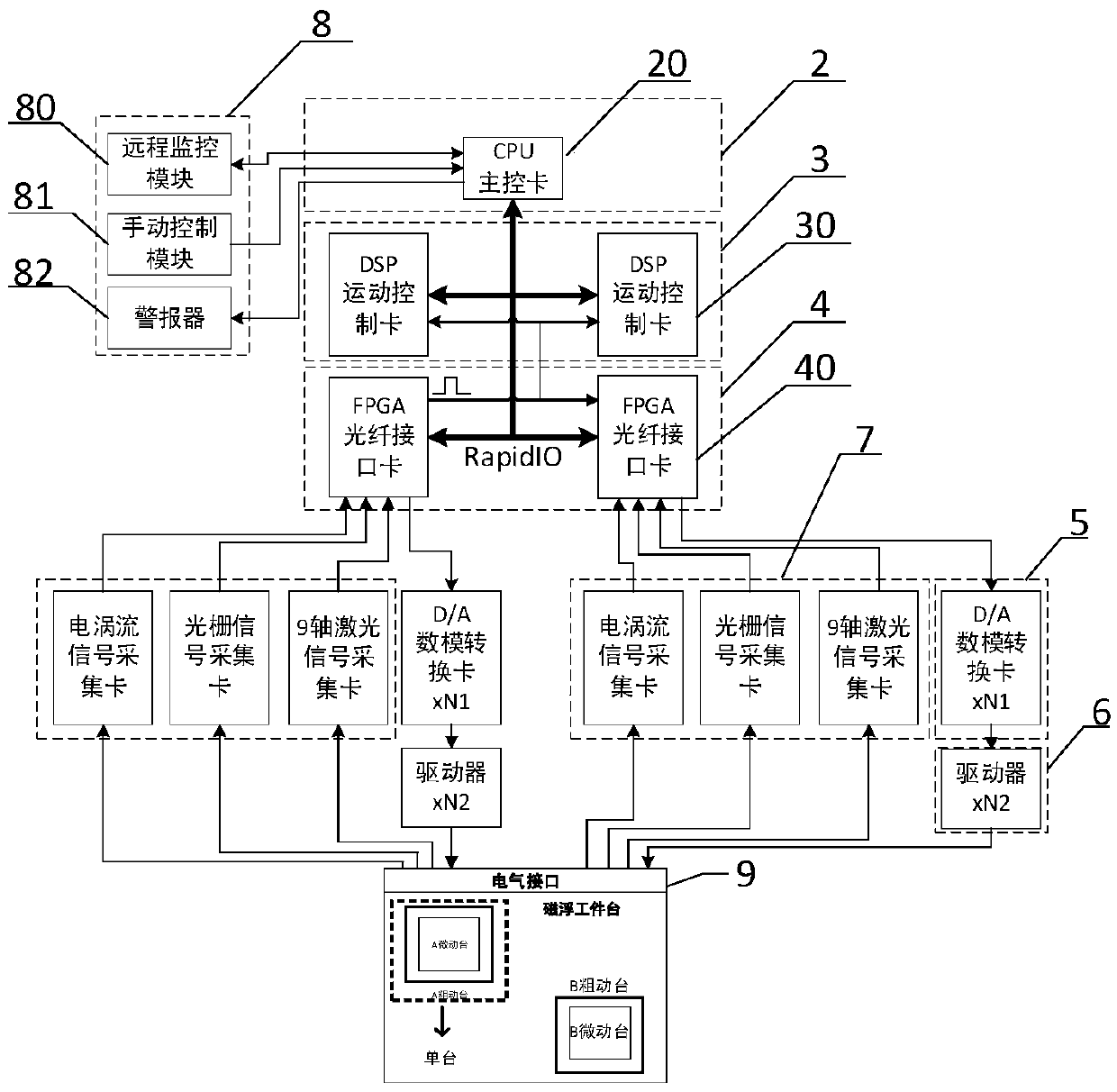

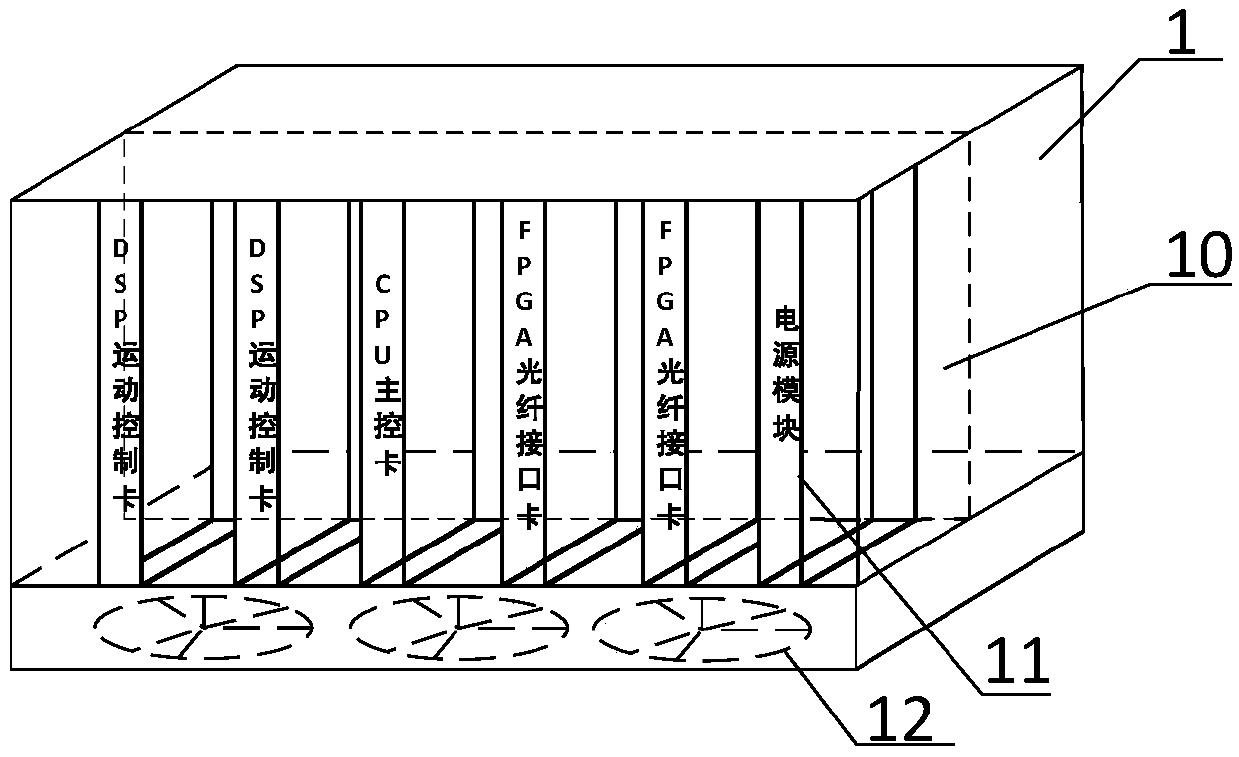

[0065] A kind of workpiece table synchronous motion control system based on VPX bus of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes VPX bus chassis, CPU main control unit, motion control unit, optical fiber interface unit, power amplifier unit, motor driver unit, measurement unit and human-computer interaction unit; the VPX chassis is provided with a 6U five-slot VPX back board, a power module and a plurality of cooling fans; the main control unit is a CPU main control card; the motion control unit includes one or two DSP motion control cards; the optical fiber interface unit includes one or two An FPGA fiber interface card; the CPU main control card, the DSP motion control card and the FPGA fiber interface card are all inserted on the V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com