Production method of Low-E glass and device thereof

A production method and technology of a production device are applied in the field of the production method and device of Low-E glass, and can solve the problem of high production cost of Low-E glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

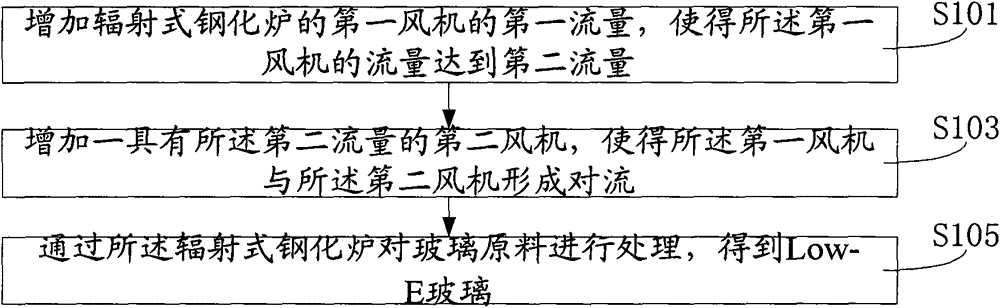

[0028] figure 1 A flowchart showing the production method of Low-E glass described in Embodiment 1 of the present invention.

[0029] see figure 1 As shown, the production methods of Low-E glass include:

[0030] S101: Increase the first flow rate of the first fan of the radiation tempering furnace so that the flow rate of the first fan reaches the second flow rate;

[0031] S103: Add a second fan with the second flow rate, so that the first fan and the second fan form a convection flow;

[0032] S105: Process the glass raw material through the radiation tempering furnace to obtain Low-E glass.

[0033] In step S101, the radiant tempering furnace is an ordinary radiant furnace, which is used to produce tempered white glass. Generally, an ordinary glass production factory will have an ordinary radiant furnace, and the fan of the ordinary radiant furnace, that is, the air flow of the first fan, is increased. Taking the centrifugal blower as an example, the centrifugal blower...

Embodiment 2

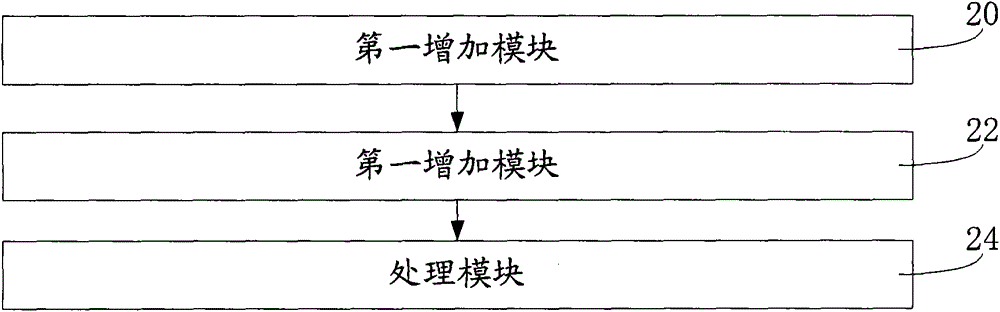

[0046] figure 2 It shows the structural schematic diagram of the production device of Low-E glass described in the second embodiment of the present invention.

[0047] see figure 2 As shown, the production device of Low-E glass includes: a first increasing module 20, which is used to increase the first flow of the first blower of the radiation tempering furnace, so that the flow of the first blower reaches the second flow; the second increase Module 22, for adding a second blower with the second flow rate, so that the first blower and the second blower form convection; processing module 24, for processing glass raw materials through the radiation tempering furnace processing to obtain Low-E glass.

[0048] Preferably, the processing module 24 includes: a first processing module (not shown in the figure), which is used to process the glass raw material for the first time through the radiation tempering furnace to obtain tempered white glass; a second processing module (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com