A modified coal-fired boiler

A technology of coal-fired boilers and boilers, which is applied in the direction of combustion ignition, combustion methods, and control of combustion, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

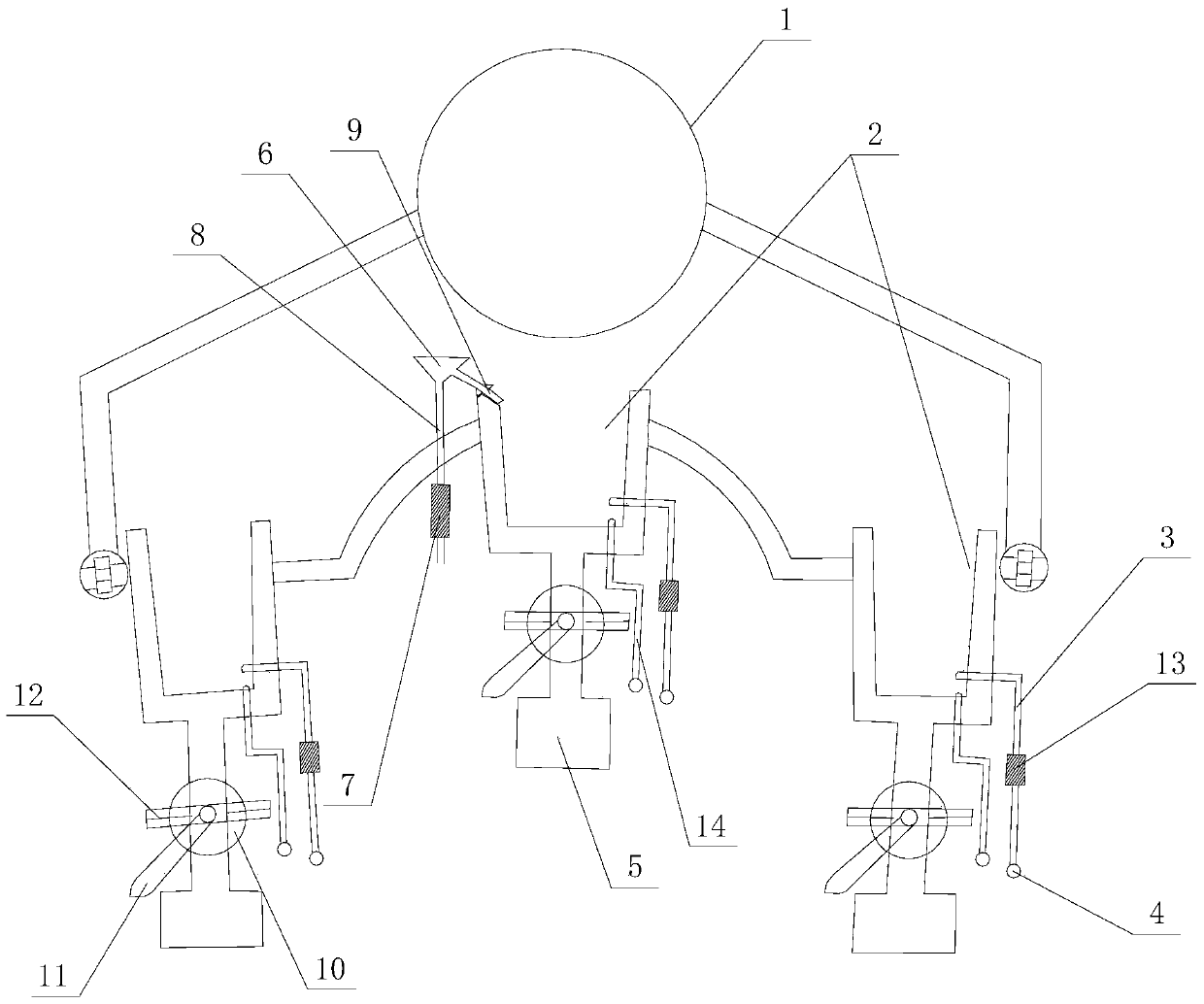

[0019] like figure 1 As shown, a modified coal-fired boiler includes a boiler furnace body 1, three burner heads 2 are arranged below the boiler furnace body 1, and the burner burner heads 2 are connected with a burner head inlet combustion liquid pipe 3, and the burner head inlet combustion liquid pipe 3 The end of the end is connected to the liquid inlet pipe 4, and the bottom of the burner burner 2 is provided with a blower air duct 5, and the burner burner 2 is also provided with an electronic ignition device. The electronic ignition device is composed of an electronic ignition drainage tank 6 and an electronic ignition transformer 7. The lower end of the electronic ignition drainage tank 6 is connected with a drainage tank filling pipe 8, and the electronic ignition transformer 7 is located at the lower end of the drainage tank filling tube 8. The electronic ignition drainage tank 6 passes through the lower end The fire pipe 9 is connected with the burner head 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com