Gas catalytic flameless heating voc treatment system for paint film drying chamber

A gas catalysis and treatment system technology, applied in drying, drying machines, heating devices, etc., can solve the problems of large consumption of consumables, high operating costs, and heavy workload of activated carbon, achieving high efficiency and thorough exhaust gas treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

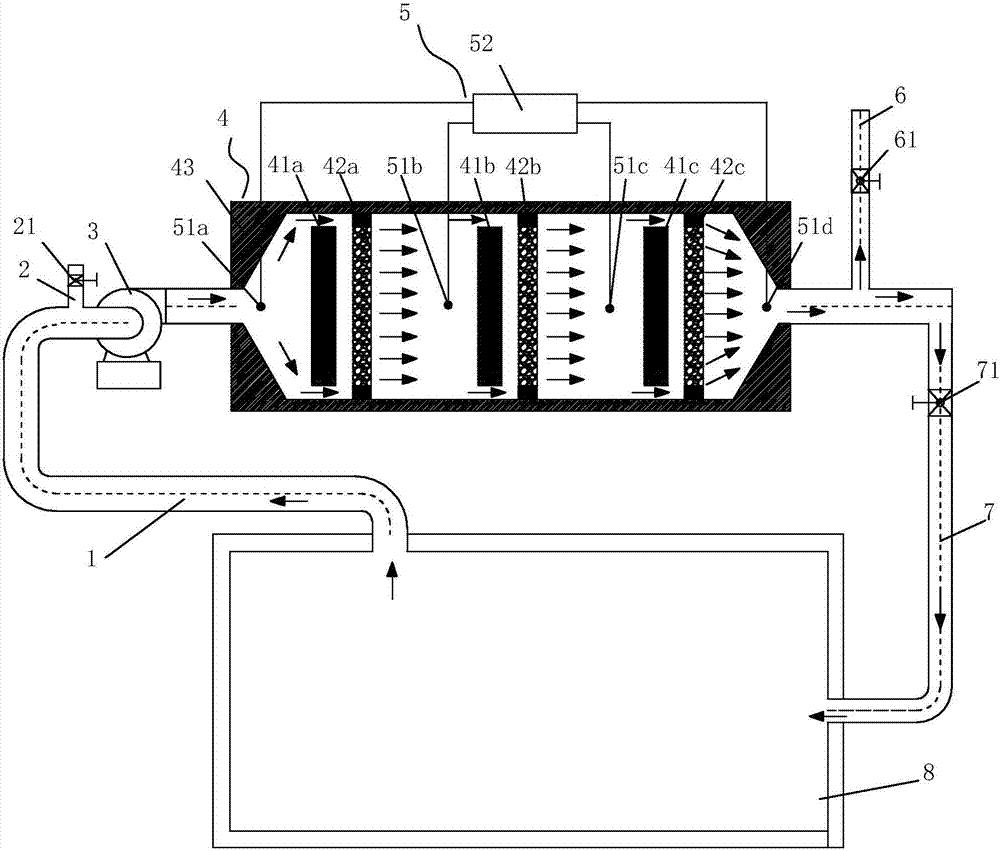

[0050] A gas catalytic flameless heating VOC treatment system in a paint film drying chamber (see figure 1 ), including exhaust fan 3, gas catalytic flameless infrared heating catalytic processor 4, VOC online detection system 5, return air duct 7, of which:

[0051]The air inlet of described exhaust fan 3 is connected with the waste gas outlet of paint film drying chamber 8 by exhaust pipe 1, and the entrance of exhaust fan 3 is equipped with fresh air inlet pipe 2, and fresh air inlet pipe 2 is installed on this fresh air inlet pipe 2. Gas regulating valve 21; the air outlet of the exhaust fan 3 is connected to the inlet of the gas catalytic flameless infrared heating catalytic processor 4 through the air pipe, and the outlet of the gas catalytic flameless infrared heating catalytic processor 4 is connected to the paint film drying through the return air pipe 7 The purification gas recovery port of chamber 8 is connected, and the return air pipe 7 is also provided with a pur...

Embodiment 2

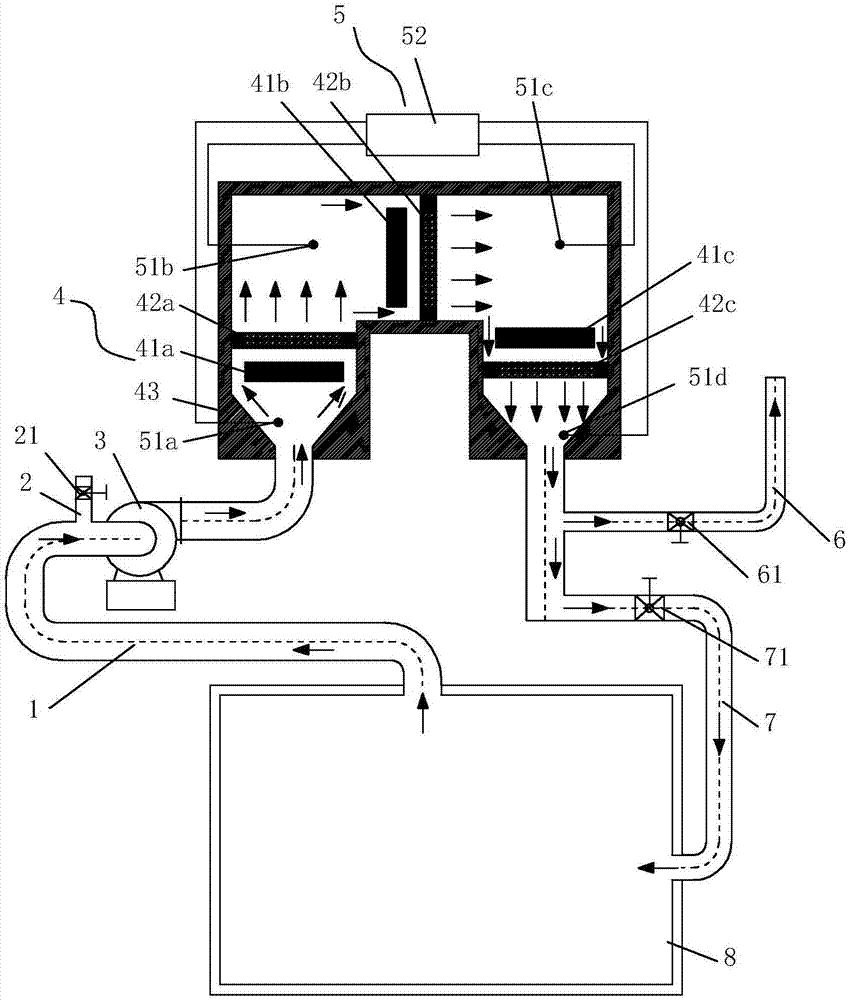

[0058] A gas-fired catalytic flameless heating VOC treatment system in a paint film drying chamber, the basic structure of which is the same as that of Embodiment 1, including an exhaust fan 3, a gas-fired catalytic flameless infrared heating catalytic processor 4, a VOC online detection system 5, and a return air Pipe 7, the difference is that: the three sets of heating catalytic combustion devices of the gas catalytic flameless infrared heating catalytic processor 4 are arranged in a U shape (see figure 2 ).

[0059] Instructions for use of the gas catalytic flameless heating VOC treatment system in the paint film drying chamber:

[0060] In principle, the temperature of the exhaust gas discharged from the top of the paint film drying chamber can reach above 145 degrees, and it can directly enter the first set of heating catalytic combustion device of the gas catalytic flameless infrared heating catalytic processor for treatment without preheating, due to catalytic heat sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com