A transformer simulation transportation test bench and its application

A transportation test and transformer technology, applied in the field of transformers, can solve the problems of bumpy transformers, only have up and down vibrations, and hidden safety hazards, and achieve the effects of verifying quality reliability, ingenious structural design, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

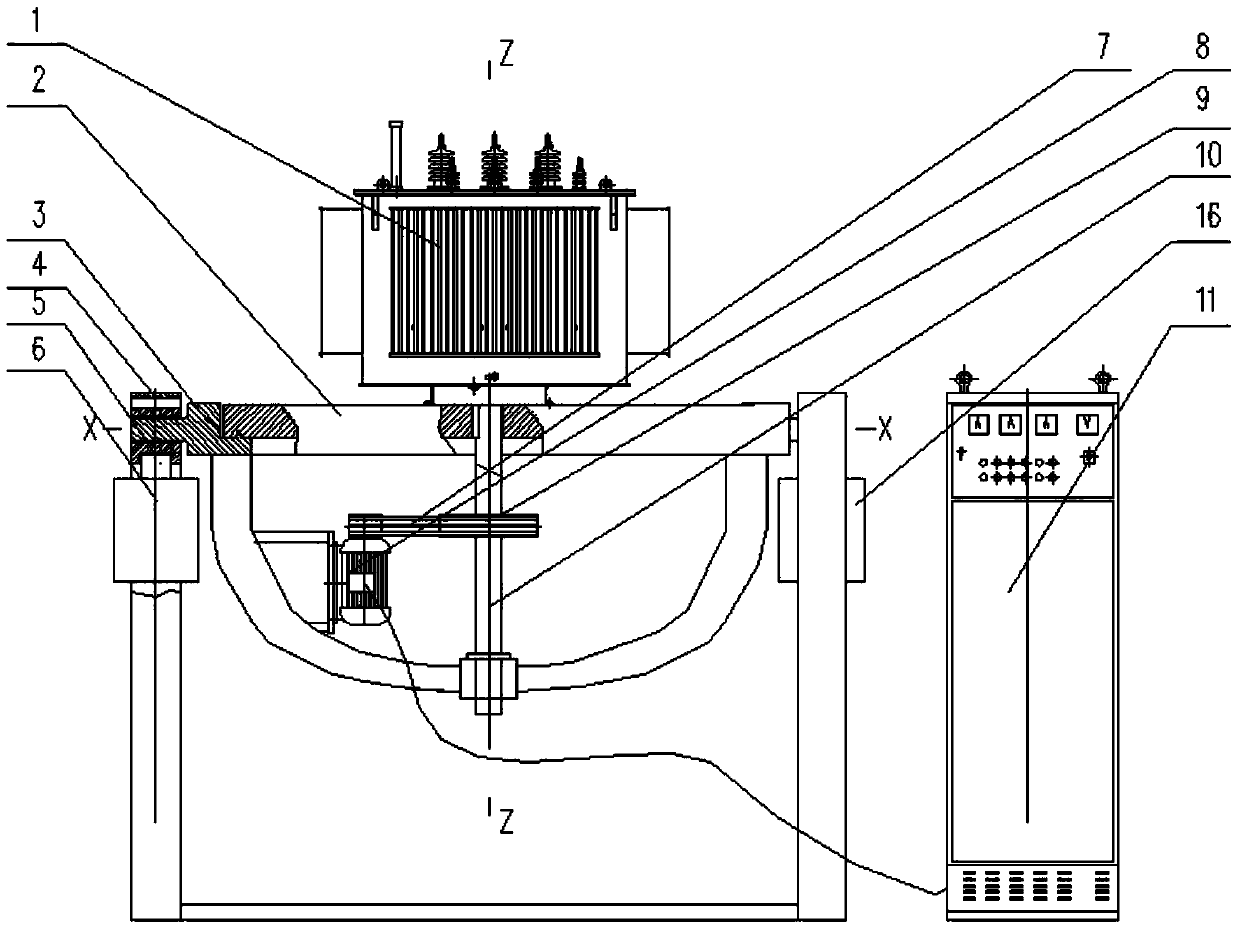

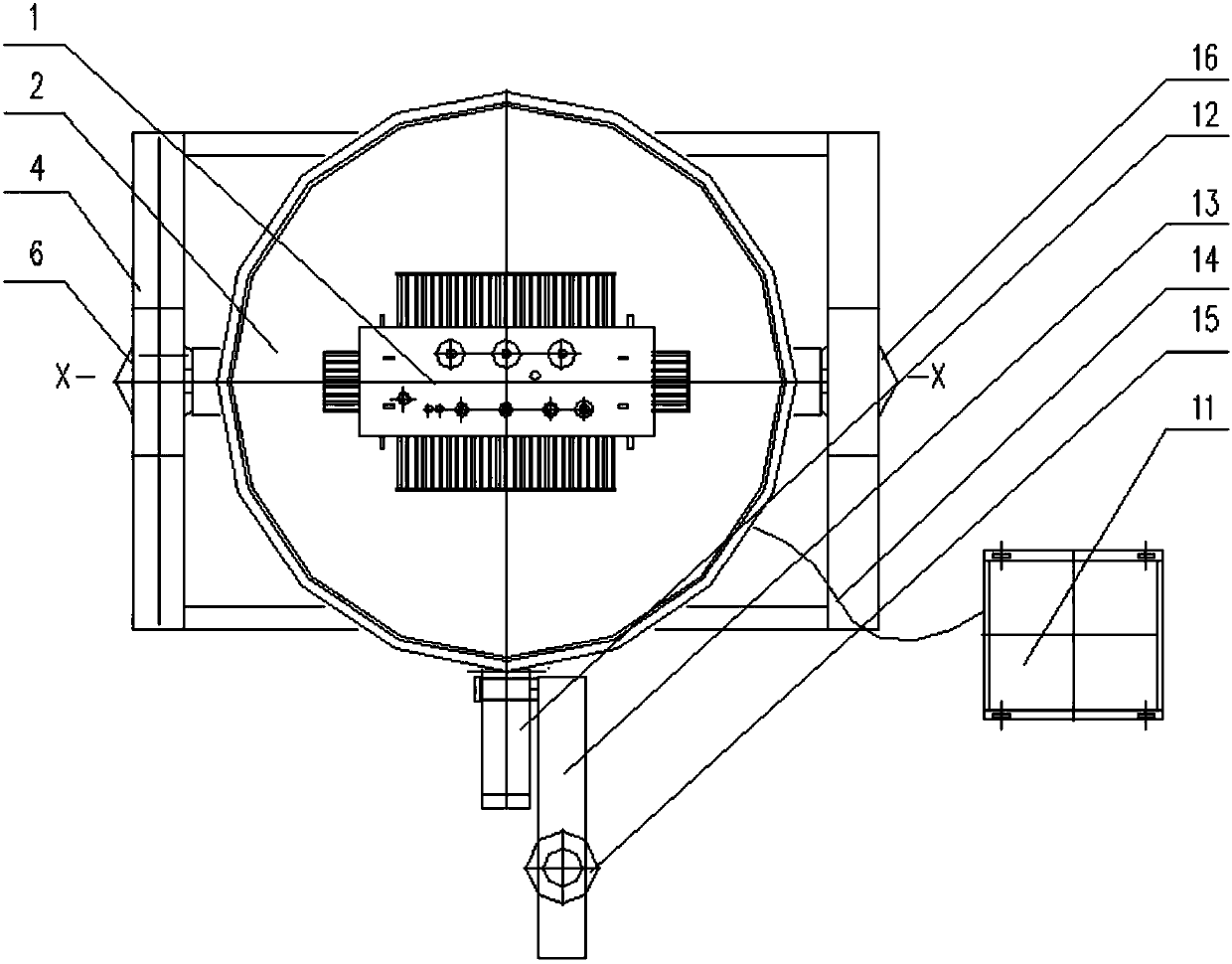

[0035] In this embodiment, the test bench is used to simulate the impact of the sudden braking of a road transport vehicle on the transformer:

[0036] Fix the transformer 1 with a rated capacity of 4000kVA and below and a weight of 4 tons or below on a circular rotating disk 2 with a diameter of 2500mm. The rotating disk 2 can rotate freely on the circular track of the disk bracket 3, and the speed can be 0-1000 R / M is adjusted, the transmission shaft 10 is rigidly connected to the rotary disc 2 through a key, and the disc bracket 3 is connected to the transmission shaft 10 through a bearing and supports the transmission shaft so that it can rotate; the speed regulating motor 8 is fixed on the chassis , and drive the belt 7 to drive the pulley 9, drive the transmission shaft 10 to rotate, and then the rotating disk 2 and the transmission shaft 10 rotate synchronously. The principle is: the transformer rotates on the rotating disk, and it will bear the impact of centrifugal fo...

Embodiment 2

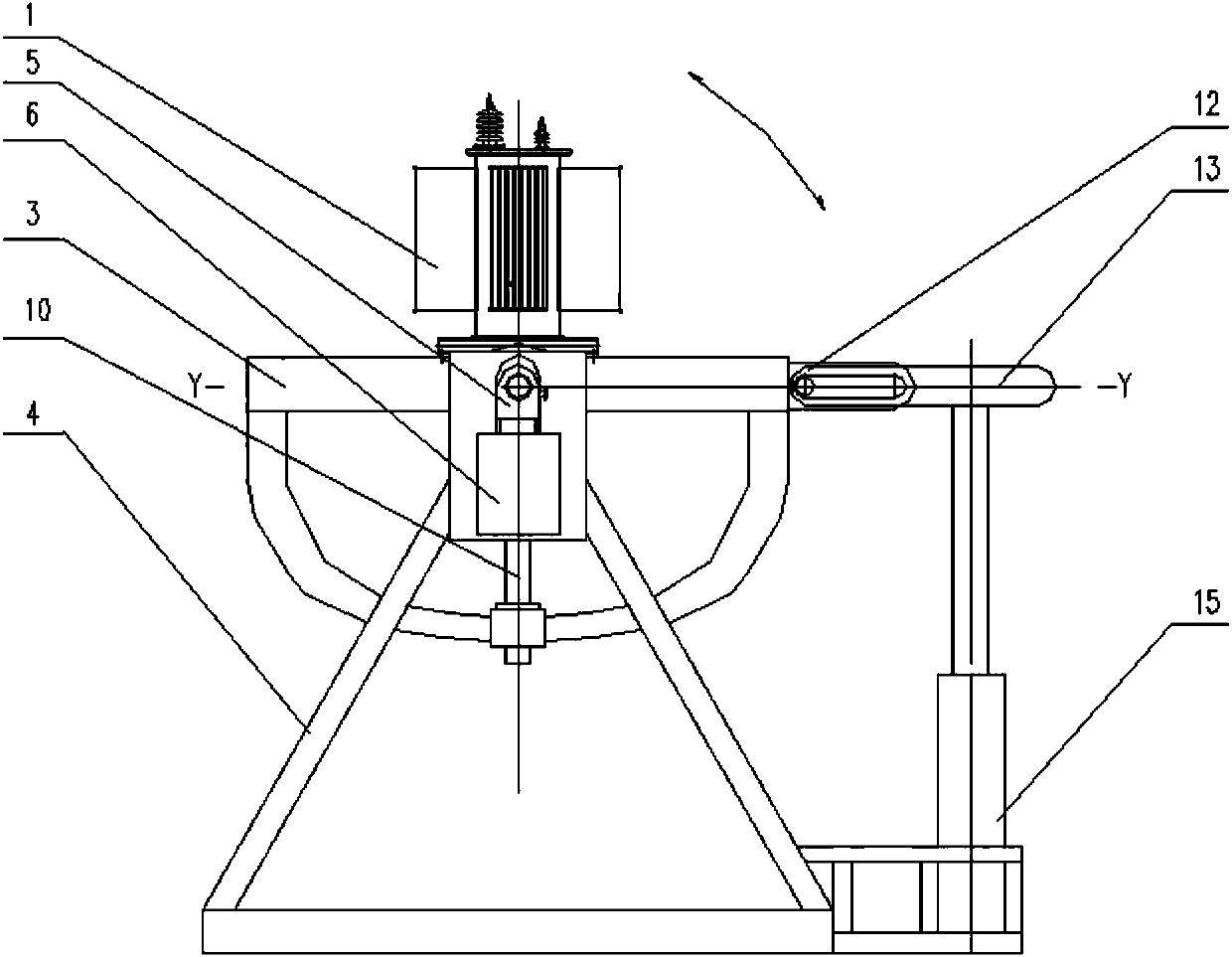

[0038] In this embodiment, the test bench is used to simulate the impact of the road transport vehicle on the transformer when climbing or descending the slope:

[0039] Driven by a second hydraulic cylinder 15, the disc bracket 3 moves up and down through the round shaft at the front end of the oil cylinder connecting rod 13, and the round shaft will slide in the rotary connection chute 12 of the disc bracket, driving the disc bracket 3 Rotating 20° around the X axis drives the transformer 1 on the table of the rotating disk 2 to tilt 20°. Generally, the maximum gradient of a truck should be 30%, that is, about 16.7°. The principle is: the transformer is tilted 20° on the rotating disk, and it will bear the lateral impact force and inertial force brought by a part of gravity, which can simulate the impact on the transformer when the car climbs and descends the slope.

Embodiment 3

[0041] In this embodiment, the test bench is used to simulate the impact of road transport vehicle bumps on the transformer:

[0042] The round shaft of the disc bracket is installed in the round hole of the slider 5, and the first hydraulic cylinder 6, 16 synchronously drives the slider 5 to reciprocate up and down, the stroke is 25.4mm (1 inch), the frequency is 0-6Hz, and the transformer 1 is driven along the Z The axis moves up and down. The principle is: the up-and-down movement of the stroke and frequency makes the transformer withstand the impact of the up-and-down movement, simulating the impact of the bumps in the transportation process of the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com